Abstract

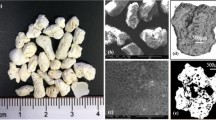

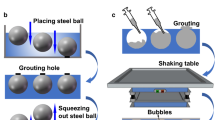

Particle crushing is a fundamental issue in the analysis of the deformation and failure behaviour of rockfill materials. The impact of morphology on the crushing behaviour of granite particles is investigated via a series of in-situ X-ray micro-CT tests and DEM simulations. Single-particle crushing tests are performed on rock particles of three different sizes. During mechanical loading, four in-situ CT scans are performed on each grain using an innovative loading apparatus. The CT test images reveal that the shape of the particle and its heterogeneous structure are crucial factors in determining failure patterns. Additionally, various shape indexes of rock particles change progressively and tend to stabilize, while their fragments follow a fractal distribution, seemingly independent of their initial size. Based on CT images, numerical particles with realistic shapes and internal flaws are generated using a proposed numerical method. It is observed that an increase in elongation index EI or flatness index FI results in a decrease in characteristic strength \(\sigma _0\) and an increase in Weibull modulus m.

Highlights

-

A novel loading apparatus has been developed for the realization of in-situ \(\mu\)CT scans during single-particle crushing tests.

-

CT test images reveal that particle shape and its heterogeneous structure are crucial factors in determining the failure pattern of rockfill particles.

-

A new numerical method is proposed for generating particles, including both particle shape and microstructure.

-

For particle shape, increasing the elongation index and flatness index of particle results in a decrease in characteristic strength \(\sigma _0\) and an increase in Weibull modulus m.

Similar content being viewed by others

Data availability

The data are available from the corresponding author on reasonable request.

References

Alam MF, Haque A, Ranjith PG (2018) A study of the particle-level fabric and morphology of granular soils under one-dimensional compression using insitu x-ray ct imaging. Materials 11:919

An N, Ma G, Zhou H, Wang D, Lu X, Zhou W (2023) Dem investigation of the microscopic mechanism of scale effect of sandy gravel material. Acta Geotech 18:1373–1390

Andò E, Viggiani G, Hall S, Desrues J (2013) Experimental micro-mechanics of granular media studied by x-ray tomography: recent results and challenges. Géotech Lett 3:142–146

Cavarretta I, O’sullivan C (2012) The mechanics of rigid irregular particles subject to uniaxial compression. Géotechnique 62:681–692

Cil MB, Alshibli KA (2012) 3d assessment of fracture of sand particles using discrete element method. Géotech Lett 2:161–166

Cil MB, Alshibli KA (2014) 3D evolution of sand fracture under 1D compression. Géotechnique 64:351–364

Daouadji A, Hicher PY (2010) An enhanced constitutive model for crushable granular materials. Int J Numer Anal Methods Geomech 34:555–580

Daouadji A, Hicher PY, Rahma A (2001) An elastoplastic model for granular materials taking into account grain breakage. Eur J Mech A Solid 20:113–137

Das GK (2016) Sediment Grain Size. Springer Netherlands, Dordrecht. pp. 555–558. https://doi.org/10.1007/978-94-017-8801-4_148

de Bono JP, McDowell GR (2016) The fractal micro mechanics of normal compression. Comput Geotech 78:11–24

Domokos G, Sipos AÁ, Szabó T (2012) The mechanics of rocking stones: equilibria on separated scales. Math Geosci 44:71–89

Drlik GJ (1987) Simulation of the crushing of a two-dimensional particle bed due to compressive loading. Ph.D. thesis. Massachusetts Institute of Technology, USA

Duriez J, Scholtès L, Donzé FV (2016) Micromechanics of wing crack propagation for different flaw properties. Eng Fract Mech 153:378–398

Fang C, Gong J, Jia M, Nie Z, Hu W, Li B (2022) Effect of the intermediate principal stress on the mechanical behaviour of breakable granular materials using realistic particle models. Acta Geotech 17:4887–4904

Fang C, Gong J, Jia M, Nie Z, Li B, Mohammed A (2022) Investigating the effects of elongation and flatness on the shear behaviour of breakable granular materials via the dem. Granul Matter 24:78

Fonseca J, O’sullivan C, Coop MR, Lee P (2012) Non-invasive characterization of particle morphology of natural sands. Soils Found 52:712–722

Fu R, Hu X, Zhou B (2017) Discrete element modeling of crushable sands considering realistic particle shape effect. Comput Geotech 91:179–191

Guida G, Casini F, Viggiani GM, Ando E, Viggiani G (2018) Breakage mechanisms of highly porous particles in 1D compression revealed by X-ray tomography. Géotech Lett 8:155–160

Honkanadavar N, Sharma K (2014) Testing and modeling the behavior of riverbed and blasted quarried rockfill materials. Int J Geomech 14:04014028

Huang Q, Zhou W, Ma G, Ng TT, Xu K (2020) Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci Front 11:401–411

Jaeger JC (1967) Failure of rocks under tensile conditions. Int J Rock Mech Min Sci 4:219–227

Jansen U, Stoyan D (2000) On the validity of the Weibull failure model for brittle particles. Granul Matter 2:165–170

Jolliffe I (2005) Principal component analysis. In: Everitt B, Howell D (eds) Encyclopedia of statistics in behavioral science. Wiley. https://doi.org/10.1002/0470013192.bsa501

Kozicki J, Donze FV (2008) A new open-source software developed for numerical simulations using discrete modeling methods. Comput Method Appl Mech Eng 197:4429–4443

Kozicki J, Donze FV (2009) YADE-OPEN DEM: an open-source software using a discrete element method to simulate granular material. Eng Comput 26:786–805

Lee DM (1992) The angles of friction of granular fills. Ph.D. thesis. University of Cambridge, UK

Li L, Beemer RD, Iskander M (2021) Granulometry of two marine calcareous sands. J Geotech Geoenviron 147:04020171

Lim WL, McDowell GR, Collop AC (2004) The application of Weibull statistics to the strength of railway ballast. Granul Matter 6:229–237

Limodin N, Rougelot T, Hosdez J (2013) ISIS4D—in situ innovative set-ups under X-ray microtomography. http://isis4d.univ-lille.fr/ Univ Lille, Villeneuve d’Ascq

Lobo-Guerrero S, Vallejo LE (2006) Application of Weibull statistics to the tensile strength of rock aggregates. J Geotech Geoenviron 132:786–790

Ma G, Chen Y, Yao F, Zhou W, Wang Q (2019) Evolution of particle size and shape towards a steady state: insights from fdem simulations of crushable granular materials. Comput Geotech 112:147–158

McDowell GR (2001) Statistics of soil particle strength. Géotechnique 51:897–900

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42:139–145

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40:133–141

McDowell GR, Bolton MD (1998) On the micromechanics of crushable aggregates. Géotechnique 48:667–679

McDowell G, Daniell C (2001) Fractal compression of soil. Géotechnique 51:173–176

Meng M, Xiao Y, Duan X, Sun Z, Du L, Fan H, Liu H (2022) Crushing strength of artificial single-particle considering the effect of particle morphology. Acta Geotech 17(9):3909–26

Mora C, Kwan A (2000) Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem Concr Res 30:351–358

Nakata AFL, Hyde M, Hyodo H, Murata (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49:567–583

Nakata Y, Kato Y, Hyodo M, Hyde AF, Murata H (2001) One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found 41:39–51

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher PY (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225:2199–2216

Potyondy DO (2023) Material-modeling support in PFC [fistPkg7.3], Itasca Consulting Group, Inc., Technical Memorandum ICG7766-L (June 29, 2023), Minneapolis. https://www.itascacg.com/software/material-modeling-support/

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Quinn GD (2007) Fractography of ceramics and glasses, vol 960. National Institute of Standards and Technology, Washington, DC

Rozenblat Y, Portnikov D, Levy A, Kalman H, Aman S, Tomas J (2011) Strength distribution of particles under compression. Powder Technol 208:215–224

Scholtès L, Donzé FV (2013) A DEM model for soft and hard rocks: role of grain interlocking on strength. J Mech Phys Solids 61:352–369

Shao X, Chi S, Tao Y, Zhou X (2020) Dem simulation of the size effect on the wetting deformation of rockfill materials based on single-particle crushing tests. Comput Geotech 123:103429

Shi Y, WM Y, Mukunoki T, Sato T, Otani J (2016) A microscopic investigation into the breakage behavior of calcareous origin grains in 1d compression. Geotech Soc Spec Publ 2:630–634

Shlens J (2014) A tutorial on principal component analysis. arXiv:1404.1100

Smith LI (2002) A tutorial on principal components analysis. Technical Report. Department of Computer Science, Univ Otago, New Zealand

Turcotte DL (1986) Fractals and fragmentation. J Geophys Res Solid Earth 91:1921–1926

Wang J, Yan H (2011) On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int J Numer Anal Methods Geomech 37:832–854

Wang Y, Ma G, Mei J, Zou Y, Zhang D, Zhou W, Cao X (2021) Machine learning reveals the influences of grain morphology on grain crushing strength. Acta Geotech 16:3617–3630

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Xiao Y, Meng M, Daouadji A, Chen Q, Wu Z, Jiang X (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11:375–388

Xiao Y, Sun Y, Zhou W, Shi J, Desai CS (2022) Evolution of particle shape produced by sand breakage. Int J Geomech 22:04022003

Yoshimoto N, Hyodo M, Nakata Y, Orense RP, Hongo T, Ohnaka A (2012) Evaluation of shear strength and mechanical properties of granulated coal ash based on single particle strength. Soils Found 52:321–334

Zhang T, Zhang C, Yang Q, Fu R (2020) Inter-particle friction and particle sphericity effects on isotropic compression behavior in real-shaped sand assemblies. Comput Geotech 126:103741

Zhao B, Wang J, Coop MR, Viggiani G, Jiang M (2015) An investigation of single sand particle fracture using X-ray micro-tomography. Géotechnique 65:625–641

Zhao X, Zhu J, Jia Y, Colliat JB, Bian H, Zhang Q (2022) Experimental and numerical study of size effects on the crushing strength of rockfill particles. Int J Numer Anal Methods Geomech 46:2060–2086

Zhao X, Zhu J, Wu Y, Jia Y, Colliat JB, Bian H (2022) A numerical study on the influence of coordination number on the crushing of rockfill materials. Rock Mech Rock Eng 55:6279–6300

Zhou MJ (2021) A crack theory-based bonded-particle model for rock particles considering size effects. Géotech Lett 11:340–349

Zhou B, Wang J (2015) Random generation of natural sand assembly using micro x-ray tomography and spherical harmonics. Géotech Lett 5:6–11

Zhou B, Wang J (2017) Generation of a realistic 3d sand assembly using x-ray micro-computed tomography and spherical harmonic-based principal component analysis. Int J Numer Anal Methods Geomech 41:93–109

Zhou B, Wang J, Zhao B (2015) Micromorphology characterization and reconstruction of sand particles using micro x-ray tomography and spherical harmonics. Eng Geol 184:126–137

Zhou W, Yang L, Ma G, Chang X, Lai Z, Xu K (2016) DEM analysis of the size effects on the behavior of crushable granular materials. Granul Matter 18:1–11

Zhou B, Wang J, Wang H (2018) Three-dimensional sphericity, roundness and fractal dimension of sand particles. Géotechnique 68:18–30

Acknowledgements

The authors gratefully acknowledge the financial support from the State Key Program of National Natural Science Foundation of China (No. U2040221), the Open Sharing Fund for the Large-scale Instruments of Hohai University (Nos. GX202205B; GX202204B), and the 111 Project (No. B13024). The first author gratefully acknowledges the financial support from China Scholarship Council (No. 201806710020). The CT tests were completed at the ISIS4D X-Ray CT platform, University of Lille. This platform has been funded by the International Campus on Safety and Inter-modality in Transportation (CISIT), the Hauts-de-France Region, the European Community and the National Center for Scientific Research (CNRS). Special thanks are addressed to Jérôme Hosdez for his invaluable assistance to the preparation of samples. The single-particle crushing test simulations are performed on the Mésocentre de Lille. The authors gratefully thank the anonymous reviewers for their constructive comments as well.

Funding

Financial support from the National Natural Science Foundation of China (No. U2040221), the Open Sharing Fund for the Large-scale Instruments of Hohai University (Nos. GX202205B; GX202204B), and the 111 Project (No. B13024).

Author information

Authors and Affiliations

Contributions

Xiaolong Zhao: conceptualization, methodology, investigation, software, writing—original draft, funding acquisition. Yunlong Wu: investigation, methodology, writing—review and editing. Yun Jia: conceptualization, methodology, supervision, writing—review and editing. Hanbing Bian: methodology, writing—review and editing. Nicolas Bur: investigation, writing—review and editing. Jungao Zhu: writing—review and editing, funding acquisition. Jean-Baptiste Colliat: methodology, supervision, writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, X., Wu, Y., Jia, Y. et al. Impact of Particle Shape on Crushing Behaviour of Rock Particles Using X-ray Micro-CT Testing and DEM Modelling. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-024-03916-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-024-03916-4