Abstract

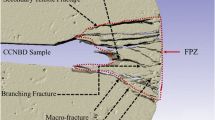

Due to the presence of natural joints and weak interlayer interfaces in the rock mass, the rock mass will be damaged or even deformed to high degree under the action of dynamic loads such as strong seismic activity, resulting in significant engineering safety accidents and casualties. In light of the aforementioned dynamic issues with rock discontinuities, complete rock samples and interface rock samples containing cemented material (gypsum) underwent a series of SHPB impact compressive and splitting tensile tests. To investigate the dynamic properties and change laws of rocks, theoretical analysis, high-speed camera systems, and "binary method" fracture extraction technology were employed. It was concluded that the peak strength of impact tension and impact compression of the samples increased with the increase of strain rate in a power function relationship. The cemented material (gypsum) interface causes stress wave and energy dissipation to be attenuated. When compared to an intact rock sample, the interface causes the number, area, and transmission coefficient of the cracks to decrease, preventing further crack development. However, the initial position and development direction of the crack and the overall stress loading of the sample are not affected. When the energy input is too much, the rock crack gradually changes from peritectic to transgranular, showing that the dissipative energy increases and reaches the peak strength. The findings can serve as a guide and a point of reference for major projects involving joined rock mass and broken rock mass in terms of safety design and operation.

Highlights

-

Peak strength of the rock sample increases as a power function of strain rate.

-

Strain rate does not affect the initial position and development direction of the crack.

-

The interface decreases the number, area, and transmission coefficient of the cracks.

-

Cemented interface causes the stress wave and energy dissipation to be attenuated.

-

Cracks will change from peritectic to transgranular as the input energy is too great.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- SHPB:

-

Split Hopkinson pressure bar

- \(C_{{\text{e}}}\) :

-

Wave velocity of the compressive bar

- \(E_{{\text{e}}}\) :

-

Elastic modulus of the compressive bar

- \(L_{{\text{s}}}\) :

-

Length of the rock sample

- \(A_{{\text{e}}}\) :

-

Cross-sectional area of the compressive bar

- \(A_{{\text{s}}}\) :

-

Cross-sectional area of the rock sample

- \(\varepsilon_{{\text{I}}} (t)\) :

-

Measured strain signals incident waves

- \(\varepsilon_{{\text{R}}} (t)\) :

-

Measured strain signals reflected waves

- \(\varepsilon_{{\text{T}}} (t)\) :

-

Measured strain signals refracted waves

- \(E\) :

-

Tensile modulus (tensile stress plays a leading role when the sample breaks, so the position tensile modulus is defined)

- \(L\) :

-

Sample length (thickness)

- \(P\) :

-

Failure load

- \(D\) :

-

Diameter

- \(\Delta u\) :

-

Deformation

- \(\mu\) :

-

Poisson’s ratio

- \(R\) :

-

Sample radius

- C-3-1:

-

Impact compressive test, 3 m/s and the first rock specimen

- T-3-1:

-

Impact tensile test, 3 m/s and the first rock specimen

- \(W_{{\text{I}}}\) :

-

Energy of the incident wave

- \(W_{{\text{R}}}\) :

-

Energy of the reflected wave

- \(W_{{\text{T}}}\) :

-

Energy of reflected wave

- \(W_{{\text{D}}}\) :

-

Energy lost during specimen failure

- \(E_{0}\) :

-

Initial peak strength

- \(E_{50}\) :

-

The 50% peak strength

References

Bahaaddini M, Hagan PC, Mitra R, Hebblewhite BK (2015) Parametric study of smooth joint parameters on the shear behaviour of rock joints. Rock Mech Rock Eng 48:923–940

Cai M (2002) Rock mechanics and engineering. Science Press, Beijing

Cao P, Liu T, Pu C, Lin H (2015) Crack propagation and coalescence of brittle rock-like specimens with pre-existing cracks in compression. Eng Geol 187:113–121

Cao R, Cao P, Lin H et al (2016) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach. Rock Mech Rock Eng 49:763–783

Chai S, Li J, Li H (2014) Propagation characteristics of cylindrical waves in jointed rock masses. Chin J Rock Mech Eng 33:523–530

Chen P, Lei T (2016) Numerical simulation study of single-hole step blasting based on ALE algorithm. Non-Ferrous Met 68:72–76

Chen W, Lu S, Guo X et al (2009) Research on unloading confining pressure tests and rockburst criterion based on energy theory. Chin J Rock Mech Eng 28(8):1530–1540

Chen P, Kong Y, Yu H (2018) Mesoparameter calibration study of rock uniaxial compression PFC~ (2D) model. Chin J Undergr Space Eng 14:1240–1249

Cui HZ, Tommy YL, Memon SA, Xing F, Shi X (2012) Analytical model for compressive strength, elastic modulus and peak strain of structural lightweight aggregate concrete. Constr Build Mater 36:1036–1043

Fakhimi A, Azhdari P, Kimberley J (2018) Physical and numerical evaluation of rock strength in split Hopkinson pressure bar testing. Comput Geotech 102:1–11

Fan LM, Yan N, Li N (2006) Dynamic response model for thin soft interlayer considering interbedded reflecting waves. Chin J Rock Mech Eng 25(01):88–92

Friedman M, Perkins RD, Green SJ (1970) Observation of brittle-deformation features at the maximum stress of westerly granite and solenhofen limestone. Int J Rock Mech Min 7:297–302

Gong FQ, Li XB (2010) Analytical algorithm for tensile modulus in Brazilian disc splitting test. Chin J Rock Mech Eng 29:881–891

Gong FQ, Li XB, Dong L (2013a) Solving algorithm for the tensile elastic modulus of rock in disc impact splitting test. Chin J Rock Mech Eng 32:705–713

Gong FQ, Lu D, Li XB, Rao Q (2013b) Experimental research of sandstone dynamic strength criterion under different strain rates. Rock Soil Mech 34:2433–2441+2448

Gong FQ, Ye H, Luo Y (2018) The effect of high loading rate on the behaviour and mechanical properties of coal-rock combined body. Shock Vib 2018:1–9

Gong FQ, Yan JY, Luo S, Li XB (2019) Investigation on the linear energy storage and dissipation laws of rock materials under uniaxial compression. Rock Mech Rock Eng 52:4237–4255

Hao Y, Hao H (2013) Dynamic compressive behaviour of spiral steel fibre reinforced concrete in split Hopkinson pressure bar tests. Constr Build Mater 48:521–532

Hokka M, Black J, Tkalich D et al (2016) Effects of strain rate and confining pressure on the compressive behavior of Kuru granite. Int J Impact Eng 91:183–193

Hong L, Li X, Ma C, Yin T, Ye Z, Liao G (2008) Size effect study of rock dynamic strength and its strain rate sensitivity. Chin J Rock Mech Eng 196(03):526–533

Imani M, Nejati HR, Goshtasbi K (2017) Dynamic response and failure mechanism of Brazilian disk specimens at high strain rate. Soil Dyn Earthq Eng 100:261–269

Jiang MX, Yan TJ, Zhang Y, Nie BL (2011) Study on rock breaking mechanism for particle impacting and parameter optimization based on LS-DYNA. Oil Field Equip 40(08):14–18

Ju Y, LiXie YXHP et al (2006) Stress wave propagation and energy dissipation in jointed rocks. Chin J Rock Mech Eng 25(12):2426–2434

Komurlu E, Kesimal A, Demir S (2016) Experimental and numerical analyses on determination of indirect (splitting) tensile strength of cemented paste backfill materials under different loading apparatus. Geomech Eng 10(6):775–791

Lee H, Haimson BC (2011) True triaxial strength, deformability, and brittle failure of granodiorite from the San Andreas Fault Observatory at depth. Int J Rock Mech Min 48(7):1199–1207

Li XB (2014) Rock dynamics fundamentals and applications. Science Press, Beijing

Li J, Li H (2010) Study on one-dimensional dynamic equivalent continuum model of jointed rock mass. Chin J Rock Mech Eng 29:4063–4067

Li XF, Zhang QB, Li HB, Zhao J (2018) Grain-based discrete element method (GB-DEM) modelling of multi-scale fracturing in rocks under dynamic loading. Rock Mech Rock Eng 51:3785–3817

Li JC, Rong LF, Li HB, Hong SN (2019) An SHPB test study on stress wave energy attenuation in jointed rock masses. Rock Mech Rock Eng 52:403–420

Liang H, Li XB, Ma CD, Yin TB et al (2008) Study on size effect of rock dynamic strength and strain rate sensitivity. Chin J Rock Mech Eng 27(3):526–533

Liu T, Li J, Li H, Cai S (2013) Energy analysis of stress waves by nonlinear parallel joints. Chin J Rock Mech Eng 32:1610–1617

Liu H, Deng Z, Wang X, Zhang J, Zhang L (2014) Experimental study of SHPB-like materials for dynamic failure of joint rock mass. Geomechanics 35:659–665

Luo Z, Zhu ZD, Ruan HN, Shi C (2015) Extraction of microcracks in rock images based on heuristic graph searching and application. Comput Geosci 85:22–35

Meng H, Li QM (2013) Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments. Int J Impact Eng 28(05):537–555

Meng QB, Han LJ, Pu H et al (2016) Effect of the size and strain rate on the mechanical behavior of rock specimens. J China Univ Min Sci 45(2):233–243

Nicksiar M, Martin CD (2012) Evaluation of methods for determining crack initiation in compression tests on low-porosity rocks. Rock Mech Rock Eng 45:607–617

Stacey TR (1981) A simple extensile strain criterion for fracture of brittle rock. Int J Rock Mech Min 18:469–474

Vivek P, Frank S, Auriol SPR, Thomas K (2023) Dynamic split tensile strength of basalt, granite, marble and sandstone: strain rate dependency and fragmentation. Rock Mech Rock Eng 56:109–128

Wang W, Li XB, Zhou ZL, Zhang Y (2006) Energy-transmitted rule of various stress waves across open joint . J Cent South Univ 37(2): 376–380

Wesseloo J, Stacey TR (2016) A reconsideration of the extensile strain criterion for fracture and failure of rock. Rock Mech Rock Eng 49:4667–4679

Wu N, Zhang C, Maimaitiyusupu S, Zhu ZD (2019) Investigation on properties of rock joint in compression dynamic test. KSCE J Civ Eng 23:3854–3863

Wu N, Fu J, Zhu ZD, Sun B (2020) Experimental study on the dynamic behavior of the Brazilian disc sample of rock material. Int J Rock Mech Min 130:104326

Xia KW, Yao W (2015) Dynamic rock tests using split Hopkinson (Kolsky) bar system—a review. J Rock Mech Geotech 7:27–59

Xia KW, Yao W, Wu B (2017) Dynamic rock tensile strengths of Laurentian granite: experimental observation and micromechanical model. J Rock Mech Geotech 9:116–124

Xing HZ, Zhang QB, Zhao J (2018) Stress thresholds of crack development and poisson’s ratio of rock material at high strain rate. Rock Mech Rock Eng 51:945–951

Xu Y, Yao W, Xia KW (2020) Numerical study on tensile failures of heterogeneous rocks. J Rock Mech Geotech 12:50–58

Yu Y, Wang TX (2004) Study on relationship between splitting behaviour and elastic modulus of three georges granite. Chin J Rock Mech Eng 23(19):3258–3261

Zhang XM, Ou XF, Gong FQ, Yang JS (2019) Effects of bedding on the dynamic compressive properties of low anisotropy slate. Rock Mech Rock Eng 52:981–990

Zhao J, Li HB (2000) Experimental determination of dynamic tensile properties of a granite. Int J Rock Mech Min 37:861–866

Zhao J, Cai JG, Zhao XB, Song HW (2003) Transmission of elastic P-waves across single fracture with nonlinear normal deformation behavior. Chin J Rock Mech Eng 22(01):9–17

Zhou ZL, Lu JY, Cai X (2020) Static and dynamic tensile behavior of rock-concrete bi-material disc with different interface inclinations. Constr Build Mater 256:119424

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 52209130 and 52108448) and the Fundamental Research Funds for the Central Universities (No. B220202058). The work was also funded by ARC Discovery Project grant DP210100437.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, C., Zhu, Z., Wang, S. et al. Experimental Research on Dynamic Failure of Rock–Cemented Material–Rock Interface Considering Strain Rate Effect. Rock Mech Rock Eng 57, 145–162 (2024). https://doi.org/10.1007/s00603-023-03560-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03560-4