Abstract

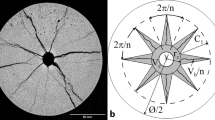

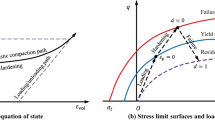

The presence of numerous open joints and complex three-dimensional (3D) geometrical characteristics in natural rock masses creates structural discontinuities that significantly impact stress-wave propagation and the rock’s damage and failure behaviors. In this study, specimens featuring open joints were prepared using 3D printing techniques, and an indoor 3D blasting experiment was conducted at dig angles of 50°, 70°, and 90°. Computed tomography (CT) scans and subsequent 3D reconstructions were employed to analyze the 3D distribution of cracks in the blasted specimens. The blasting process on a rock mass with open joints was inversely deduced using the numerical simulation software AUTODYN, considering the evolution of stress-wave propagation and blasting-induced damage as a function of the open joint dip angle. The results revealed the formation of blast-induced cracks primarily at the ends of the open joints, accompanied by circumferential cracks on the outer surface surrounding the projected joint profile. The incident angle of the stress wave compromised the stressed state at the joint ends, resulting in variations in crack distribution patterns on the back-blast side. As the joint dip angle increased, both the fractal dimension and specimen damage escalated, while the inhibitory effect of the 3D open joint face on crack propagation weakened. The dip angle of the joint face significantly influences the form and intensity of the stress wave. When the stress wave is vertically incident, bypassing waves at the lower and upper ends, along with the wave transmitted in the middle, cause the open joint face to close under stress. Consequently, the stress and damage fields exhibit a weakening effect on the side closer to the blast and an intensification effect on the opposite side.

Highlights

-

1.

Specimens featuring opening joints were prepared using 3D printing, and the fracture modes of joints with varying opening angles under blasting loads were examined.

-

2.

The spatial configuration of 3D cracks was reconstructed, and an analysis was conducted to determine how the opening joint angle influenced the spatial distribution of these cracks during rock blasting.

-

3.

A 3D numerical model of a rock mass with open joints was implemented, allowing analysis of the interaction between explosive stress waves and internal open joint planes. In addition, the evolution of damage within the rock mass was studied.

Similar content being viewed by others

Data availability

Relevant data can be obtained by contacting the corresponding author.

References

Cai JG, Zhao J (2000) Effects of multiple parallel fractures on apparent attenuation of stress waves in rock masses. Int J Rock Mech Min Sci 37(4):661–682

Chen HD, Cheng YP, Zhou HX et al (2013) Damage and permeability development in coal during unloading. Rock Mech Rock Eng 46(6):1377–1390

Ding YX, Wang ZL, Huang YP (2020) 3D simulation of stress wave propagation in jointed rock mass with filling joint. Hydro-Sci Eng 6:80–88

Ding CX, Yang RS, Yang LY (2021a) Experimental results of blast-induced cracking fractal characteristics and propagation behavior in deep rock mass. Int J Rock Mech Min Sci 142:104772

Ding CX, Yang RS, Feng C (2021b) Stress wave superposition effect and crack initiation mechanism between two adjacent boreholes. Int J Rock Mech Min Sci 138:104622

Ding CX, Yang RS, Lei Z et al (2021c) Fractal damage and crack propagation in decoupled charge blasting. Soil Dyn Earthq Eng 141:106503

Hajibagherpour AR, Mansouria H, Bahaaddini M (2020) Numerical modeling of the fractured zones around a blasthole. Comput Geotech 123:103535

Hu R, Zhu ZM, Zhang XY, Hu ZY, Zheng T (2012) Effect of joint orientation on rock blasting. J Sichuan Univ (Eng Sci Ed) 44(S2):41–44

Jiang C, Zhao GF, Zhu JB, Zhao YX, Shen LM (2016) Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech Rock Eng 49:3983–3998

Ju Y, Zheng JT, Epstein M et al (2014) 3D numerical reconstruction of well-connected porous structure of rock using fractal algorithms. Comput Methods Appl Mech Eng 279:212–226

Moon SK, Tan YE, Hwang J et al (2014) Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int J Precis Eng Manuf Green Technol 1(3):223

Sharafisafa M, Shen LM, Xu QF (2018) Characterisation of mechanical behaviour of 3D printed rock-like material with digital image correlation. Int J Rock Mech Min Sci 112:122

Song JF, Lu CP, Zhang XF, Guo Y, Yang HW (2022) Damage mechanism and wave attenuation induced by blasting in jointed rock. Geofluids 15:6950335

Tza B, Jbz B, Yjc D, Hpx E (2019) Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng Fract Mech 205:190–204

Wang YB, Ren B, Wang DC (2021) Research on the process of crack growth induced by explosion stress waves in rock masses with open joints. Theoret Appl Fract Mech 115:103038

Wei CH, Zhu WC, Bai Y, Li S (2016) Numerical simulation on two-hole blasting of rock under different joint angles and in-situ stress conditions. Chin J Theor Appl Mech 48(4):927–935

Xiao TS, Yang RS, Zhuang JZ, Li Q (2007) Dynamic caustics model experiment of blasting crack developing on sandwich rock. Explos Shock Waves 27(2):160–164

Yang RS, Wang YB, Ding CX (2016a) Laboratory study of wave propagation due to explosion in a jointed medium. Int J Rock Mech Min Sci 81:70–80

Yang RS, Xu P, Yang LY, Ding CX (2016b) Study of regularity of explosive stress wave propagation in jointed rock mass. Metal Mine 6:49–54

Zhang XL, Jiao YY, Liu QS, Liu BL (2008) Numerical study on effect of joints on blasting wave propagation in rock mass. Rock Soil Mech 3:717–721

Zhou XP, Zhang JZ, Wong L (2018) Experimental study on the growth coalescence and wrapping behaviors of 3D cross-embedded flaws under uniaxial compression. Rock Mech Rock Eng 51(5):1379–1400

Zhou T, Zhu J, Xie H (2020) Mechanical and volumetric fracturing behaviour of three-dimensional printing rock-like samples under dynamic loading. Rock Mech Rock Eng 53(6):2855–2864

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (Grant No. 2021YFC2902103), the National Natural Science Foundation of China (Grant No. 51934001), and the versities (grant No. 2023JCCXLJ02).

Funding

This study was funded by the National Key Research and Development Program of China (Grant No. 2021YFC2902103), Innovative Research Group Project of the National Natural Science Foundation of China (Grant No. 51934001), and the Fundamental Research Funds for the Central Universities (Grant No. 2023JCCXLJ02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there are no conflicts of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Luo, L., Wang, Z. et al. 3D Damage and Failure Patterns in Rock due to Blasting at Different Open Joints Dig Angles. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-024-03816-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-024-03816-7