Abstract

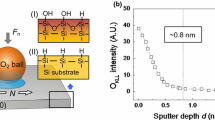

In this work, the effect of surface roughness and cleaning procedures on reactivity during priming with hexamethyldisilazane is described for four silicon substrates frequently used in semiconductor technology, namely thermally grown SiO2, argon implanted tetraorthosilicate SiO2, polysilicon, and amorphous silicon. Surface energy and roughness were determined by static contact angle measurements and atomic force microscopy. The surface roughness of the silicon substrates increased in the order: thermally grown SiO2, argon implanted tetraorthosilicate SiO2, polysilicon, and amorphous silicon. It was found not to be substantially affected by standard cleaning procedures. The surface energy of all silicon samples decreased with increasing hexamethyldisilazane vapor exposure at 90 °C, and the extent of the decrease corresponded to the surface roughness. Furthermore, a promoting effect on the silylation reaction by an argon implantation process was determined. A correlation between the surface morphology of different silicon materials and reactivity in the silylation reaction with hexamethyldisilazane could be established.

Graphical abstract

Similar content being viewed by others

References

Schneiderman R (2011) IEEE Signal Process Mag 28:8

Franssila S (2004) Introduction to microfabrication. Wiley, Chichester

Li N, Ho C-M (2008) Lab Chip 8:2105

Sackmann E, Tanaka M (2000) Trends Biotechnol 18:58

Rehfeldt F, Tanaka M, Pagnoni L, Jordan R (2002) Langmuir 18:4908

Schultz J, Nardin M (2003) Theories and mechanisms of adhesion. In: Pizzi A, Mittal KL (eds) Handbook of adhesive technology, 2nd edn. Marcel Dekker Inc, New York

Blossey R (2003) Nat Mater 2:301

Khanna VK (2011) J Phys D Appl Phys 44:034004

Petersson L, Meier P, Kornmann X, Hillborg H (2011) J Phys D Appl Phys 44:034011

Lampin M, Warocquier-Clerout R, Legris C, Degrange M, Sigot-Luizard MF (1997) J Biomed Mater Res Part A 36:99

Kern W (2008) Evolution of wafer cleaning science and technology. In: Kern W, Reinhardt KA (eds) Handbook of semiconductor wafer cleaning technology, 2nd edn. William Andrew Inc, Norwich, p 47

Kern W, Puotinen DA (1970) RCA Rev 31:187

Sato M, Kawai A (2006) J Photopolym Sci Tec 19:601

Ponjeé JJ, Mariott VB, Michielsen MCBA, Touwslager FJ, van Velzen PNT, van der Wel H (1990) J Vac Sci Technol B 8:463

Bauer J, Drescher G, Illig M (1996) J Vac Sci Technol B 14:2485

Larsson MP, Ahmad MM (2006) J Micromech Microeng 16:161

Hertl W, Hair ML (1971) J Phys Chem 75:2181

Gun’ko VM, Vedamuthu MS, Henderson GL, Blitz JP (2000) J Colloid Interface Sci 228:157

Hwang K-Y, Park C-S, Kim J-H, Suh K-Y, Cho E-C, Huh N (2010) J Micromech Microeng 20:117001

Helbert JN, Saha NC (1984) Importance of the interface condition upon photoresist image adhesion in microelectronic device fabrication. In: Bowden MJ, Turner SR (eds) Polymers for high technology electronics and photonics. ACS Symposium Series, Washington DC

Hair ML, Hertl W (1973) J Phys Chem 75:1965

Samitsu Y (1993) Nanotechnology 4:236

Busscher HJ, van Pelt AWJ, de Boer P, de Jong HP, Arends J (1984) Colloids Surf 9:319

Vesel A, Junkar I, Cvelbar U, Kovac J, Mozetic M (2008) Surf Interface Anal 40:1444

Chasse M, Ross GG (2002) J Appl Phys 92:5872

Feng B, Weng J, Yang BC, Qu SX, Zhang XD (2003) Biomaterials 24:4663

Ström G, Frederiksson M, Stenius P (1986) J Coll Interface Sci 119:352

Leenaars AFM, Huethorst JAM, van Oekel JJ (1990) Langmuir 6:1701

Widmann D, Mader H, Friedrich H (2000) Technology of integrated circuits. Springer, Heidelberg, p 247

Friedbacher G, Fuchs H (2003) Angew Chem 115:5804

Lee JP, Jang YJ, Sung MM (2003) Adv Funct Mater 13:873

Yang SY, Shin K, Park CE (2005) Adv Funct Mater 15:1806

Cho K, Kim D, Yoon S (2003) Macromolecules 36:7652

Owens DK, Wendt RC (1969) J Appl Polym Sci 13:1741

Rabel W (1971) Farbe Lack 77:997

Kaelble DH (1970) J Adhes 2:66

Lau WS (1999) Infrared characterization for microelectronics. World Scientific, Singapore, p 25

Barr TL, Seal S (1995) J Vac Sci Technol A 13:1239

Acknowledgments

This study was performed at the Institute for Chemistry and Technology of Materials (ICTM) at the Graz University of Technology and at Infineon Technologies Austria AG Villach with funding and contributions from the Polymer Competence Center Leoben GmbH (PCCL, Austria) within the framework of the COMET-program of the Austrian Ministry of Traffic, Innovation and the Ministry of Economy, Family and Youth. PCCL is funded by the Austrian Government and the State Governments of Styria and Upper Austria.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bodner, T., Behrendt, A., Prax, E. et al. Correlation of surface roughness and surface energy of silicon-based materials with their priming reactivity. Monatsh Chem 143, 717–722 (2012). https://doi.org/10.1007/s00706-012-0730-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-012-0730-8