Abstract

The engineering behaviour of rock is strongly associated with the anisotropy, which exists at different scales for construction safety and evaluation of rock properties. It is also well known that the anisotropy of the drilling mechanical characteristics in the rock cutting process has an essential effect on the drilling efficiency and cost. For this purpose, an effort was made to characterize the anisotropy of the drilling mechanical characteristics of rocks in the rock drilling process. The drilling strength and specific energy at the cutting point are considered to characterize the drilling process in three different directions according to the drilling response model. A drilling characteristic-based index is proposed to evaluate the anisotropy of rock. Drilling tests were conducted in three directions for six types of rock to study the anisotropy variation along the borehole depth. The anisotropy evolution result along the borehole suggested that this critical point is identified as the cutting point, dividing the drilling process into two stages of cutting and frictional contact. The cutting point also shows anisotropic features. The anisotropic ranking of tested rocks was obtained. Based on how the drilling parameters depend on the unconfined compressive strength, the reliability of the proposed anisotropy index is examined by comparison with the strength anisotropy index. The comparative result demonstrates that the proposed method can provide a reliable determination for rock anisotropy by using the drilling strength. The work performed in this paper provides a very useful approach for evaluating the anisotropy of rock and provides a good understanding of the drilling mechanical characteristics in rock drilling.

Highlights

-

The anisotropy of the drilling mechanical characteristics of rocks is characterized in the rock drilling process.

-

The drilling strength and specific energy at the cutting point are considered to characterize the drilling process in three different directions.

-

A drilling characteristic-based index is proposed to evaluate the anisotropy of rock.

-

Drilling tests are conducted in three directions for six types of rock to study the anisotropy variation along the borehole depth.

Similar content being viewed by others

Data availability

The data that support the finding of this study are available form the corresponding author upon reasonable request.

Abbreviations

- R :

-

The radius of the drill bit

- ρ :

-

The ratio of the inner and outer radii of the drill bit

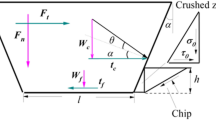

- F n :

-

Thrust force

- F t :

-

Tangential torque force

- W :

-

Scaled contact stress

- t :

-

Tangential stress

- h :

-

The depth per rotation

- W f :

-

The friction components of W

- W c :

-

The cutting components of W

- t f :

-

The friction components of t

- t c :

-

The cutting components of t

- σ0 :

-

Normal stress at the crushed zone

- τ0 :

-

Shear stress at the crushed zone

- φ ’ :

-

Friction angle at the crushed zone

- E :

-

Specific energy

- S :

-

Drilling strength

- α :

-

Rake angle

- θ :

-

Contact angle between the rock and bit

- \({\overline{{K}}}\) :

-

The average value of the drilling strength

References

Bingham MG (1964) How rock properties are related to drilling. Oil Gas J 62(50):94–101

Bobet A, Fakhimi A, Johnson S, Morris J, Tonon F, Yeung R (2009) Numerical models in discontinuous media: review of advances for rock mechanics applications. J Geotech Geoenviron (ASCE) 135(11):1547–1561

Chiaia B, Borri-Brunetto M, Carpinteri A (2013) Mechanical modelling of thmechanics of core drilling in geomaterials. Mach Sci Technol 17:1–25

Dagrain F (2006) Study of rock cutting mechanisms with knives uses approach of friction mechanisms under the knives by the concept of the third body. Ph.D Thesis. Faculte Polytechnique de Mons, 2006.

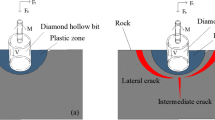

Detournay E, Defourny P (1992) A phenomenological model of the drilling action of drag bits. Int J Rock Mech Min 29:13–23

Detournay E, Hakobyan Y (2022) Hydraulic fracturing of weak rock during waterflooding. Int J Numer Anal Met 46(2):416–435

Richard T, Dagrain F, Detournay E (2008) Determination of rock strength properties from scratching tests. Int J Rock Mech Min. 2008, in preparation.

Fereidooni D, Khanlari GR, Heidari M, Sepahigero AA, Kolahi-Azar AP (2016) Assessment of inherent anisotropy and confining pressure influences on mechanical behaviour of anisotropic foliated rocks under triaxial compression. Rock Mech Rock Eng 49(6):2155–2163

Fjaer E, Holt RM, Horsru P, Raaen AM (2008) Petroleum related rock mechanics. Elsevier, Oxford

Franca LFP, Mostofi M, Richard T (2015) Interface laws for impregnated diamond tools for a given state of wear. Int J Rock Mech Min 73:184–193

Gurevich B, Pervukhina M, Makarynska D (2011) An analytic model for the stress-induced anisotropy of dry rocks. Geophysics 76(3):125–133

Hallbauer DK, Wagner H, Cook NGW (1973) Some observations concerning the microscopic and mechanical behaviour of quartzite specimens in stiff, triaxial compression tests. Int J Rock Mech Min Geomech Abstr 10:713–726

Hareland GA (2010) Drilling rate model for roller cone bits and its application. In: Proceedings of the CPS/SPE International Oil & Gas Conference, Held in Beijing, China; 2010. p. 8–10.

He MM, Zhang ZQ, Ren J, Huan J, Li GF, Chen YS, Li N (2019a) Deep convolutional neural network for fast determination of the rock strength parameters using drilling data. Int J Rock Mech Min 123:2

He MM, Li N, Zhang ZQ, Yao XC, Chen YS, Zhu CH (2019b) An empirical method for determining the mechanical properties of jointed rock mass using drilling energy. Int J Rock Mech Min 116:64–74

He MM, Li N, Zhu CH, Chen YS, Wu H (2019c) Experimental investigation and damage modelling of salt rock subjected to fatigue loading. Int J Rock Mech Min 114:17–23

He MM, Li N, Yao XC, Chen YS (2020a) A new method for prediction of rock quality designation in borehole using energy of rotary drilling. Rock Mech Rock Eng 53(7):3383–3394

He MM, Zhang ZQ, Zheng J, Chen FF, Li N (2020b) A new perspective on the constant m(i) of the Hoek–Brown failure criterion and a new model for determining the residual strength of rock. Rock Mech Rock Eng 53(9):3953–3967

He MM, Li N, Zhu J, Chen YS (2020c) Advanced prediction for field strength parameters of rock using drilling operational data from impregnated diamond bit. J Petrol Sci Eng 187:106847

He MM, Zhang ZQ, Zhu JW, Li N, Li GF, Chen YS (2021) Correlation between the rockburst proneness and friction characteristics of rock materials and a new method for rockburst proneness prediction: Field demonstration. J Petrol Sci Eng 2021:108997

Hoek E, Brown ET (1980) Underground excavations in rock. CRC Press, Boca Raton, pp 157–165

Ismael MA, Imam HF, El-Shayeb Y (2014) A simplified approach to directly consider intact rock anisotropy in Hoek–Brown failure criterion. J Rock Mech Geotech 6(5):486–492

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics. Blackwell Pub, Oxford

Kalantari S, Hashemolhosseini H, Baghbanan A (2018) Estimating rock strength parameters using drilling data. Int J Rock Mech Min 104:45–52

Lebedev AV, Bredikhin VV, Bretshtein YS (2012) Correlation between elastic anisotropy and magnetic susceptibility anisotropy of sedimentary and metamorphic rock. Acoust Phys 58(3):354–362

Lhomme T (1999) Frictional contact at a rock–tool interface: an experimental study. Master’s thesis, University of Minnesota; 1999.

Li Z, Itakura K (2012) An analytical drilling model of drag bits for evaluation of rocks strength. Soils Found 52(2):216–227

Munoz H, Taheri A, Chanda EK (2016) Rock drilling performance evaluation by an energy dissipation-based rock brittleness index. Rock Mech Rock Eng 49(8):3343–3355

Nara Y (2015) Effect of Anisotropy on the long-term strength of granite. Rock Mech Rock Eng 48:959–969

Nishimatsu Y (1993) Theories of rock cutting. In: Hudson JA (ed) Comprehensive rock engineering. Pergamon Press, Oxford, pp 647–662

Palassi M, Emami V (2014) A new nail penetration test for estimation of rock strength. Int J Rock Mech Min 66:124–127

Ramamurthy T (1993) Strength and modulus responses of anisotropic rocks. Comprehensive rock engineering. Pergamon Press, Oxford, pp 313–329

Richard T, Germay C, Detournay E (2007) A simplified model to explore the root cause of stick–slip vibrations in drilling systems with drag bits. J Sound Vib 305:432–456

Richard T, Dagrain F, Poyol E, Detournay E (2012) Rock strength determination from scratch tests. Eng Geol 147–148:91–100

Rostamsowlat I, Akbarib B, Evans B (2018a) Analysis of rock cutting process with a blunt PDC cutter under different wear flat inclination angles. J Petrol Sci Eng 171:771–783

Rostamsowlat I (2018b) Effect of cutting tool properties and depth of cut in rock cutting: an experimental study. Rock Mech Rock Eng 51:1715–1728

Saroglou H, Tsiambaos G (2008) A modified Hoek–Brown failure criterion for anisotropic intact rock. Int J Rock Mech Min 45(2):223–234

Saroglou C, Qi SW, Guo S, Wu F (2019) ARMR, a new classification system for the rating of anisotropic rock masses. B Eng Geo Environ 78(5):3611–3626

Shen BT, Siren T, Rinne M (2015) Modelling fracture propagation in anisotropic rock mass. Rock Mech Rock Eng 48(3):1067–1108

Taheri A, Qao Q, Chanda E (2016) Drilling penetration rate estimation using rock drillability characterization index. J Inst Eng: Series d 97(2):159–170

Teale R (1965) The concept of specific energy in rock drilling. Int J Rock Mech Min 2:57–73

Thomsen L (1986) Weak elastic anisotropy. Geophysics 51:1954–1966

Wang Q, Gao S, Jiang B, Li S, He M, Gao H, Qin Q (2018a) Rock-cutting mechanics model and its application based on slip-line theory. Int J Geo Mech 18(5):04018025

Wang Q, Qin Q, Jiang B, Li SC (2018b) Upper bound analytic mechanics model for rock cutting and its application in field testing. Tunn Undergr Space Technol 73:287–294

Wang Q, Gao HK, Yu HC, Jiang B, Liu BH (2019) Method for measuring rock mass characteristics and evaluating the grouting-reinforced effect based on digital drilling. Rock Mech Rock Eng 52:841–851

Wang HT, He MM, Zhang ZQ, Zhu JW (2022) Determination of the constant m(i) in the Hoek–Brown criterion of rock based on drilling parameters. Int J Min Sci Technol 32(4):747–759

Yan ZM, Wang K, Zang J, Wang C, Liu A (2019) Anisotropic coal permeability and its stress sensitivity. Int J Mini Sci Techno 29:507–511

Acknowledgements

This study is sponsored by the National Natural Science Foundation of China (Grants No. 42177158, 11902249 and 11872301), Key Research and Development project of Shaanxi Province (No. 2022SF-412), Education Bureau of Shaanxi Province in China (Grant No. 20JS093). Opening fund of State Key Laboratory of Geohazard Prevention and Geoenvironment Protection (Chengdu University of Technology) (Grants No. SKLGP2022K005). Open subject of Urban Geology and Underground Space Engineering Technology Research Center of Shaanxi Province (2022KT-01). The financial support provided by this sponsor is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, M., Wang, H., Ma, C. et al. Evaluating the Anisotropy of Drilling Mechanical Characteristics of Rock in the Process of Digital Drilling. Rock Mech Rock Eng 56, 3659–3677 (2023). https://doi.org/10.1007/s00603-023-03242-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03242-1