Abstract

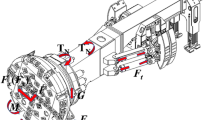

Dynamic information about the cutting force of each cutter, such as peak and frequency of normal force, is essential to address the deformation and vibration of the cutterhead during tunnel construction using tunnel boring machines (TBM). Existing theoretical/empirical models of cutting forces and models of cutterhead deformation and vibration often use static forces for simplified analysis. It will have an impact on cutterhead design and performance analysis. In this study, a dynamic cutting force model is established based on the cavity expansion model and discretization method. This model calculates the period of the cutting force from cutter size, operation parameters and rock strength. Then, it is applied to the equation of motion of the cutterhead as the external load. The natural frequency, mode shape, deformation, and forced vibration of the cutterhead are analyzed. Finally, the cutterhead vibration response was calculated under typical geological conditions and operating parameters. The results show that increased installation radius of cutter, rotational speed and penetration of cutterhead increase the volume of rock extruded by the cutter per unit of time. The core boundary velocity and the frequency of cutting forces are also increased. Furthermore, the dynamic response of the cutterhead is significantly correlated with the geological conditions and operation parameters. Using greater advance rate and rotational speeds on stronger rocks results in most severe vibration of the cutterhead. These results demonstrate that the model provides theoretical support for cutterhead vibration analysis.

Highlights

-

The series of tests performed on the full-scale rotary cutting machine with a synchronous monitoring system for the force of the cutter and the vibration of the cutterhead reveals the significant influence of the rock and operating parameters on cutting force and cutterhead vibration.

-

The proposed novel dynamic cutting force model with rock and operation parameters is proved useful in analyze dynamic information of cutting force.

-

The presented detailed mechanistic analysis of cutterhead vibration applying dynamic forces for TBM tunneling identifies the key parameters controlling system vibration and permits transferring theoretical results to in situ applications.

Similar content being viewed by others

Data Availability

The data used in this research has been supplied in tables and figures.

References

Alehossein H, Detournay E, Huang H (2000) An analytical model for the indentation of rocks by blunt tools. Rock Mech Rock Eng 33(4):267–284

Bauer HF, Eidel W (2007) Transverse vibration and stability of spinning circular plates of constant thickness and different boundary conditions. J Sound Vib 300(3):877–895

Chen LH, Labuz JF (2006) Indentation of rock by wedge-shaped tools. Int J Rock Mech Min Sci 43(7):1023–1033

Cho J-W, Jeon S, Jeong H-Y, Chang S-H (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54

Entacher M, Winter G, Bumberger T, Decker K, Godor I, Galler R (2012) Cutter force measurement on tunnel boring machines—system design. Tunn Undergr Space Technol 31:97–106

Entacher M, Winter G, Galler R (2013) Cutter force measurement on tunnel boring machines—implementation at Koralm tunnel. Tunn Undergr Space Technol 38:487–496

Evans I, Pomeroy CD (1966) The strength, fracture and workability of Coal. In: Pergamon process. London

Geng Q, He F, Ma M, Liu X, Wang X, Zhang Z, Ye M (2022) Application of full-scale experimental cutterhead system to study penetration performance of tunnel boring machines (TBMs). Rock Mech Rock Eng 55:4673–4696

Han M, Chen K, Cai Z, Qu C (2016) Parametric modeling method for finite element analysis of TBM cutterhead. Mech Sci Technol Aerosp Eng 35(10):1489–1493

Han MD, Cai ZX, Qu CY, Jin LS (2017) Dynamic numerical simulation of cutterhead loads in TBM tunnelling. Tunn Undergr Space Technol 70:286–298

Huang H, Damjanac B, Detournay E (1998) Normal wedge indentation in rocks with lateral confinement. Rock Mech Rock Eng 31(2):81–94

Huang X, Liu Q, Chen L, Pan Y, Liu B, Kang Y, Liu X (2018) Cutting force measurement and analyses of shell cutters on a mixshield tunnelling machine. Tunn Undergr Space Technol 82:325–345

Huo J, Zhang Z, Meng Z, Li J, Wu H, Jia L (2021) Dynamic analysis and experimental study of a Tunnel boring Machine testbed under multiple conditions. Eng Fail Anal 127:105557

Lamb H, Southwell RV (1921) The vibrations of a spinning disk. Proc R Soc Edinb Sect A-Math 99(699):272–280

Liu M-B, Liao S-M, Men Y-Q, Xing H-T, Liu H, Sun L-Y (2022) Field monitoring of TBM vibration during excavating changing stratum: patterns and ground identification. Rock Mech Rock Eng 55(3):1481–1498

Pan Y, Liu Q, Peng X, Kong X, Liu J, Zhang X (2018) Full-scale rotary cutting test to study the influence of disc cutter installment radius on rock cutting forces. Rock Mech Rock Eng 51:2223–2236

Pan Y, Liu Q, Peng X, Liu Q, Liu J, Huang X, Cui X, Cai T (2019) Full-scale linear cutting tests to propose some empirical formulas for TBM disc cutter performance prediction. Rock Mech Rock Eng 52:4763–4783

Peng X, Liu Q, Pan Y, Lei G, Wei L, Luo C (2018) Study on the influence of different control modes on tbm disc cutter performance by rotary cutting tests. Rock Mech Rock Eng 51:961–967

Qi G, Zhengying W, Fei H, Hao M (2015) Comparison of the mechanical performance between two-stage and flat-face cutter head for the rock tunnel boring machine (TBM). J Mech Sci Technol 29(5):2047–2058

Rostami J (2013) Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters. Int J Rock Mech Min Sci 57:172–186

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstracts 12(12):361–366

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci Geomech Abstracts 22(3):153–161

Snowdon RA, Ryley MD, Temporal J (1982) A study of disc cutting in selected British rocks. Int J Rock Mechc Min Sci Geomech Abstracts 19(3):107–121

Sun H, Gao Y, Zhu G, Xu F, Zheng X (2023) Theoretical and experimental study of tunnel boring machine dynamic cutting force. Rock Soil Mech 44(6):1–14

Wang X, Zhu H, Zhu M, Zhang L, Ju JW (2021) An integrated parameter prediction framework for intelligent TBM excavation in hard rock. Tunn Undergr Space Technol 118:104196

Wu F, Gong Q, Li Z, Qiu H, Jin C, Huang L, Yin L (2021) Development and application of cutterhead vibration monitoring system for TBM tunnelling. Int J Rock Mech Min Sci 54:1731–1753

Xia Y, Guo B, Tan Q, Zhang X, Lan H, Ji Z (2018) Comparisons between experimental and semi-theoretical cutting forces of CCS disc cutters. Rock Mech Rock Eng 51(5):1583–1597

Xu H, Geng Q, Sun Z, Qi Z (2021) Full-scale granite cutting experiments using tunnel boring machine disc cutters at different free-face conditions. Tunn Undergr Space Technol 108:103719

Xue Y, Zhou J, Liu C, Shadabfar M, Zhang J (2021) Rock fragmentation induced by a TBM disc-cutter considering the effects of joints: a numerical simulation by DEM. Comput Geotech 136:104230

Yang H, Renner J, Brackmann L, Röttger A (2022) Normal indentation of rock specimens with a blunt tool: role of specimen size and indenter geometry. Rock Mech Rock Eng 55(4):2027–2047

Zare S, Bruland A (2013) Applications of NTNU/SINTEF drillability indices in hard rock tunneling. Rock Mech Rock Eng 46:179–187

Zhu H, Yan J, Liang W (2019) Challenges and development prospects of ultra-long and ultra-deep mountain tunnels. Engineering 5(3):384–392

Acknowledgements

This work was financially supported by National Key R&D Program of China (Grant No. 2021YFB2600800), National Natural Science Foundation of China (Grant No. 51978425), the Natural Science Foundation of Hebei Province (Grant No. E2021210032), and Hebei Provincial Central Guidance Local Science and Technology Development Project (Grant No. 226Z5405G). The authors also would like to thank the State Key Laboratory of Shield Machine and Boring Technology for providing the full-scale rotary cutting machine.

Author information

Authors and Affiliations

Contributions

HS designed the study, conducted the tests, and wrote the paper; YG participated in the design of this study and tests.

Corresponding author

Ethics declarations

Conflict of interest

We have no competing interests.

Consent for Publication

All authors gave final approval for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Hk., Gao, Y. Dynamic Cutting Force Model and Vibration Analysis of the Cutterhead in TBM. Rock Mech Rock Eng 56, 7883–7903 (2023). https://doi.org/10.1007/s00603-023-03470-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03470-5