Abstract

The dynamic fracture toughness of rock materials under blast load is the basis for studying the stability of rock blasting engineering. To study the dynamic fracture characteristics of sandstone with an explosive load, the initiation and propagation times of pre-crack samples with different lengths were obtained through physical experiments. The experimental–numerical method was used to obtain the stress intensity factor (SIF) curve and the crack initiation toughness of the specimens with different pre-crack lengths. By comparing and analyzing the dynamic SIF and explosion load curves at different pre-crack lengths, the following results and conclusions were obtained: (1) a polyvinylidene fluoride pressure gauge effectively measured the blast pressure curves at the blast hole wall and the blast hole with a diameter of 40 mm in the presence of a coupling water medium that could effectively avoid the formation of crushed zones and reduce the attenuation of the blast energy. (2) The crack-tip SIF curves were well correlated to the blast pressure curves with a minimal SIF lagging of 0.3–2.9 μs after the peak of the blast pressure curve and a maximum SIF lagging of 0.1–22.9 μs after the time when the peak blast pressure decayed to zero, and the lagging time increased with the pre-crack length. (3) The crack was affected by the reflected wave during the propagation process, and the reflected wave did not affect the crack propagation within 0–109.8 μs. The longer the pre-crack length was, the longer the reflected wave influence time was. (4) The SIF at the pre-crack tip was controlled to a degree such that the first wave was superposed on the surface wave of the crack surface. Both the peak value of the stress intensity factor curve and the crack initiation toughness value decreased with the increase of the pre-crack length, and an obvious separation inflection point appeared on the stress intensity factor curve with the increase of the pre-crack length. (5) The implications of these findings particularly regarding the test method for dynamic fracture of materials tested by explosion method are discussed.

Highlights

-

The water coupling technology for loading hole effectively avoids the formation of crushing circle in loading hole.

-

The pressure time range of the loading hole is accurately measured by a PVDF pressure sensor.

-

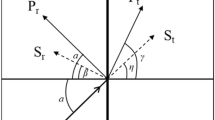

The stress intensity factor curves of internal single-cracked square plate specimens under blast loading are significantly influenced by the superposition of the first wave and the surface wave on the crack surface.

-

The degree of superposition between the first wave and the surface wave on the crack surface is significantly affected by the length of the prefabricated crack.

-

The average loading rate of the stress intensity factor curve varies from 1036 GPa·m1/2·s−1 to 2198GPa·m1/2·s−1 with the change of pre-crack length.

Similar content being viewed by others

Abbreviations

- SIF:

-

Stress intensity factor

- \(r_{{\text{c}}}\) :

-

Radius of damage zone

- \(Q_{{\text{v}}}\) :

-

Explosion heat of PETN

- \(\sigma_{{\text{c}}}\) :

-

The uniaxial compressive strength of the sandstone specimen

- \(2a\) :

-

The crack length

- \(\lambda\) :

-

Wavelength

- \(c_{{\text{P}}}\) :

-

The longitudinal wave velocity

- \(c_{{\text{s}}}\) :

-

The transverse wave velocity

- \(c_{{\text{R}}}\) :

-

The surface wave velocity

- \(t_{{\text{f}}}\) :

-

The crack initiation time

References

Bao-Xin C, Qin-Rong Y (2005) Basics of blasting dynamics. Hubei Science and Technology Press, Wuhan

Bauer SJ, Song B, Sanborn B (2019) dynamic compressive strength of rock salts. Int J Rock Mech Min 113:112–120

Baytos JF (1980) Lasl explosive property data. Univ of California Press, Berkeley

Blair DP (2007) A comparison of Heelan and exact solutions for seismic radiation from a short cylindrical charge. Geophysics 72(2):E33–E41

Cai S, Liu J, Zhang P, Li C, Cheng Y (2020) Dynamic response of sandwich panels with multi-layered aluminum foam/uhmwpe laminate cores under air blast loading. Int J Impact Eng 138:103475

Chi LY, Zhang ZX, Aalberg A, Yang J, Li CC (2019a) Fracture processes in granite blocks under blast loading. Rock Mech Rock Eng 52(3):853–868

Chi LY, Zhang Z, Aalberg A, Yang J, Li CC (2019b) Measurement of shock pressure and shock-wave attenuation near a blast hole in rock. Int J Impact Eng 125:27–38

Dai F, Xu Y, Zhao T, Xu N, Liu Y (2016) Loading-rate-dependent progressive fracturing of cracked chevron-notched Brazilian disc specimens in split Hopkinson pressure bar tests. Int J Rock Mech Min 88:49–60

Ding JC, Xu W (2021) Determination of mode I interlaminar fracture toughness of composite by a wedge-insert double cantilever beam and the nonlinear J integral. Compos Sci Technol 1–21

Fan Z, Liu Y, Xu P (2016) Blast resistance of metallic sandwich panels subjected to proximity underwater explosion. Int J Impact Eng 93:128–135

Field JE, Walley SM, Proud WG, Goldrein HT, Siviour CR (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30(7):725–775

Fujii K, Yasuda E, Tanabe Y (2001) Dynamic mechanical properties of polycrystalline graphites and a 2D-C/C composite by plate impact. Int J Impact Eng 25(5):473–491

Gong F, Zhao G (2014) Dynamic indirect tensile strength of sandstone under different loading rates. Rock Mech Rock Eng 47(6):2271–2278

Hernandez JA, Kedir N, Lim BH, Chen W, Tallman TN (2020) An experimental study on the piezoresistive and mechanical behavior of carbon nanocomposites subject to high-rate elastic loading. Compos Sci Technol 198:108285

Hu Y, Liu M, Wu X, Zhao G, Li P (2018) Damage-vibration couple control of rock mass blasting for high rock slopes. Int J Rock Mech Min 103:137–144

Ittner H, Olsson M, Johansson D, Schunnesson H (2019) Multivariate evaluation of blast damage from emulsion explosives in tunnels excavated in crystalline rock. Tunn Undergr Sp Tech 85:331–339

Kim J, Paulino GH (2005) Consistent formulations of the interaction integral method for fracture of functionally graded materials. J Appl Mech 72(3):351–364

Li JC, Li NN, Chai SB, Li HB (2018) Analytical study of ground motion caused by seismic wave propagation across faulted rock masses. Int J Numer Anal Methods 42(1):95–109

Liu K, Zhang QB, Wu G, Li JC, Zhao J (2019a) Dynamic mechanical and fracture behaviour of sandstone under multiaxial loads using a triaxial Hopkinson bar. Rock Mech Rock Eng 52(7):2175–2195

Liu R, Zhu Z, Li M, Liu B, Wan D (2019b) Study on dynamic fracture behavior of mode I crack under blasting loads. Soil Dyn Earthq Eng 117:47–57

Liu R, Zhu Z, Li Y, Liu B, Wan D, Li M (2020) Study of rock dynamic fracture toughness and crack propagation parameters of four brittle materials under blasting. Eng Fract Mech 225:1–18

Ma J, Dong L, Zhao G, Li X (2019) Qualitative method and case study for ground vibration of tunnels induced by fault-slip in underground mine. Rock Mech Rock Eng 52(6):1887–1901

Muthurajan H, Sivabalan R, Pon Saravanan N, Talawar MB (2009) Computer code to predict the heat of explosion of high energy materials. J Hazard Mater 161(2–3):714–717

Nagayama K, Mori Y, Hidaka K (1999) Shock Compression Experiments On Several Polymers in the 1 Gpa Stress Region. J Mater Process Tech 85(1–3):20–24

Paulino GH, Kim JH (2004) A new approach to compute T-stress in functionally graded materials by means of the interaction integral method. Eng Fract Mech 71(13):1907–1950

Persson P, Holmberg R, Lee J (1994) Rock blasting and explosives engineering. CRC Press, Boca Raton

Rice JR (1968) A path integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35(2):379–386

Sato Y, Yoshida M, Nagayama K, Horie Y (2008) Stress–strain relationships of polycarbonate over a wide range of strain rate, including a shock wave regime. Int J Impact Eng 35(12):1778–1783

Song SH, Paulino GH (2006) Dynamic stress intensity factors for homogeneous and smoothly heterogeneous materials using the interaction integral method. Int J Solids Struct 43(16):4830–4866

Wang QZ, Gou XP, Fan H (2012) The minimum dimensionless stress intensity factor and its upper bound for ccnbd fracture toughness specimen analyzed with straight through crack assumption. Eng Fract Mech 82:1–8

Wang Z, Ma L, Yu H, Wu L (2014) Dynamic stress intensity factors for homogeneous and non-homogeneous materials using the interaction integral method. Eng Fract Mech 128:8–21

Zhang QB, Zhao J (2014) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47(4):1411–1478

Zhang Z, Yang F, Liu Y, Wang L (2020) J-integral evaluation of a mode I crack in gradient nanocrystalline metals. Mater Today Commun 25:101328

Zhao J (2000) Applicability of Mohr–Coulomb and Hoek–Brown strength criteria to the dynamic strength of brittle rock. Int J Rock Mech Min Sci (oxford, England: 1997) 37(7):1115–1121

Zhu ZM, Xu WT, Feng RQ (2016) A new method for measuring mode-I dynamic fracture toughness of rock under blasting loads. Exp Techniques 40(3):899–905

Acknowledgements

This work was supported by the National Natural Science Foundation of Southwest University of Science and Technology (19zx7168); Shock and Vibration of Engineering Materials and Structures Key Laboratory of Sichuan Province (19kfgk07).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All co-authors have reviewed and agreed with the contents of the manuscript and there is no financial or other conflicts of interest to report. We certify that the submission is original work and is not under review at any other publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, D., Yang, W., Liu, C. et al. Testing of Mode-I Fracture Toughness of Sandstone Based on the Fracturing Mechanism of an Explosion Stress Wave. Rock Mech Rock Eng 55, 7731–7745 (2022). https://doi.org/10.1007/s00603-022-03047-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03047-8