Abstract

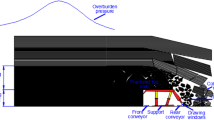

Hard roof’s 3D breaking characteristics is vital for mining pressure control. However, the research concerning a longwall face that employs an innovative roof-cutting technology via a chainsaw arm machine (RCTCAM) is scant. To address this gap, this paper thoroughly analyzes RCTCAM’s core equipment and roof-cutting procedures. Firstly, the thin elastic plate theory and the superposition principle were applied to establish the first and periodic break mechanical models of hard roofs using the RCTCAM. These mechanical models elucidated the distribution laws of the first and third principal bending moments in a hard roof. Following this, based on tensile failure criteria and crack expansion criteria, the study uncovered that the hard roof's first break transitioned from an ‘O–X’ shape to a ‘U–Y’ shape, while its periodic break morphed from a ‘C–ン’ shape to an ‘L–ノ’ shape. This transformation led to a unique phenomenon. The rotation of arc-shaped triangular plates formed during the 'O–X' and ‘C–ン’ -shaped breaks resulted in severe damage to a gob-side roadway. However, a longwall face employing the RCTCAM did not produce such plates, effectively avoiding the associated damage. By implementing the RCTCAM in Workface 8311 of the Yanya Mine in China, the stress peaks of the coal pillars were reduced on average by 22.8%, and the deformation of the roadway decreased by 27.8%. These findings underline the success of the RCTCAM in achieving pressure relief for a gob-side roadway.

Highlights

-

It was given that the theoretical calculation method for deflection, bending moment, and stress of a hard roof with the RCTCAM under the first and periodic breaks.

-

When with the RCTCAM, hard roof’s first break exhibits a transition from an ‘O-X’ shape to an ‘U-Y’ shape, while its periodic break changes from a ‘C-ン’ shape to an ‘L-ノ’ shape.

-

Due to rotation of arc-shaped triangular plates formed in the ‘O-X’ and ‘C-ン’-shaped breaks, a gob-side roadway bear severe damage. However, a longwall face with the RCTCAM has no such plates, thus avoiding damage.

-

With the RCTCAM in Workface 8311 of the Yanya Mine, China, the stress peaks of a gob-side roadway’s coal pillars dropped averagely by 22.8%, indicating that the RCTCAM achieve pressure relief for a gob-side roadway.

Similar content being viewed by others

Data availability

All relevant data are within the paper.

Abbreviations

- \(M_{x}\) :

-

Bending moment along the x axis

- \(M_{y}\) :

-

Bending moment along the y axis

- \(M_{xy}\) :

-

Bending moment along the normal of the xy plane

- D :

-

Plate’s bending stiffness

- E :

-

Elastic modulus

- v :

-

Poisson’s ratio

- \(M_{1}\) :

-

First main bending moment

- \(M_{3}\) :

-

Third main bending moment

- \(\sigma_{1}\) :

-

First principal stress

- \(\sigma_{3}\) :

-

Third principal stress

- h :

-

Thickness of the plate

- \(w_{1}\) ~ \(w_{6}\) :

-

Deflection function of the plate

- \(V_{x}\), \(V_{y}\) :

-

Slopes on edges \(x = 0\) and \(y = 0\)

- \(R\) :

-

Reaction force

- \(M\) :

-

Bending moment

- a, b :

-

Length of plate’s edge

- k :

-

Constant

References

Bai Q, Tu S, Wang F, Zhang C (2017) Field and numerical investigations of gateroad system failure induced by hard roofs in a longwall top coal caving face. Int J Coal Geol 173:176–199. https://doi.org/10.1016/j.coal.2017.02.015

Bernar II, Opanasovich VK (1984) Bending of a plate with a thin-walled elastic inclusion along a circular arc. Sov Appl Mech 20:730–737. https://doi.org/10.1007/Bf00889454

Cao A, Zhu L, Li F, Dou L, Zhao Y, Zhang Z (2014) Characteristics of T-type overburden structure and tremor activity in isolated face mining under thick-hard strata. J China Coal Soc 39:328–335

Chen C, Yang R, Xu P, Ding C (2022) Experimental study on the interaction between oblique incident blast stress wave and static crack by dynamic photoelasticity. Opt Lasers in Eng 148:106764. https://doi.org/10.1016/j.optlaseng.2021.106764

Ding C, Yang R, Chen C, Zhu X, Feng C, Xie Q (2022) Space-time effect of blasting stress wave and blasting gas on rock fracture based on a cavity charge structure. Int J Rock Mech Min Sci 160:105238. https://doi.org/10.1016/j.ijrmms.2022.105238

Dixon AC (1926) The functions involved in the theory of a thin elastic rectangular plate, clamped at the edges, and certain integral equations satisfied by such functions. P Lond Math Soc 25:417–450

Gao F, Stead D, Kang H (2014) Numerical simulation of squeezing failure in a coal mine roadway due to mining-induced stresses. Rock Mech Rock Eng 48:1635–1645. https://doi.org/10.1007/s00603-014-0653-2

Grilitskii DV, Opanasovich VK, Dragan MS (1984) Bending of a plate with a system of thin elastic inclusions. Sov Appl Mech 20:848–852. https://doi.org/10.1007/Bf00888490

Guo S, Tai Y, Wang Z-W, Shi B-W, Yang K (2021) Fracture characteristics of basic roof and mechanism of strata behavior in a pillarless working face. J Geophys Eng 18:875–889. https://doi.org/10.1093/jge/gxab059

Han C-l (2015) Pressure relief and structure stability mechanism of hard roof for gob-side entry retaining. J Central South Univ 22:4445–4455. https://doi.org/10.1007/s11771-015-2992-x

Huang BX, Chen SL, Zhao XL (2017) Hydraulic fracturing stress transfer methods to control the strong strata behaviours in gob-side gateroads of longwall mines. Arab J Geosci. https://doi.org/10.1007/s12517-017-3024-y

Huang B, Liu J, Zhang Q (2018) The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry. Int J Rock Mech Min Sci 103:1–11. https://doi.org/10.1016/j.ijrmms.2018.01.013

Jiang J, Zhang P, Nie L, Li H, Xu L, Wang W (2014) Fracturing and dynamic response of high and thick stratas of hard rocks. Chin J Rock Mech Eng 33:1366–1374

Jiang H, Cao S, Zhang Y, Wang C (2016) Study on the first failure and caving mechanism of key strata of shallow coal seam. J Min Saf Eng 33:860–866

Kayumov RA, Tazyukov BF (2001) Stability of a thin curved elastic plate loaded by the transverse force Izv Vuz Aviats Tekh 12–15

Kong DZ, Lou YH, Zheng SS, Pu SJ (2021) The Characteristics of roof breaking and the law of ground pressure behavior in fully mechanized top-coal caving face with large mining height. Geotech Geol Eng 39:285–297. https://doi.org/10.1007/s10706-020-01492-2

Li R, Zhong Y, Li M (2013) Analytic bending solutions of free rectangular thin plates resting on elastic foundations by a new symplectic superposition method. Proc R Soc Math Phy 469:20120681

Li X, Ju M, Yao Q, Zhou J, Chong Z (2015) Numerical investigation of the effect of the location of critical rock block fracture on crack evolution in a gob-side filling wall. Rock Mech Rock Eng 49:1041–1058. https://doi.org/10.1007/s00603-015-0783-1

Li J, Liu D, He M, Guo Y, Wang H (2023) Experimental investigation of true triaxial unloading rockburst precursors based on critical slowing-down theory. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-023-03092-9

Lin SM, Teng MJ (2015) The analysis and model formulation of a coupled micro-probe and elastic thin plate subjected to electrostatic force. Int J Mech Sci 103:224–234. https://doi.org/10.1016/j.ijmecsci.2015.08.010

Liu X, Tao TJ, Tian XC, Lou QX, Xie CJ (2022) Layout method and numerical simulation study of reduced-hole blasting in large-section tunnels. Front Earth Sci-Switz. https://doi.org/10.3389/feart.2022.976419

Marchant MJ, Snell MB (1982) Determination of the flexural stiffness of thin plates from small deflection measurements using optical holography. J Strain Anal Eng 17:53–61. https://doi.org/10.1243/03093247v171053

Minggao Q, Deren Z, Zuotang W (1986) The fracture types of main roof and their effects on roof pressure in coal face International Journal of. Min Sci Technol 15:9–18

Pu H, Huang Y-G, Chen R-H (2011) Mechanical analysis for X–O type fracture morphology of stope roof. J China Univ Min Technol 40:835–840

Rathore SS, Bhandari S (2007) Controlled fracture growth by blasting while protecting damages to remaining rock. Rock Mech Rock Eng 40:317–326. https://doi.org/10.1007/s00603-005-0080-5

Ren MF, Cong J, Wang B, Guo XL (2017) Extended multiscale finite element method for small-deflection analysis of thin composite plates with aperiodic microstructure characteristics. Compos Struct 160:422–434. https://doi.org/10.1016/j.compstruct.2016.10.073

Ren F, Zhu C, He M, Shang J, Feng G, Bai J (2022) Characteristics and precursor of static and dynamic triggered rockburst: insight from multifractal. Rock Mech Rock Eng 56:1945–1967. https://doi.org/10.1007/s00603-022-03173-3

Roche V, van Der Baan M, Preisig G (2018) A study of 3D modeling of hydraulic fracturing and stress perturbations during fluid injection. J Pet Sci Eng 170:829–843. https://doi.org/10.1016/j.petrol.2018.06.037

Saiang D (2010) Stability analysis of the blast-induced damage zone by continuum and coupled continuum-discontinuum methods. Eng Geol 116:1–11. https://doi.org/10.1016/j.enggeo.2009.07.011

Shakib JT, Ghaderi A, Shahri AA (2012) Analysis of hydraulic fracturing in fractured reservoir: interaction between hydraulic fracture and natural fractures life science. J-Acta Zhengzhou Univ Overseas Edition 9:1854–1862

Shufrin I, Rabinovitch O, Eisenberger M (2009) Elastic nonlinear stability analysis of thin rectangular plates through a semi-analytical approach. Int J Solids Struct 46:2075–2092. https://doi.org/10.1016/j.ijsolstr.2008.06.022

Wang J, Zhang J, Gao X, Wen J, Gu Y (2015) Fracture mode and evolution of main roof stratum above longwall fully mechanized top coal caving in steeply inclined thick coal seam (I)-Initial fracture. J China Coal Soc 40:1353–1360

Wu HJ, Gong M, Yang RS, Wu XD, Liu XY (2023) Double-face intelligent hole position planning method for precision blasting in roadways using a computer-controlled Drill Jumbo. Int J Min Met Mater. https://doi.org/10.1007/s12613-022-2575-4

Xia X, Li HB, Li JC, Liu B, Yu C (2013) A case study on rock damage prediction and control method for underground tunnels subjected to adjacent excavation blasting. Tunn Undergr Space Technol 35:1–7. https://doi.org/10.1016/j.tust.2012.11.010

Xie S-R, Chen D-D, Sun Y-D, Gao M-M, Sun Y-J, Shi W (2016) Analysis on thin plate model of basic roof at elastic foundation boundary(I): first breaking. J China Coal Soc 41:1360–1368

Xu JH, Li GC, Gomah ME, Chen BA, Sun CL, Rong HY, Zhang Q (2023) Overlying main roof breaking characteristic and its effect on the stability of gob-side entry. Geomech Geophys Geo 9:26

Yan GW, Yao S, Li YL, Zhou WX (2023) Topological optimization of thin elastic metamaterial plates for ultrawide flexural vibration bandgaps. Int J Mech Sci 242:108014

Zhang ZY, Zhang N, Shimada H, Sasaoka T, Wahyudi S (2017) Optimization of hard roof structure over retained goaf-side gateroad by pre-split blasting technology. Int J Rock Mech Min Sci 100:330–337. https://doi.org/10.1016/j.ijrmms.2017.04.007

Zhang XY, Hu JZ, Xue HJ, Mao WB, Gao YB, Yang J, He MC (2020) Innovative approach based on roof cutting by energy-gathering blasting for protecting roadways in coal mines. Tunn Undergr Space Technol 99:103387. https://doi.org/10.1016/j.tust.2020.103387

Zhu AI, Zhang Y, AI MI, Xu JQ, (2017) Reinforcement mechanism of slopes with yielding anchor cables based on numerical simulation of FLAC3D. Chin J Geotech Eng 39:713–719

Zuo J, Yang R, Gong M, Ma X, Wang Y (2022) Fracture characteristics of iron ore under uncoupled blast loading. Int J Min Sci Technol 32:657–667. https://doi.org/10.1016/j.ijmst.2022.03.008

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52204127), the Autonomous General Projects of State Key Laboratory of Coal Mine Disaster Dynamics and Control (2011DA105287-MS202209), the China Postdoctoral Science Foundation (2021M700595), the Chongqing Natural Sciences Foundation (CSTB2022NSCQ-MSX1262), and the Lump Sum System Project of Chongqing Talent Plan (CSTC2022YCJH -BGZXM0005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tai, Y., Kuang, T., Yu, B. et al. Hard Roof’s 3D Breaking Characteristics for Longwall Faces Mined via Roof-Cutting Technology with a Chainsaw Arm Machine. Rock Mech Rock Eng 57, 429–449 (2024). https://doi.org/10.1007/s00603-023-03550-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03550-6