Abstract

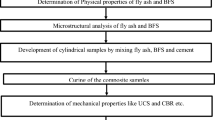

In this study, it investigated the effects of adding a mixture of circulating fluidized bed co-fired fly ash and bottom ash on controlled low-strength material (CLSM). Experiment variables were as follows: (1) mixing of co-fired fly ash, cement, and pulverized coal fly ash in various proportions to evaluate the effectiveness of using co-fired fly ash as cementitious material in CLSM; (2) mixing of bottom ash and natural fine aggregate in various proportions to evaluate the effectiveness of using bottom ash mixture as aggregates in CLSM. The water-cement ratio of CLSM was fixed at 0.85. Assessments were conducted using a lump flow test, flow consistency test, ball drop test, chloride ion measurement, compression strength test, and length change test. Test results indicate the following: (1) increasing the replacement ratio of co-fired fly ash and bottom ash decreases flowability; (2) the addition of co-fired ash (containing chlorine), with bottom ash increases the amount of chloride ions in CLSM; (3) the addition of co-fired fly ash reduces setting time; (4) the CaO, SiO2, and Al2O3 in co-fired fly ash and bottom ash increase the compressive strength of CLSM; (5) the CaO contained in the mixture of co-fired fly ash and bottom ash causes CLSM to expand.

Graphical abstract

Similar content being viewed by others

References

Monkman S, MacDonald M (2016) Const Build Mater 124:127

Cement Sustainability Initiative (2009) Cement industry energy and CO2 performance—getting the numbers right. World Bus Counc Sustain Dev

Omosebi O, Maheshwari H, Ahmed R, Shah S, Osisanya S, Hassani S, DeBruijn G, Cornell W, Simon D (2016) Cem Concr Compos 74:54

Rivera F, Martínez P, Castro J, López M (2015) Cem Concr Compos 63:104

Wu T, Chi M, Huang R (2014) Const Build Mater 66:172

Shen Y, Qian J, Zhang Z (2013) Const Build Mater 40:672

Dung NT, Chang TP, Chen CT (2014) Const Build Mater 63:40

Chi M (2016) Const Build Mater 123:565

Nguyen HA, Chang TP, Shih JY, Chen CT, Nguyen TD (2016) Const Build Mater 106:670

Muhmood L, Vitta S, Venkateswaran D (2009) Cem Concr Res 39:102

Chen BR (2009) Influence of pozzolanic materials on concrete. Taiwan Railways Administration, Ministry of Transportation and Communications

Le NLB, Stroeven M, Sluys LJ, Stroeven PV (2013) Comp Mater Sci 78:12

Wiles CC (1996) J Hazard Mater 47:325

Guidelines for Industrial Waste Recycling and Management (2002) Industrial Development Bureau, Ministry of Economic Affairs, Executive Yuan, Taiwan

Guidelines for General Waste Recycling and Disposal (2002) Environmental Protection Administration, Executive Yuan, Taiwan

Tseng YW (2014) Development status and future prospects of industrial waste recycling industry in Taiwan. Foundation of Taiwan Industry Service

Study for standardizes outlines of utilization the waste materials on highway engineering (2009) Ministry of Transportation and Communications, Executive Yuan, Taiwan

Wang HY, Chen KW (2016) Const Build Mater 102:422

Naganathan S, Razak HA, Hamid SNA (2012) Mater Des 33:56

Chapter 03377: Controlled low-strength material (CLSM) (2016) Public Construction Commission, Executive Yuan, Taiwan

American Concrete Institute, Committee 229, Controlled Low-Strength Materials (CLSM) ACI 229R-94 Report (1994)

Gabr MA, Bowders JJ (2002) J Hazard Mater 76:251

Katz A, Kovler K (2004) Waste Manag 24:501

Razak HA, Naganathan S, Hamid SNA (2009) J Hazard Mater 172:862

Tripathi H, Pierce CE, Gassman SL, Brown TW (2004) J ASTM Int 1:74

Wu JY, Lee MZ (2011) Int J Pavement Res Technol 4:293

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weng, TL., Lin, WT. & Liu, YL. Engineering properties of controlled low-strength materials containing co-fired fly ash. Monatsh Chem 148, 1337–1347 (2017). https://doi.org/10.1007/s00706-017-1925-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-017-1925-9