Abstract

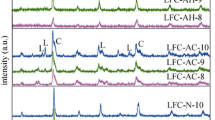

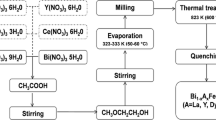

Nano-sized LaFeO3 powders were prepared first time by glycine–nitrate combustion process at different temperatures without using water or any other solvent for the preparation of precursor solution and thus avoids impurities caused by water completely. The structures of phases, calcined at different temperatures, were refined in the space group Pbnm with orthorhombic setting and a good agreement was obtained between the observed and calculated XRD patterns. The crystallite size and specific surface area during the decomposition process were monitored up to 1200 °C. A pure nano-sized LaFeO3 powder with high specific surface area of 18.30 m2/g and a crystallite size of 49.35 nm was obtained after calcination at 400 °C, while TEM investigations reveal a porous powder with particles in the range of 46–69 nm. Calcinations to 1200 °C result in crystallite sizes up to 82.35 nm. Magnetic measurements reveal that LaFeO3 powders are anti-ferromagnetic. Both magnetic susceptibility and effective magnetic moments of the samples increase with decreasing particle size because of an increasing fraction of atoms lie at or near the surface.

Graphical abstract

Similar content being viewed by others

References

Minh NQ (1993) J Am Ceram Soc 76:563

Delmastro A, Mazza D, Ronchetti S, Vallino M, Spinicci R, Brovetto P, Salis M (2001) Mater Sci Eng B 79:14

Ming Q, Nersesyan MD, Wagner A, Ritchie J, Richardson JT, Luss D, Jacobson AJ, Yang YL (1999) Solid State Ionics 122:113

Arakawa T, Kurachi H, Shiokawa J (1985) J Mater Sci 20:1207

Shimizu Y, Shimabukuro M, Arai H, Seiyama T (1985) Chem Lett 163:917

Martinelli G, Carotta MC, Ferroni M, Sadaoka Y, Traversa E (1999) Sens Actuators B 55:99

Seo JW, Fullerton EE, Nolting F, Scholl A, Fompeyrine J, Locquet J-P (2008) J Phys: Condens Matter 20:264014

Geller S, Raccah PM (1970) Phys Rev B 2:1167

Köferstein R, Jäger L, Zenkner M, Müller T, Abicht H-P (2008) Mater Chem Phys 112:531

Orlov AV, Shlyakhtin OA, Vinokurov AL, Knotko AV, Tret’yakov YD (2005) Inorg Mater 41:1194

Kondakindi RR, Karan K, Peppley BA (2012) Ceram Int 38:449

Larson AC, Von Dreele RB (2004) General structure analysis system (GSAS). Los Alamos National Laboratory Report LAUR 86-748

Prado-Gonjal J, Arévalo-López ÁM, Morán E (2011) Mater Res Bull 46:222

Wang J, Liu Q, Xue D, Li F (2002) J Mater Sci Lett 21:1059

Kumar M, Srikanth S, Ravikumar B, Alex TC, Das SK (2009) Mater Chem Phys 113:803

Köferstein R, Ebbinghaus SG (2013) Solid State Ionics 231:43

Shannon RD (1976) Acta Crystallogr A 32:751

Georgea M, Johna AM, Naira SS, Joyb PA, Anantharamana MR (2006) J Magn Magn Mater 302:190

Laberty C, Alphonse P, Demai JJ, Sarda C, Rousset A (1997) Mater Res Bull 32:249

Rezlescu N, Rezlescu E, Popa PD, Popovici E, Doroftei C, Ignat M (2013) Mater Chem Phys 137:922

Vasoya NH, Vanpariya LH, Sakariya PN, Timbadiya MD, Pathak TK, Lakhani VK, Modi KB (2010) Ceram Int 36:947

Shter GE, Schwartzman AR, Grader GS (1995) Appl Supercond 3:543

Andoulsi R, Horchani-Naifer K, Férid M (2012) Cerâmica 58:126

Nakayama S (2001) J Mater Sci 36:5643

Yan J-Q, Zhou J-S, Goodenough JB (2004) Phys Rev B 70:014402

Harada A, Taniyama T, Takeuchi Y, Sato T, Kyômen T, Itoh M (2007) Phys Rev B 75:184426

Thirumalairajan S, Girija K, Mastelaro VR, Ponpandian N (2015) J Mater Sci: Mater Electron 26:8652

Jain SR, Adiga KC, Verneker VRP (1981) Combust Flame 40:71

Phadatare MR, Salunkhe AB, Khot VM, Sathish CL, Dhawale DS, Pawar SH (2013) J Alloys Compd 546:314

Li J, Kou X, Qin Y, He H (2002) Phys Stat Sol 191:255

Acknowledgments

Authors are thankful to University Grants Commission, New Delhi for financial support under the UGC Major Research Project (F.No. 41-284/2012SR; dated 13.07.2012). Authors are also thankful to Dr. Harpreet Singh, Central Research Facility Section, Indian Institute of Technology Ropar, for recording XRD. Thanks are also due to Prof. Ramesh Chandra, Institute Instrumentation Centre, Indian Institute of Technology, Roorkee, for recording EDX, SEM and TEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., Singh, D. Synthesis of LaFeO3 nanopowders by glycine–nitrate process without using any solvent: effect of temperature. Monatsh Chem 148, 879–886 (2017). https://doi.org/10.1007/s00706-016-1818-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-016-1818-3