Abstract

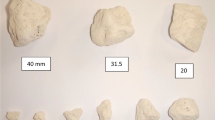

Crushing of rockfill grains is one of the most important issues in the stability study of rockfill dams/embankments. In engineering applications, crushing characteristics of a rockfill grain depend strongly on its number of contact points with neighboring grains. The present work aims to propose a breakage criterion including the effects of coordination number, which refers to the increase of grain strength with the redistribution of stress towards hydrostatic stress conditions due to the continual crushing of neighboring grains. In order to analyze the influence of coordination number on grain crushing, single-particle crushing tests with different coordination numbers are first simulated by a bonded particle model using the discrete-element method (DEM). The mechanical confinement effects of neighboring grains are investigated by installing rigid walls around crushable agglomerates. One observes that the failure pattern and strength of agglomerates are significantly affected by the coordination number. The grain strength generally increases with increasing coordination number. Based on the results obtained at the grain scale, a new breakage criterion is proposed for rockfill materials. The proposed criterion is then embedded in a population balance model in DEM. The oedometer tests with three different grain sizes are simulated using the proposed criterion. In order to avoid the unrealistic mechanical response and reduce the energy accumulation in the particle spawning, a new numerical procedure is adopted in the simulations. The simulated stress–strain curve, normal compression line, and particle size distribution are in agreement with the experimental results. Comparison between the proposed criterion and some previous criteria illustrates the merits of the new criterion. The micro-responses of the samples, including the evolution of average coordination number and average particle stress, are also discussed. Discrete-element modeling and micromechanical analysis will enhance the understanding of crushing and deformation behaviors of rockfill materials.

Highlights

-

The influence of coordination number on the failure pattern and crushing strength of rockfill grains is investigated at the grain scale.

-

A new breakage criterion is proposed for the crushing of rockfill grains with the consideration of coordination number effects.

-

A new numerical procedure is adopted to avoid the unrealistic mechanical response in the particle spawning.

-

By simulating the oedometer tests with three different grain sizes, the crushing characteristics of rockfill materials are studied at the structure scale.

-

Micro-mechanical analysis and discrete-element modeling will enhance the understanding of the crushing and deformation behaviors of rockfill materials.

Similar content being viewed by others

References

Alonso EE, Tapias M, Gili J (2012) Scale effects in rockfill behaviour. Géotech Lett 2:155–160

Altuhafi FN, Coop MR (2011) Changes to particle characteristics associated with the compression of sands. Géotechnique 61:459–471

ASTM I (2017) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM D 2487-17e1

Åström JA, Herrmann HJ (1998) Fragmentation of grains in a two-dimensional packing. Eur Phys J B 5:551–554

Ben-Nun O, Einav I (2008) A refined DEM study of grain size reduction in uniaxial compression. In: Proceedings of the 12th international conference of the international association for computer methods and advances in geomechanics (IACMAG), Goa, India, pp 702–708

Ben-Nun O, Einav I (2010) The role of self-organization during confined comminution of granular materials. Philos Trans Roy Soc A 368:231–247

Ciantia MO, Arroyo M, Gens A, Calvetti F (2014) Particle failure in DEM models of crushable soil response. In: Hicks MA, Brinkgreve RBJ, Rohe A (eds) Numerical methods in geotechnical engineering, vol 1. CRC Press/Balkema, Leiden, pp 345–350

Ciantia MO, Arroyo M, Calvetti F, Gens A (2015) An approach to enhance efficiency of DEM modelling of soils with crushable grains. Géotechnique 65:91–110

Cil MB, Alshibli KA (2012) 3D assessment of fracture of sand particles using discrete element method. Géotech Lett 2:161–166

Cil MB, Alshibli KA (2014) 3D evolution of sand fracture under 1D compression. Géotechnique 64:351–364

Cil MB, Sohn C, Buscarnera G (2020) DEM modeling of grain size effect in brittle granular soils. J Eng Mech 146:04019138

Coop MR, Lee I (1992) The behaviour of granular soils at elevated stresses. In: Predictive soil mechanics: proceedings of the Wroth Memorial Symposium held at St Catherine’s College, Oxford, 27-29 July 1992, Thomas Telford Publishing, pp 186–198

Coop MR, Sorensen KK, Freitas TB, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Géotechnique 54:157–163

Couroyer C, Ning Z, Ghadiri M (2000) Distinct element analysis of bulk crushing: effect of particle properties and loading rate. Powder Technol 109:241–254

Daouadji A, Hicher PY (2010) An enhanced constitutive model for crushable granular materials. Int J Numer Anal Methods Geomech 34:555–580

Daouadji A, Hicher PY, Rahma A (2001) An elastoplastic model for granular materials taking into account grain breakage. Eur J Mech A-Solid 20:113–137

de Bono JP, McDowell GR (2015) An insight into the yielding and normal compression of sand with irregularly-shaped particles using DEM. Powder Technol 271:270–277

de Bono JP, McDowell GR (2016a) The fractal micro mechanics of normal compression. Comput Geotech 78:11–24

de Bono JP, McDowell GR (2016b) Particle breakage criteria in discrete-element modelling. Géotechnique 66:1014–1027

de Bono JP, McDowell GR (2020) On the packing and crushing of granular materials. Int J Solids Struct 187:133–140

Devroye L (2006) Chapter 4 nonuniform random variate generation. In: Henderson SG, Nelson BL (eds) Simulation. Volume 13 of Handbooks in operations research and management science. Elsevier, pp 83–121

Duriez J, Scholtès L, Donzé FV (2016) Micromechanics of wing crack propagation for different flaw properties. Eng Fract Mech 153:378–398

Einav I (2007) Breakage mechanics-part I: theory. J Mech Phys Solids 55:1274–1297

Elghezal L, Jamei M, Georgopoulos IO (2013) DEM simulations of stiff and soft materials with crushable particles: an application of expanded perlite as a soft granular material. Granul Matter 15:685–704

Eliáš J (2014) Simulation of railway ballast using crushable polyhedral particles. Powder Technol 264:458–465

Esnault VPB, Roux JN (2013) 3D numerical simulation study of quasistatic grinding process on a model granular material. Mech Mater 66:88–109

Fu R, Hu X, Zhou B (2017) Discrete element modeling of crushable sands considering realistic particle shape effect. Comput Geotech 91:179–191

Guida G, Casini F, Viggiani GM, Ando E, Viggiani G (2018) Breakage mechanisms of highly porous particles in 1D compression revealed by X-ray tomography. Géotech Lett 8:155–160

Gundepudi M, Sankar B, Mecholsky J Jr, Clupper D (1997) Stress analysis of brittle spheres under multiaxial loading. Powder Technol 94:153–161

Hanley KJ, O’Sullivan C, Huang X (2015) Particle-scale mechanics of sand crushing in compression and shearing using DEM. Soils Found 55:1100–1112

Huang J, Xu S, Yi H, Hu S (2014) Size effect on the compression breakage strengths of glass particles. Powder Technol 268:86–94

Huang Q, Zhou W, Ma G, Ng TT, Xu K (2020) Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci Front 11:401–411

Huillca Y, Silva M, Ovalle C, Quezada JC, Carrasco S, Villavicencio GE (2021) Modelling size effect on rock aggregates strength using a DEM bonded-cell model. Acta Geotech 16:699–709

Jaeger JC (1967) Failure of rocks under tensile conditions. Int J Rock Mech Min Sci 4:219–227

Kh AB, Mirghasemi AA, Mohammadi S (2011) Numerical simulation of particle breakage of angular particles using combined DEM and FEM. Powder Technol 205:15–29

Kozicki J, Donze FV (2008) A new open-source software developed for numerical simulations using discrete modeling methods. Comput Method Appl Mech 197:4429–4443

Kozicki J, Donze FV (2009) YADE-OPEN DEM: an open-source software using a discrete element method to simulate granular material. Eng Comput 26:786–805

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. J Geotech Eng-ASCE 122:309–316

Li S, Kasyap SS, Senetakis K (2021) A study on the failure behavior of sand grain contacts with Hertz modeling, image processing, and statistical analysis. Sensors 21:4611

Lim WL, McDowell GR (2007) The importance of coordination number in using agglomerates to simulate crushable particles in the discrete element method. Géotechnique 57:701–705

Liu X, Wang Y, Zhang Z, Yu Y (2021) DEM investigation on the breakage of spherical aggregate under multi-contact loadings. AIChE J 67:e17294

Lobo-Guerrero S, Vallejo LE, Vesga LF (2006) Visualization of crushing evolution in granular materials under compression using DEM. Int J Geomech 6:195–200

Luzzani L, Coop MR (2002) On the relationship between particle breakage and the critical state of sands. Soils Found 42:71–82

Marketos G, Bolton MD (2009) Compaction bands simulated in discrete element models. J Struct Geol 31:479–490

Marsaglia G et al (1972) Choosing a point from the surface of a sphere. Ann Math Stat 43:645–646

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42:139–145

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40:133–141

McDowell GR, Bolton MD (1998) On the micromechanics of crushable aggregates. Géotechnique 48:667–679

McDowell GR, de Bono JP (2013) On the micro mechanics of one-dimensional normal compression. Géotechnique 63:895–908

McDowell GR, Humphreys A (2002) Yielding of granular materials. Granul Matter 4:1–8

Nakata AFL, Hyde M, Hyodo H, Murata (1999) A probabilistic approach to sand particle crushing in the triaxial test. Géotechnique 49:567–583

Nakata Y, Hyodo M, Hyde AF, Kato Y, Murata H (2001a) Microscopic particle crushing of sand subjected to high pressure one-dimensional compression. Soils Found 41:69–82

Nakata Y, Kato Y, Hyodo M, Hyde AF, Murata H (2001b) One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found 41:39–51

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Rad MM, Safikhani S, Bauer E (2019) Influence of the loading condition on single grain crushing in DEM simulation. Period Polytech-Civ 63:1152–1158

Salami Y, Dano C, Hicher PY, Colombo G, Denain P (2015) The effects of the coordination on the fragmentation of a single grain. In: IOP conference series: earth and environmental science. IOP Publishing, p 012015

Salami Y, Dano C, Hicher PY (2019) An experimental study on the influence of the coordination number on grain crushing. Eur J Environ Civ Eng 23:432–448

Sandeep CS, Li S, Senetakis K (2021) Scale and surface morphology effects on the micromechanical contact behavior of granular materials. Tribol Int 159:106929

Scholtès L, Donzé FV (2013) A DEM model for soft and hard rocks: role of grain interlocking on strength. J Mech Phys Solids 61:352–369

Shi D, Cao D, Deng Y, Xue J (2021) DEM investigations of the effects of intermediate principal stress ratio and particle breakage on the critical state behaviors of granular soils. Powder Technol 379:547–559

Sukumaran B, Einav I, Dyskin A (2006) Qualitative assessment of the influence of coordination number on crushing strength using DEM. In: Proc. of the fifth world congress on particle technology, 23–27 April, Orlando, Florida, USA

Tapias M, Alonso EE, Gili JA (2015) A particle model for rockfill behaviour. Géotechnique 65:975–994

Tarantino A, Hyde AF (2005) An experimental investigation of work dissipation in crushable materials. Géotechnique 55:575–584

Todisco MC, Coop MR, Guo Q, Senetakis K (2015) The effect of the coordination number on particle crushing. In: International symposium on geomechanics from micro to macro, IS-Cambridge 2014. Taylor and Francis-Balkema, pp 1063–1068

Todisco M, Wang W, Coop M, Senetakis K (2017) Multiple contact compression tests on sand particles. Soils Found 57:126–140

Tong CX, Zhang KF, Zhang S, Sheng D (2019) A stochastic particle breakage model for granular soils subjected to one-dimensional compression with emphasis on the evolution of coordination number. Comput Geotech 112:72–80

Tsoungui O, Vallet D, Charmet JC (1999) Numerical model of crushing of grains inside two-dimensional granular materials. Powder Technol 105:190–198

Turcotte DL (1986) Fractals and fragmentation. J Geophys Res-Sol Earth 91:1921–1926

Tyler SW, Wheatcraft SW (1989) Application of fractal mathematics to soil water retention estimation. Soil Sci Soc Am J 53:987–996

Varadarajan A, Sharma KG, Venkatachalam K, Gupta AK (2003) Testing and modeling two rockfill materials. J Geotech Geoenviron 129:206–218

Wang P, Arson C (2016) Discrete element modeling of shielding and size effects during single particle crushing. Comput Geotech 78:227–236

Wang W, Coop M (2016) An investigation of breakage behaviour of single sand particles using a high-speed microscope camera. Géotechnique 66:984–998

Wang J, Yan H (2013) On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int J Numer Anal Methods Geomech 37:832–854

Wang P, Karatza Z, Arson C (2019) DEM modelling of sequential fragmentation of zeolite granules under oedometric compression based on XCT observations. Powder Technol 347:66–75

Wang ZY, Fang YF, Feng WQ, Tian XJ, Lin JF (2022) Comparative study on particle size effect of crushable granular soils through DEM simulations. Lithosphere 2021:1608454

Weerasekara NS, Powell MS, Cleary PW, Tavares LM, Evertsson M, Morrison RD, Quist J, Carvalho RM (2013) The contribution of DEM to the science of comminution. Powder Technol 248:3–24

Xiao Y, Liu H, Chen Y, Jiang J, Zhang W (2014) Testing and modeling of the state-dependent behaviors of rockfill material. Comput Geotech 61:153–165

Xiao Y, Liu H, Ding X, Chen Y, Jiang J, Zhang W (2016) Influence of particle breakage on critical state line of rockfill material. Int J Geomech 16:04015031

Xiao Y, Meng M, Daouadji A, Chen Q, Wu Z, Jiang X (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11:375–388

Xu M, Hong J, Song E (2017) DEM study on the effect of particle breakage on the macro-and micro-behavior of rockfill sheared along different stress paths. Comput Geotech 89:113–127

Ye Y, Zeng Y, Sun H, Liu Y, Chen X, Ma W (2021) An experimental study on the influence of multiple contacts and size on contact behavior of marble sphere. Granul Matter 23:1–13

Zhang, C., Zhao, Y. & Bai, Q. 3D DEM method for compaction and breakage characteristics simulation of broken rock mass in goaf. Acta Geotech. 17, 2765–2781 (2022). https://doi-org.ressources-electroniques.univ-lille.fr/10.1007/s11440-021-01379-3

Zhao X (2021) Experimental study and numerical modeling of crushing and mechanical behavior of rockfill materials: influence of particle size. Ph.D. thesis, University of Lille, France

Zhao B, Wang J, Coop MR, Viggiani G, Jiang M (2015) An investigation of single sand particle fracture using X-ray micro-tomography. Géotechnique 65:625–641

Zhao CF, Pinzón G, Wiebicke M, Andò E, Kruyt NP, Viggiani G (2021) Evolution of fabric anisotropy of granular soils: X-ray tomography measurements and theoretical modelling. Comput Geotech 133:104046

Zheng W, Tannant DD (2018) Grain breakage criteria for discrete element models of sand crushing under one-dimensional compression. Comput Geotech 95:231–239

Zhou W, Yang L, Ma G, Chang X, Cheng Y, Li D (2015) Macro-micro responses of crushable granular materials in simulated true triaxial tests. Granul Matter 17:497–509

Zhou W, Yang L, Ma G, Chang X, Lai Z, Xu K (2016) DEM analysis of the size effects on the behavior of crushable granular materials. Granul Matter 18:1–11

Zhou W, Wang D, Ma G, Cao X, Hu C, Wu W (2020) Discrete element modeling of particle breakage considering different fragment replacement modes. Powder Technol 360:312–323

Zhu F, Zhao J (2019) A peridynamic investigation on crushing of sand particles. Géotechnique 69:526–540

Acknowledgements

The authors gratefully acknowledge the financial support from the State Key Program of National Natural Science Foundation of China (No. U2040221), the Open Sharing Fund for the Large-scale Instruments of Hohai University (Nos. GX202205B; GX202204B), and the 111 Project (No. B13024). The first author gratefully acknowledges the financial support from China Scholarship Council (No. 201806710020). The oedometer test simulations in this paper have been done on the HPC Computing Mésocentre of University of Lille. The authors gratefully thank the anonymous reviewers for their constructive comments as well.

Author information

Authors and Affiliations

Contributions

XZ: conceptualization, methodology, software, writing—original draft, and funding acquisition. JZ: writing—review and editing, and funding acquisition. YW: writing—review and editing, and methodology. YJ: conceptualization, supervision, writing—review and editing, and methodology. J-BC: supervision, writing—review and editing, and methodology. HB: writing—review and editing, and methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Zhu, J., Wu, Y. et al. A Numerical Study on the Influence of Coordination Number on the Crushing of Rockfill Materials. Rock Mech Rock Eng 55, 6279–6300 (2022). https://doi.org/10.1007/s00603-022-02985-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02985-7