Abstract

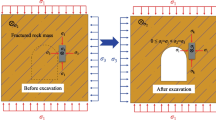

The progressive brittle failure of high-stress hard surrounding rock masses caused by layered excavation severely threatens the stability of large underground caverns. We summarize the stress path in the potential failure zone of the Shuangjiangkou underground powerhouse during layered excavation, and then design the multistep unloading confining pressure test and the cyclic loading–unloading test with multistep unloading confining pressure. The deformation, strength, acoustic emission, and failure characteristics of granite, as well as the evolution of critical stress thresholds and mechanical parameters are analyzed based on experimental results under different stress paths. The peak strength of the rock significantly depends on the stress path and the amount of unloading confining pressure. The rock failure process under multistep unloading confining pressure is divided into stable and unstable crack growth stages, with the failure mode shifting from tensile cracks to mixed tensile–shear cracks. The evolution modes of critical stress thresholds, cohesion, and internal friction angle with amount of unloading confining pressure differ significantly from that with the equal plastic strain. The former is nearly linear, while the latter is exponentially nonlinear. The evolution of the deformation modulus, cohesion, and internal friction angle confirms the rationality of the cohesion-weakening–friction-strengthening model with degraded deformation modulus for the stability analysis of surrounding rock masses under layered excavation. The experimental methods for obtaining the evolution of rock mechanical parameters using a single specimen under unloading confining pressure are also discussed. The results imply that the layered excavation-induced nonlinear deterioration of the deformation modulus and strength parameters of high-stress hard surrounding rock masses should be considered in the stability analysis of large underground caverns. Further, the timely compensation of the excavation-induced confining pressure loss is critical to ensure the stability of high-stress hard surrounding rock masses under layered excavation.

Highlights

-

A stress path was designed to reflect the stress evolution characteristics for rock masses of the large underground cavern under layered excavation;

-

The deformation, strength, acoustic emission, and failure characteristics of granite under the layered excavation stress path were analyzed;

-

The evolution of rock mechanical parameters with unloading confining pressure and the equivalent plastic strain were obtained;

-

An experimental method for obtaining the evolution of rock mechanical parameters using a single specimen under unloading confining pressure was discussed.

Similar content being viewed by others

Data Availability

Data will be made available on request.

Abbreviations

- MSUCPT:

-

Multistep unloading confining pressure test

- CLUT-MSUCP:

-

Cyclic loading–unloading with multistep unloading confining pressures

- IASDCPT:

-

Increasing axial stress and decreasing confining pressure test

- MASDCPT:

-

Maintaining axial stress and decreasing confining pressure test

- CLUT-CCP:

-

Cyclic loading–unloading test with the constant confining pressure

- CLUT-MSLCP:

-

Cyclic loading–unloading test with multistep loading confining pressure

- CTCT:

-

Conventional triaxial compression test

- AE:

-

Acoustic emission

- \(\sigma_{1}^{{}}\) :

-

Maximum principal stress

- \(\sigma_{1}^{0}\) :

-

Initial axial stress of unloading test

- \(\sigma_{3}^{0}\) :

-

Initial confining pressure

- \(\Delta \sigma_{3}^{{}}\) :

-

Amount of unloading confining pressure

- CI :

-

Crack initiation stress threshold

- \(k_{{{\text{cd}}}}^{{}}\) :

-

Slope of fitting line for CD vs \(\sigma_{3}^{0}\)

- \(\varepsilon_{1}^{{}}\) :

-

Axial strain

- \(\varepsilon_{{\text{v}}}^{{}}\) :

-

Volumetric strain

- \(\varepsilon_{{}}^{{\text{p}}}\) :

-

Plastic strain

- \(\varepsilon_{3}^{{\text{e}}}\) :

-

Elastic lateral strain

- \(\varepsilon_{1}^{{\text{p}}}\) :

-

Plastic axial strain

- \(\varepsilon_{{\text{v}}}^{{\text{p}}}\) :

-

Plastic volumetric strain

- \(E_{{\text{u}}}\) :

-

Unloading modulus

- \(c_{{}}^{{}}\) :

-

Cohesion

- \(\sigma_{3}^{{}}\) :

-

Minimum principal stress

- \(\sigma_{1}^{{\text{f}}}\) :

-

Axial stress at failure

- \(\sigma_{3}^{{\text{f}}}\) :

-

Confining pressure at failure

- \(\Delta \sigma_{3}^{0}\) :

-

Amount of single-step unloading confining pressure

- CD :

-

Crack damage stress threshold

- \(\varepsilon_{1}^{{\text{f}}}\) :

-

Axial strain at failure

- \(\varepsilon_{3}^{{}}\) :

-

Lateral strain

- \(\varepsilon_{{}}^{{\text{e}}}\) :

-

Elastic strain

- \(\varepsilon_{1}^{{\text{e}}}\) :

-

Elastic axial strain

- \(\varepsilon_{{\text{v}}}^{{\text{e}}}\) :

-

Elastic volumetric strain

- \(\varepsilon_{3}^{{\text{p}}}\) :

-

Plastic lateral strain

- \(\varepsilon_{{\text{p}}}^{{}}\) :

-

Equivalent plastic strain

- \(\mu_{{\text{u}}}\) :

-

Apparent Poisson’s ratio

- \(\varphi\) :

-

Internal friction angle

References

Aldandooh MAA, Bunnori NM (2013) Crack classification in reinforced concrete beams with varying thicknesses by mean of acoustic emission signal features. Constr Build Mater 45:282–288. https://doi.org/10.1016/j.conbuildmat.2013.03.090

Barton N, Pandey SK (2011) Numerical modeling of two stopping methods in two Indian mines using degradation of c and mobilization of φ based on Q-parameters. Int J Rock Mech Min Sci 48:1095–1112. https://doi.org/10.1016/j.ijrmms.2011.07.002

Cantieni L, Anagnostou G, Hug R (2011) Interpretation of core extrusion measurements when tunneling through squeezing ground. Rock Mech Rock Eng 44:641–670. https://doi.org/10.1007/s00603-011-0170-5

Chen Y, Zuo J, Li Z, Dou R (2020) Experimental investigation on the crack propagation behaviors of sandstone under different loading and unloading conditions. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2020.104310

Dong L, Yang L, Chen Y (2022) Acoustic emission location accuracy and spatial evolution characteristics of granite fracture in complex stress conditions. Rock Mech Rock Eng 2022:1–18. https://doi.org/10.1007/s00603-022-03124-y

Duan K, Ji Y, Wu W, Kwok CY (2019) Unloading-induced failure of brittle rock and implications for excavation-induced strain burst. Tunn Undergr Sp Tech 84:495–506. https://doi.org/10.1016/j.tust.2018.11.012

Eberhardt E, Stead D, Stimpson B (1999) Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int J Rock Mech Min Sci 36:361–380. https://doi.org/10.1016/s0148-9062(99)00019-4

Feng XT, Xu H, Yang CX, Zhang XW, Gao YH (2020) Influence of loading and unloading stress paths on the deformation and failure features of Jinping marble under true triaxial compression. Rock Mech Rock Eng 53:3287–3301. https://doi.org/10.1007/s00603-020-02104-4

Goodman RE (1963) Subaudible noise during compression of rock. Geo Soc Am Bull 74:487–490

Hu L, Feng XT, Xiao YX, Feng GL, Li SJ, Pan PZ, Yao ZB (2019) Characteristics of the micro seismicity resulting from the construction of a deeply-buried shaft. Tunn Undergr Sp Tech 85:114–127. https://doi.org/10.1016/j.tust.2018.12.016

Jiang Q, Su G, Feng XT, Chen G, Zhang M-z, Liu C (2019) Excavation optimization and stability analysis for large underground caverns under high geostress: a case study of the chinese laxiwa project. Rock Mech Rock Eng 52:895–915. https://doi.org/10.1007/s00603-018-1605-z

Jiang Q, Zhang M, Yan F, Su G, Feng X, Xu D, Feng G (2021) Effect of initial minimum principal stress and unloading rate on the spalling and rock burst of marble: a true triaxial experiment investigation. Bull Eng Geol Environ 80:1617–1634. https://doi.org/10.1007/s10064-020-01995-5

Li S, Feng XT, Li Z, Chen B, Zhang C, Zhou H (2012) In situ monitoring of rock burst nucleation and evolution in the deeply buried tunnels of Jinping II hydropower station. Eng Geol 137:85–96. https://doi.org/10.1016/j.enggeo.2012.03.010

Li D, Sun Z, Xie T, Li X, Ranjith PG (2017) Energy evolution characteristics of hard rock during triaxial failure with different loading and unloading paths. Eng Geol 228:270–281. https://doi.org/10.1016/j.enggeo.2017.08.006

Liu G, Feng XT, Jiang Q, Yao Z, Li S (2017) In situ observation of spalling process of intact rock mass at large cavern excavation. Eng Geol 226:52–69. https://doi.org/10.1016/j.enggeo.2017.05.012

Martin CD, Chandler NA (1994) The progressive fracture of Lac Du Bonnet granite. Int J Rock Mech Min Sci Geomechanics Abstracts 31:643–659. https://doi.org/10.1016/0148-9062(94)90005-1

Nicksiar M, Martin CD (2012) Evaluation of methods for determining crack initiation in compression tests on low-porosity rocks. Rock Mech Rock Eng 45:607–617. https://doi.org/10.1007/s00603-012-0221-6

Peng K, Zhou J, Zou Q, Yan F (2019) Deformation characteristics of sandstones during cyclic loading and unloading with varying lower limits of stress under different confining pressures. Int J Fatigue 127:82–100. https://doi.org/10.1016/j.ijfatigue.2019.06.007

Qian QH, Zhou XP (2018) Failure behaviors and rock deformation during excavation of underground cavern group for Jinping I Hydropower Station. Rock Mech Rock Eng 51:2639–2651. https://doi.org/10.1007/s00603-018-1518-x

Qiu SL, Feng XT, Xiao JQ, Zhang CQ (2014) An experimental study on the pre-peak unloading damage evolution of marble. Rock Mech Rock Eng 47:401–419. https://doi.org/10.1007/s00603-013-0394-7

Ranjith PG, Zhao J, Ju M, De Silva RVS, Rathnaweera TD, Bandara AKMS (2017) Opportunities and challenges in deep mining: a brief review. ENGINEERING-PRC 3:546–551. https://doi.org/10.1016/J.ENG.2017.04.024

Renani HR, Martin CD (2018) Cohesion degradation and friction mobilization in brittle failure of rocks. Int J Rock Mech Min Sci 106:1–13. https://doi.org/10.1016/j.ijrmms.2018.04.003

Sang GJ, Liu SM, Elsworth D (2020) Quantifying fatigue-damage and failure-precursors using ultrasonic coda wave interferometry. Int J Rock Mech Min Sci. https://doi.org/10.1016/j.ijrmms.2020.104366

Shahidan S, Pulin R, Bunnori NM, Holford KM (2013) Damage classification in reinforced concrete beam by acoustic emission signal analysis. Constr Build Mater 45:78–86. https://doi.org/10.1016/j.conbuildmat.2013.03.095

Wang J, Chen L, Su R, Zhao XG (2018) The beishan underground research laboratory for geological disposal of high-level radioactive waste in China: planning, site selection, site characterization and in situ tests. J Rock Mech Geotech Eng 10:411–435. https://doi.org/10.1016/j.jrmge.2018.03.002

Wang Y, Feng WK, Hu RL, Li CH (2021) Fracture evolution and energy characteristics during marble failure under triaxial fatigue cyclic and confining pressure unloading (FC-CPU) conditions. Rock Mech Rock Eng 54:799–818. https://doi.org/10.1007/s00603-020-02299-6

Xu NW, Li TB, Dai F, Zhang R, Tang CA, Tang LX (2016) Microseismic monitoring of strainburst activities in deep tunnels at the jinping II hydropower station, China. Rock Mech Rock Eng 49:981–1000. https://doi.org/10.1007/s00603-015-0784-0

Xu H, Feng XT, Yang C, Zhang X, Zhou Y, Wang Z (2019) Influence of initial stresses and unloading rates on the deformation and failure mechanism of Jinping marble under true triaxial compression. Int J Rock Mech Min Sci 117:90–104. https://doi.org/10.1016/j.ijrmms.2019.03.013

Xu D, Huang X, Jiang Q, Li S, Zheng H, Qiu S, Xu H, Li Y, Li Z, Ma X (2021) Estimation of the three-dimensional in situ stress field around a large deep underground cavern group near a valley. J Rock Mech Geotech Eng 13:529–544. https://doi.org/10.1016/j.jrmge.2020.11.007

Xu D-P, Huang X, Li S-J, Xu H-S, Qiu S-L, Zheng H, Jiang Q (2022) Predicting the excavation damaged zone within brittle surrounding rock masses of deep underground caverns using a comprehensive approach integrating in situ measurements and numerical analysis. Geosci Front. https://doi.org/10.1016/j.gsf.2021.101273

Yang S-Q, Tian W-L, Ranjith PG (2017) Experimental investigation on deformation failure characteristics of crystalline marble under triaxial cyclic loading. Rock Mech Rock Eng 50:2871–2889. https://doi.org/10.1007/s00603-017-1262-7

Zhao XG, Wang J, Cai M, Cheng C, Ma LK, Su R, Zhao F, Li DJ (2014) Influence of unloading rate on the strain burst characteristics of Beishan granite under true-triaxial unloading conditions. Rock Mech Rock Eng 47:467–483. https://doi.org/10.1007/s00603-013-0443-2

Acknowledgements

This research was funded by the National Natural Science Foundation of China (Grant No. 51979268). In particular, the authors also wish to thank Prof. Hua Zhang from State Key Laboratory of Geomechanics and Geotechnical Engineering, who gave support and assistance during the triaxial unloading tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known conflict financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xia, Y., Xu, D., Qiu, S. et al. Experimental Study on Mechanical Properties of Deeply Buried Granite During Layered Excavation of Large Underground Caverns. Rock Mech Rock Eng 56, 4757–4778 (2023). https://doi.org/10.1007/s00603-023-03304-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03304-4