Abstract

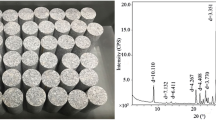

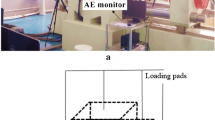

In order to improve the crushing efficiency of drilling machinery, laser-assisted mechanical rock-breaking technology has gained wide attention in the field of engineering construction. In this method, the weakening effect of the laser on the compressive strength of the rock is a key factor of the technology. To reveal the weakening effect of the laser on the compressive strength of rocks, standard uniaxial compression tests were carried out on irradiated rocks using a uniaxial compression testing machine. The weakening effect of laser power and irradiation time on rock strength and rock failure mode was investigated. The experimental results show that the laser power and irradiation time have similar effects on the mechanical properties of the rocks. With the increase of laser power and irradiation time, the peak stress of the specimens shows a tendency to decrease rapidly and then slowly. At the same time, the rock elastic modulus decreases and peak strain increases, and the behavior eventually transform from brittle damage to plastic damage. Melting pit holes and crack networks are the root cause of the weakness of the compressive strength. On one hand, the vertical melting pit hole provides a conical free surface, which reduces the rock deformation constraint and generates stress concentration at the bottom of the hole, so that it facilitates the splitting-tension damage of the specimen. On the other hand, the axial load induces symmetric tensile cracks in the thermal cracks, and adjacent tensile cracks interpenetrate to create a surface of tensile damage, leading to fragmentation of the specimen in the form of rock blocks, ultimately undermining the rock. This work provides an improved understanding of the effect of lasers on the compressive strength of rocks in engineering applications.

Highlights

-

The effect of laser irradiation on the compressive strength weakening of rock was investigated.

-

Failure modes and strength weakening mechanisms of irradiated rocks were revealed.

-

The advantage parameters of laser-assisted rock breaking were clarified.

Similar content being viewed by others

Data Availability

The data that support the fingdings of this study are available from the corresponding author upon reasonable request.

References

Ai T, Zhang R, Zhou HW, Pei JL (2014) Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl Surf Sci 314:610–621

Allaart P, Jones T (2023) Box-counting dimension and differentiability of box-like statistically self-affine functions. J Math Anal Appl 521(2):126909

Atlasov R, Nikolaeva M, Karamzin V (2019) Development of drilling and casing technologies for permafrost areas. IOP Conf Ser: Earth Environ Sci 272(2):022078

Cai M, Hou PY, Zhang XW, Fang XT (2021) Post-peak stress–strain curves of brittle hard rocks under axial-strain-controlled loading. Int J Rock Mech Min Sci 147:104921

Capik M, Yilmaz AO (2021) Development models for the drill bit lifetime prediction and bit wear types. Int J Rock Mech Min Sci 139:104633

Chen K, Huang ZQ, Deng R, Zhang WL, Kang MQ, Ma YC (2022a) Numerical simulation and test investigation on phase transition and thermal cracking process of sandstone by laser drilling. Rock Mech Rock Eng 55(4):2129–2147

Chen K, Huang ZQ, Deng R, Zhang WL, Kang MQ, Ma YC, Shi MJ, Yan J (2022b) Research on the temperature and stress fields of elliptical laser irradiated sandstone, and drilling with the elliptical laser-assisted mechanical bit. J Pet Sci Eng 211:110147

Dai XW, Huang ZW, Zou WC, Wu XG, Shi HZ (2021) Failure characteristics of rocks subjected to PDC cutter indentation. J Pet Sci Eng 207:108992

Fan XD (2019) Study on the technical problems and countermeasures of PDC bits in the drilling process of Triassic mudstone. West Resour 3:5 (In Chinese)

Fang TC, Ren FS, Wang BJ, Cheng JX, Liu HX (2021) Particle jet impact deep-rock in rotary drilling: failure process and lab experiment. PLoS ONE 16(4):e0250588

Guo CG, Sun Y, Yue HT, Li Q, He SZ, Zhang JZ, Zhang Y (2022) Experimental research on laser thermal rock breaking and optimization of the process parameters. Int J Rock Mech Min Sci 160:105251

Gupta A, Chattopadhyaya S, Hloch S (2013) Critical investigation of wear behaviour of WC drill bit buttons. Rock Mech Rock Eng 46:169–177

Han YN, Li XR, Feng YC (2020) A new approach to evaluate rock drillability of polycrystalline diamond compact bits using scratch test data. Energy Explor Exploit 38(4):884–904

Khaled MS, Chen MH, Losoya EZ, Rodriguez LA, Gildin E, Skelton RE (2022) Tensegrity laboratory drilling rig for earth and space drilling, mining, and exploration. Int J Solids Struct 252:111785

Kirli MS, Fahrioglu M (2019) Sustainable development of Turkey: deployment of geothermal resources for carbon capture, utilization, and storage. Energy Sources Part A-Recovery Util Environ Eff 41(14):1739–1751

Li B, Hu MM, Zhang B, Li NB, Shao W, Nie LC, Cao WZ, Xu B (2022a) Numerical simulation and experimental studies of rock-breaking methods for pre-grooving-assisted disc cutter. Bull Eng Geol Environ 81(3):90

Li B, Zhang B, Hu MM, Liu B, Cao WZ, Xu B (2022) Full-scale linear cutting tests to study the influence of pre-groove depth on rock-cutting performance by TBM disc cutter. Tunn Undergr Space Technol 122:104366

Li J, Du Q, Sun CX (2009) An improved box-counting method for image fractal dimension estimation. Pattern Recognit 42(11):2460–2469

Li J, Peng SJ, Xu J, Yan FZ, Zhou J, Chen JR (2022c) Novel multi-field coupling high-voltage electric pulse fracturing coal–rock permeability enhancement test system. Int J Rock Mech Min Sci 158:105180

Li MY, Han B, Zhang Q, Zhang SY, He QK (2019) Investigation on rock breaking for sandstone with high power density laser beam. Optik 180:635–647

Li Y, Chen ZJ, Ye YH, Yang YX (2021a) Combined finite-discrete element method for modeling the interaction between single PDC cutter and brittle rock. J Pet Sci Eng 207:109133

Li YL, Peng JM, Zhang PY, Huang CY (2021b) Hard rock fragmentation in percussion drilling considering confining pressure: insights from an experimental study. Int J Rock Mech Min Sci 148:104961

Liu B, Zhang J, Wang JH, Li WX, Li SA (2020) Technologies for the safe and efficient drilling of ultradeep wells in the areas with intrusive rocks in the Shunbei Oilfield. Oil Drill Prod Technol 42(2):5 (In Chinese)

Liu B, Hu MM, Zhang B, Li B, Xu B, Huang C, Yu H, Zhang JC, Gu LQ (2023) Influence of abrasive waterjet pre-cutting slit on the performance of shield cutter cutting reinforced concrete. Tunn Undergr Space Technol 142: 105448

Lu GM, Feng XT, Li YH, Zhang XW (2019) The microwave-induced fracturing of hard rock. Rock Mech Rock Eng 52:3017–3032

Lu YY, Tang JR, Ge ZL, Xia BW, Liu Y (2013) Hard rock drilling technique with abrasive water jet assistance. Int J Rock Mech Min Sci 60:47–56

Maeda M, Kushiyama K (2005) Use of compact shield tunneling method in urban underground construction. Tunn Undergr Space Technol 20(2):159–166

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geotech Abstr 31(6):643–659

Ndeda R, Sebusang SEM, Marumo R, Ogur EO (2017) On the role of laser pulses on spallation of granite. Lasers Manuf Mater Process 4:60–75

Pooniwala S (2006) Lasers: the next bit. In: SPE Eastern regional meeting. OnePetro

Ren FS, Fang TC, Cheng XZ (2019) Theoretical modeling and experimental study of rock-breaking depth in particle jet impact drilling process. J Pet Sci Eng 183(1–2):106419

Rui F, Zhao GF (2021) Experimental and numerical investigation of laser-induced rock damage and the implications for laser-assisted rock cutting. Int J Rock Mech Min Sci 139(7):104653

Wang S, Xu Y, Xia KW, Tong TY (2020a) Dynamic fragmentation of microwave irradiated rock. J Rock Mech Geotech Eng 13(2):300–310

Wang YJ, Jiang JY, Darkwa J, Xu ZY, Zheng XF, Zhou GQ (2020b) Experimental study of thermal fracturing of Hot Dry Rock irradiated by moving laser beam: temperature, efficiency and porosity. Renew Energy 160:803–816

Xu BL, Liu SY, Li HS (2022) Drill string’s axial force transfer law in slide directional drilling in underground coal mine. Tunn Undergr Space Technol 130:104701

Xu Y, Yao W, Wang S, Xia KW (2020) Investigation of the heat-treatment effect on rock fragmentation characteristics using the dynamic ball compression test. Rock Mech Rock Eng 53(5):2095–2108

Yang JP, Chen WZ, Yang DS, Yang DS, Tian HM (2016) Estimation of elastic moduli of non-persistent fractured rock masses. Rock Mech Rock Eng 49:1977–1983

Yang SQ, Ranjith PG, Jing HW, Tian WL, Ju Y (2017) An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 65:180–197

Yin TB, Li XB, Cao WZ, Xia KW (2015) Effects of thermal treatment on tensile strength of Laurentian granite using Brazilian test. Rock Mech Rock Eng 48:2213–2223

Zhang Y, Tao LJ, Liu J, Xu Z, Fei G, Lei T, Wang ZQ (2023) Construction techniques and mechanical behavior of newly-built large-span tunnel ultra-short distance up-crossing the existing shield tunnel with oblique angle. Tunn Undergr Space Technol 138:105162

Zhao ZH (2016) Thermal influence on mechanical properties of granite: a microcracking perspective. Rock Mech Rock Eng 49:747–762

Zhou XP, Chen JW (2019) Extended finite element simulation of step-path brittle failure in rock slopes with non-persistent en-echelon joints. Eng Geol 250:65–88

Zhou XP, Zhang T, Qian QH (2021) A two-dimensional ordinary state-based peridynamic model for plastic deformation based on Drucker-Prager criteria with non-associated flow rule. Int J Rock Mech Min Sci 146:104857

Zhou YQ, Sheng Q, Li NN, Fu XD (2020) The influence of strain rate on the energy characteristics and damage evolution of rock materials under dynamic uniaxial compression. Rock Mech Rock Eng 53:3823–3834

Zhu XH, Luo YX, Liu WJ, Hu H, Chen MQ (2022) Numerical electric breakdown model of heterogeneous granite for electro-pulse-boring. Int J Rock Mech Min Sci 154:105128

Acknowledgements

This paper is funded by the National Natural Science Foundation of China (No. 42272311, 52021005), the Key Research and Development Plan of Shandong Province (No. 2020ZLYS01, 2022CXPT016), National Natural Science Youth Fund (No. 52309134), Shandong Province Natural Science Youth Fund (No. ZR2023QE266) and Laser Assisted Intelligent and Efficient Drilling and Tunneling Technology and Equipment (No. 1410121062).

Funding

This paper is funded by the National Natural Science Foundation of China (No. 42272311, 52021005, 52309134), the Key Research and Development Plan of Shandong Province (No. 2020ZLYS01, 2022CXPT016), Natural Science Youth Foundation of Shandong Province (No. ZR2023QE266). No external funding was used.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conficts of interest relevant to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, B., Huang, X., Li, B. et al. The Effect of Laser Irradiation on the Compressive Strength of Granite Under Uniaxial Compression. Rock Mech Rock Eng 57, 1881–1895 (2024). https://doi.org/10.1007/s00603-023-03655-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03655-y