Abstract

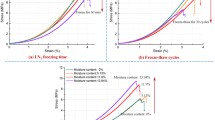

To determine the role of LN2-cooling in the fracturing process of the coal, the LN2-cooling process of the coal samples is divided into three states: initial state, frozen state, and freeze–thaw state. Changes in the mechanical properties and fracture behaviors of the coal samples under three states are systematically evaluated by a series of laboratory experiments. The thermal cracking behavior of the coal during LN2 freeze–thaw is revealed through a crack phase-field model. The results indicate that the compressive strength, elastic modulus, and fracture toughness of the frozen coal significantly increase, while they decrease for the freeze–thaw coal. The tensile strength of the coal under the freeze and freeze–thaw states has an obvious reduction, where a greater decrease for the freeze–thaw coal is induced. The fracture propagation process and induced fracture morphology of the coal under both the freeze and freeze–thaw states become complex, in which a greater change for the freeze–thaw coal is presented. The micro-fracture in the coal during LN2-cooling mainly comes from the temperature gradient and mismatch of thermal stress between adjacent mineral particles. Both fracture growth rate and fracture area in the LN2 thaw process are larger than that in the LN2 freeze process. The variations in the fracturing behaviors of the coal with different LN2 treatment states in the mechanical experiments are well explained by the numerical simulation results.

Highlights

-

The mechanical properties of the coal with different LN2 cooling states are studied systematically through laboratory experiments.

-

Effects of the LN2 cooling state on the crack propagation and fracture morphology of the coal in the mechanical tests are analyzed.

-

The micro-crack evolution process of the coal during the LN2 freeze–thaw is revealed through a crack phase-field model.

-

Both the crack propagation rate and induced crack area inside the coal during the LN2 thaw process are greater than that during the LN2 freeze process.

Similar content being viewed by others

Abbreviations

- CBM:

-

Coalbed methane

- QSGS:

-

Quartet structure generation set

- RA:

-

Rise time/amplitude

- \({\sigma }_{\mathrm{t}}\) :

-

Tensile strength

- \({K}_{\mathrm{I}}\) :

-

Mode I fracture toughness

- \({P}_{\mathrm{max}}\) :

-

Maximum loading

- \(D\) :

-

Diameter of the disk

- \({Y}_{I}\) :

-

Geometry factor

- \(t\) :

-

Time

- \(T\) :

-

Temperature

- \(\overline{T }\) :

-

Specified boundary temperature

- \(\overline{Q }\) :

-

Specified boundary heat source

- \(h\) :

-

Convective parameter of heat exchange

- \(Q\) :

-

Heat source

- \({c}_{\mathrm{p}}\) :

-

Heat capacity

- \(\rho\) :

-

Density of the coal

- \(k\) :

-

Heat conductivity

- \({\mathbf{n}}^{\mathrm{T}}\) :

-

Normal unit vector

- \({\varvec{\upsigma}}\) :

-

Stress tensor

- \({\mathbf{F}}_{\mathrm{V}}\) :

-

Volumetric force tensor

- \(\mathbf{D}\) :

-

Elasticity modulus tensor

- \(\mathbf{u}\) :

-

Displacement tensor

- SEM:

-

Scanning electron microscope

- AE:

-

Acoustic emission

- ISRM:

-

International Society for Rock Mechanics

- AF:

-

AE counts/duration

- \({{\varvec{\upvarepsilon}}}^{\mathrm{e}}\) :

-

Elastic strain

- \({{\varvec{\upvarepsilon}}}^{\mathrm{th}}\) :

-

Thermal strain

- \({T}_{0}\) :

-

Reference temperature

- \({{\varvec{\upalpha}}}_{\mathrm{T}}\) :

-

Thermal expansion tensor.

- \(\phi\) :

-

Phase field

- \(d\left(\phi \right)\) :

-

Damage function

- \({l}_{\mathrm{int}}\) :

-

Internal length scale

- \({H}_{\mathrm{d}}\) :

-

State variable function

- \({G}_{\mathrm{c}}\) :

-

Critical energy release rate

- \({G}_{\mathrm{c}0}\) :

-

Strain energy threshold

- \({W}_{\mathrm{s}0}^{+}\) :

-

Tensile part of the undamaged elastic strain energy density

- \({{\varvec{\upvarepsilon}}}_{\mathrm{el}}^{+}\) :

-

Tensile part of the elastic strain tensor

- \({{\varvec{\upvarepsilon}}}_{\mathrm{el},\mathrm{pi}}\) :

-

Principal value of the elastic strain tensor

- \({\mathbf{n}}_{i}\) :

-

Direction vector

- \(\mathbf{C}\) :

-

4th order elasticity tensor

- \({k}_{0}\) :

-

Initial thermal conductivity

- \(g\left(\phi \right)\) :

-

Stiffness weakening function

- \({\mathbf{D}}_{0}\) :

-

Initial elasticity modulus tensor

- \(\nu\) :

-

Poisson’s ratio

- \(E\) :

-

Elastic modulus

References

Anderson RL, Ratcliffe I, Greenwell HC, Williams PA, Cliffe S, Coveney PV (2010) Clay swelling—a challenge in the oilfield. Earth Sci Rev 98:201–216. https://doi.org/10.1016/j.earscirev.2009.11.003

Cai CZ, Gao F, Li GS, Huang ZW, Hou P (2016) Evaluation of coal damage and cracking characteristics due to liquid nitrogen cooling on the basis of the energy evolution laws. J Nat Gas Sci Eng 29:30–36. https://doi.org/10.1016/j.jngse.2015.12.041

Cai CZ, Gao F, Yang YG (2018) The effect of liquid nitrogen cooling on coal cracking and mechanical properties. Energ Explor Exploit 36:1609–1628. https://doi.org/10.1177/0144598718766630

Cha MS, Yin XL, Kneafsey T, Johanson B, Alqahtani N, Miskimins J, Patterson T, Wu YS (2014) Cryogenic fracturing for reservoir stimulation—laboratory studies. J Petrol Sci Eng 124:436–450. https://doi.org/10.1016/j.petrol.2014.09.003

Christensen NI (1996) Poisson’s ratio and crustal seismology. J Geophys Res Sol Ea 101:3139–3156. https://doi.org/10.1029/95JB03446

Chu YP, Zhang DM (2019) Study on the pore evolution law of anthracite coal under liquid nitrogen freeze-thaw cycles based on infrared thermal imaging and nuclear magnetic resonance. Energy Sci Eng 7:3344–3354. https://doi.org/10.1002/ese3.505

Chu DY, Li X, Liu ZL (2017) Study the dynamic crack path in brittle material under thermal shock loading by phase field modeling. Int J Fracture 208:115–130. https://doi.org/10.1007/s10704-017-0220-4

Chu YP, Sun HT, Zhang DM, Yu G (2020) Nuclear magnetic resonance study of the influence of the liquid nitrogen freeze-thaw process on the pore structure of anthracite coal. Energy Sci Eng 8:1681–1692. https://doi.org/10.1002/ese3.624

Coetzee S, Neomagus HWJP, Bunt JR, Strydom CA, Schobert HH (2014) The transient swelling behaviour of large (-20+16 mm) South African coal particles during low-temperature devolatilisation. Fuel 136:79–88. https://doi.org/10.1016/j.fuel.2014.07.021

Dal Bo M, Cantavella V, Sanchez E, Hotza D, Gilabert FA (2013) Fracture toughness and temperature dependence of Young’s modulus of a sintered albite glass. J Non Cryst Solids 363:70–76. https://doi.org/10.1016/j.jnoncrysol.2012.12.001

Dong J, Cheng YP, Jin K, Zhang H, Liu QQ, Jiang JY, Hu BA (2017) Effects of diffusion and suction negative pressure on coalbed methane extraction and a new measure to increase the methane utilization rate. Fuel 197:70–81. https://doi.org/10.1016/j.fuel.2017.02.006

Du K, Li XF, Tao M, Wang SF (2020a) Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int J Rock Mech Min 133:104411. https://doi.org/10.1016/j.ijrmms.2020.104411

Du ML, Gao F, Cai CZ, Su SJ, Wang ZK (2020b) Study on the surface crack propagation mechanism of coal and sandstone subjected to cryogenic cooling with liquid nitrogen. J Nat Gas Sci Eng 81:103436. https://doi.org/10.1016/j.jngse.2020.103436

Garcia VJ, Marquez CO, Zuniga-Suarez AR, Zuniga-Torres BC, Villalta-Granda LJ (2017) Brazilian test of concrete specimens subjected to different loading geometries: review and new insights. Int J Concr Struct M 11:343–363. https://doi.org/10.1007/s40069-017-0194-7

Hou P, Gao F, Gao YN, Yang YG, Cai CZ (2018) Changes in breakdown pressure and fracture morphology of sandstone induced by nitrogen gas fracturing with different pore pressure distributions. Int J Rock Mech Min 109:84–90. https://doi.org/10.1016/j.ijrmms.2018.06.006

Hou P, Liang X, Gao F, Dong JB, He J, Xue Y (2021a) Quantitative visualization and characteristics of gas flow in 3D pore-fracture system of tight rock based on lattice Boltzmann simulation. J Nat Gas Sci Eng 89:103867. https://doi.org/10.1016/j.jngse.2021.103867

Hou P, Liang X, Zhang Y, He J, Gao F, Liu J (2021b) 3D multi-scale reconstruction of fractured shale and influence of fracture morphology on shale gas flow. Nat Resour Res 30:2463–2481. https://doi.org/10.1007/s11053-021-09861-1

Hou P, Su SJ, Liang X, Gao F, Cai CZ, Yang YG, Zhang ZZ (2021c) Effect of liquid nitrogen freeze–thaw cycle on fracture toughness and energy release rate of saturated sandstone. Eng Fract Mech 258:108066

Hou P, Xue Y, Gao F, Dou FK, Su SJ, Cai CZ, Zhu CH (2022) Effect of liquid nitrogen cooling on mechanical characteristics and fracture morphology of layer coal under Brazilian splitting test. Int J Rock Mech Min 151:105026

Hulan T, Stubna I (2020) Young’s modulus of kaolinite-illite mixtures during firing. Appl Clay Sci 190:105584. https://doi.org/10.1016/j.clay.2020.105584

Jin XM, Gao JL, Su CD, Liu JJ (2019) Influence of liquid nitrogen cryotherapy on mechanic properties of coal and constitutive model study. Energ Source Part A 41:2364–2376. https://doi.org/10.1080/15567036.2018.1563245

Lao XB, Xu XY, Jiang WH, Liang J, Miao LF, Wu Q (2020) Influences of impurities and mineralogical structure of different kaolin minerals on thermal properties of cordierite ceramics for high-temperature thermal storage. Appl Clay Sci 187:105485. https://doi.org/10.1016/j.clay.2020.105485

Li J, Song F, Jiang CP (2013) Direct numerical simulations on crack formation in ceramic materials under thermal shock by using a non-local fracture model. J Eur Ceram Soc 33:2677–2687. https://doi.org/10.1016/j.jeurceramsoc.2013.04.012

Li H, Lin BQ, Chen ZW, Hong YD, Zheng CS (2017) Evolution of coal petrophysical properties under microwave irradiation stimulation for different water saturation conditions. Energ Fuel 31:8852–8864. https://doi.org/10.1021/acs.energyfuels.7b00553

Li B, Ren YJ, Lv XQ (2020a) The evolution of thermal conductivity and pore structure for coal under liquid nitrogen soaking. Adv Civ Eng 2020:2748092. https://doi.org/10.1155/2020/2748092

Li HW, Zuo JP, Wang LG, Li PF, Xu XW (2020b) Mechanism of structural damage in low permeability coal material of coalbed methane reservoir under cyclic cold loading. Energies 13:519. https://doi.org/10.3390/en13030519

Liang X, Hou P, Xue Y, Yang XJ, Gao F, Liu J (2021a) A fractal perspective on fracture initiation and propagation of reservoir rocks under water and nitrogen fracturing. Fractals 29(7):2150189. https://doi.org/10.1142/S0218348X21501899

Liang X, Hou P, Yang XJ, Xue Y, Teng T, Gao F, Liu J (2021b) On estimating plastic zones and propagation angles for mixed mode I/II cracks considering fractal effect. Fractals. https://doi.org/10.1142/S0218348X22500116

Liew MS, Danyaro KU, Zawawi NAWA (2020) A comprehensive guide to different fracturing technologies: A review. Energies 13:3326. https://doi.org/10.3390/en13133326

Lim IL, Johnston IW, Choi SK (1993) Stress intensity factors for semicircular specimens under 3-point bending. Eng Fract Mech 44:363–382. https://doi.org/10.1016/0013-7944(93)90030-V

Linvill ML, Vandersande JW, Pohl RO (1984) Thermal-conductivity of feldspars. B Mineral 107:521–527

Liu DM, Yao YB, Tang DZ, Tang SH, Che Y, Huang WH (2009) Coal reservoir characteristics and coalbed methane resource assessment in Huainan and Huaibei coalfields, Southern North China. Int J Coal Geol 79:97–112. https://doi.org/10.1016/j.coal.2009.05.001

Liu ZD, Cheng YP, Dong J, Jiang JY, Wang L, Li W (2018) Master role conversion between diffusion and seepage on coalbed methane production: implications for adjusting suction pressure on extraction borehole. Fuel 223:373–384. https://doi.org/10.1016/j.fuel.2018.03.047

Liu J, Yao K, Xue Y, Zhang XX, Chong ZH, Liang X (2019) Study on fracture behavior of bedded shale in three-point-bending test based on hybrid phase-field modelling. Theor Appl Fract Mec 104:102382. https://doi.org/10.1016/j.tafmec.2019.102382

Liu J, Xue Y, Zhang Q, Yao K, Liang X, Wang SH (2020a) Micro-cracking behavior of shale matrix during thermal recovery: Insights from phase-field modeling. Eng Fract Mech 239:107301. https://doi.org/10.1016/j.engfracmech.2020.107301

Liu SM, Li XL, Wang DK (2020b) Numerical simulation of the coal temperature field evolution under the liquid nitrogen cold soaking. Arab J Geosci 13:1215. https://doi.org/10.1007/s12517-020-06237-2

Liu SM, Li XL, Wang DK, Zhang DM (2021) Experimental study on temperature response of different ranks of coal to liquid nitrogen soaking. Nat Resour Res 30:1467–1480. https://doi.org/10.1007/s11053-020-09768-3

Lu YY, Xu ZJ, Li HL, Tang JR, Chen XY (2021) The influences of super-critical CO2 saturation on tensile characteristics and failure modes of shales. Energy 221:119824. https://doi.org/10.1016/j.energy.2021.119824

McDaniel BW, Grundmann SR, Kendrick WD, Wilson DR, Jordan SW (1998) Field applications of cryogenic nitrogen as a hydraulic-fracturing fluid. J Petrol Technol 50:38–39

Michot A, Smith DS, Degot S, Gault C (2008) Thermal conductivity and specific heat of kaolinite: evolution with thermal treatment. J Eur Ceram Soc 28:2639–2644. https://doi.org/10.1016/j.jeurceramsoc.2008.04.007

Middleton R, Viswanathan H, Currier R, Gupta R (2014) CO2 as a fracturing fluid: potential for commercial-scale shale gas production and CO2 sequestration. Enrgy Proced 63:7780–7784. https://doi.org/10.1016/j.egypro.2014.11.812

Nguyen TT, Waldmann D, Bui TQ (2019) Computational chemo-thermo-mechanical coupling phase-field model for complex fracture induced by early-age shrinkage and hydration heat in cement-based materials. Comput Method Appl M 348:1–28. https://doi.org/10.1016/j.cma.2019.01.012

Ohtsu M, Okamoto T, Yuyama S (1998) Moment tensor analysis of acoustic emission for cracking mechanisms in concrete. Aci Struct J 95:87–95

Pan RK, Cheng YP, Yuan L, Yu MG, Dong J (2014) Effect of bedding structural diversity of coal on permeability evolution and gas disasters control with coal mining. Nat Hazards 73:531–546. https://doi.org/10.1007/s11069-014-1086-7

Pelak AJ, Sharma S (2014) Surface water geochemical and isotopic variations in an area of accelerating Marcellus Shale gas development. Environ Pollut 195:91–100. https://doi.org/10.1016/j.envpol.2014.08.016

Qin L, Wang P, Li SG, Lin HF, Wang RZ, Wang P, Ma C (2021) Gas adsorption capacity changes in coals of different ranks after liquid nitrogen freezing. Fuel 292:120404

Qin L, Ma C, Li SG, Lin HF, Wang P, Long H, Yan DJ (2022) Mechanical damage mechanism of frozen coal subjected to liquid nitrogen freezing. Fuel 309:122124

Ren S, Fan Z, Zhang L (2013) Mechanisms and experimental study of thermal-shock effect on coal-rock using liquid nitrogen. Chin J Rock Mech Eng 32:3790–3794 (in Chinese)

Sin P, Veinthal R, Sergejev F, Antonov M, Stubna I (2012) Fracture toughness of ceramics fired at different temperatures. Mater Sci Medzg 18:90–92. https://doi.org/10.5755/j01.ms.18.1.1349

Su SJ, Gao F, Cai CZ, Du ML, Wang ZK (2020) Experimental study on coal permeability and cracking characteristics under LN2 freeze-thaw cycles. J Nat Gas Sci Eng 83:103526. https://doi.org/10.1016/j.jngse.2020.103526

Su SJ, Hou P, Gao F, Liang X, Ding RY, Cai CZ (2022) Changes in mechanical properties and fracture behaviors of heated marble subjected to liquid nitrogen cooling. Eng Fract Mech 261:108256

Tang SB, Zhang H, Tang CA, Liu HY (2016) Numerical model for the cracking behavior of heterogeneous brittle solids subjected to thermal shock. Int J Solids Struct 80:520–531. https://doi.org/10.1016/j.ijsolstr.2015.10.012

Tenner TJ, Lange RA, Downs RT (2007) The albite fusion curve re-examined: new experiments and the high-pressure density and compressibility of high albite and NaAlSi3O8 liquid. Am Mineral 92:1573–1585. https://doi.org/10.2138/am.2007.2464

Wang MR, Wang JK, Pan N, Chen SY (2007) Mesoscopic predictions of the effective thermal conductivity for microscale random porous media. Phys Rev E 75:036702. https://doi.org/10.1103/PhysRevE.75.036702

Wang YT, Zhou XP, Kou MM (2018) Peridynamic investigation on thermal fracturing behavior of ceramic nuclear fuel pellets under power cycles. Ceram Int 44:11512–11542. https://doi.org/10.1016/j.ceramint.2018.03.214

Wang T, Ye X, Liu ZL, Liu XM, Chu DY, Zhuang Z (2020) A phase-field model of thermo-elastic coupled brittle fracture with explicit time integration. Comput Mech 65:1305–1321. https://doi.org/10.1007/s00466-020-01820-6

Wu XG, Huang ZW, Li R, Zhang SK, Wen HT, Huang PP, Dai XW, Zhang C (2018) Investigation on the damage of high-temperature shale subjected to liquid nitrogen cooling. J Nat Gas Sci Eng 57:284–294. https://doi.org/10.1016/j.jngse.2018.07.005

Wu XG, Huang ZW, Zhang SK, Cheng Z, Li R, Song HY, Wen HT, Huang PP (2019) Damage analysis of high-temperature rocks subjected to LN2 thermal shock. Rock Mech Rock Eng 52:2585–2603. https://doi.org/10.1007/s00603-018-1711-y

Yan H, Tian LP, Feng RM, Mitri H, Chen JZ, He K, Zhang Y, Yang SC, Xu ZJ (2020a) Liquid nitrogen waterless fracking for the environmental protection of arid areas during unconventional resource extraction. Sci Total Environ 721:137719. https://doi.org/10.1016/j.scitotenv.2020.137719

Yan H, Tian LP, Feng RM, Mitri H, Chen JZ, Zhang B (2020b) Fracture evolution in coalbed methane reservoirs subjected to liquid nitrogen thermal shocking. J Cent South Univ 27:1846–1860. https://doi.org/10.1007/s11771-020-4412-0

Zhai C, Qin L, Liu SM, Xu JZ, Tang ZQ, Wu SL (2016) Pore structure in coal: pore evolution after cryogenic freezing with cyclic liquid nitrogen injection and its implication on coalbed methane extraction. Energy and Fuel 30:6009–6020. https://doi.org/10.1021/acs.energyfuels.6b00920

Acknowledgements

This work had been financially supported by the National Natural Science Foundation of China (51604263, U1762105, and 51904270), the China Postdoctoral Science Foundation (2020M673451), the China University of Mining and Technology [3021802, The Fluidization Mining for Deep Coal Resources], and the Natural Science Foundation of Jiangsu Province (BK20160252).

Author information

Authors and Affiliations

Contributions

PH, SS and FG conceived and designed the study. PH performed the numerical simulations and wrote the manuscript. SS, XL and SW carried out the experiment. SS and YG analyzed the experimental results. FG and CC edited this manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hou, P., Su, S., Gao, F. et al. Influence of Liquid Nitrogen Cooling State on Mechanical Properties and Fracture Characteristics of Coal. Rock Mech Rock Eng 55, 3817–3836 (2022). https://doi.org/10.1007/s00603-022-02851-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02851-6