Abstract

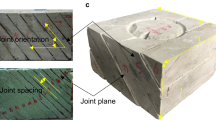

Cutter spacing is one of the important mechanical parameters that influence the cutting efficiency of tunnel boring machines (TBMs). A methodology was developed to optimize the cutter-spacing for efficient mechanical breaking, which improves the cutting efficiency of the jointed rock mass. In the beginning, 18 indentation tests were carried out on jointed granite specimens by varying cutter spacing, joint spacing, and joint set orientation, respectively. The cracking process of the jointed rock mass was captured by using a digital imaging correlation system clubbed with high-speed photography in real-time. Experimental results indicate that the joint plane facilitates horizontal displacement of the jointed rock mass, which causes more shear cracks develop across the joints. As a result, the efficiency of mechanical rock breaking of jointed rock mass becomes increases. Subsequently, a new term called crack propagation specific energy was proposed to determine the optimal cutter spacing, referring to the consumed energy per unit crack length. The optimal cutter spacing can be obtained from the limited experimental data based on crack propagation specific energy. It was found that the optimal ratio of cutter spacing to penetration depth s/p is 10. In addition, the horizontal displacement of jointed rock mass under the disc cutter favors the development of shear cracks, causing the increase of the optimal cutting spacing. The present investigation provides insights into the cutter design in jointed rock mass conditions, thereby making it possible for designers to adjust their design to enhance the TBM cutting efficiency.

Highlights

-

Propose the specific energy of crack growth to determine the best cutter spacing.

-

The joint plane facilitates horizontal displacement of the jointed rock mass.

-

More shear cracks appear at the joints of jointed rocks.

-

The optimal ratio of cutter spacing to penetration depth is determined.

Similar content being viewed by others

References

Bejari H, Hamidi JK (2013) Simultaneous effects of joint spacing and orientation on TBM cutting efficiency in jointed rock masses. Rock Mech Rock Eng 46:897–907. https://doi.org/10.1007/s00603-012-0314-2

Borri-Brunetto M, Carpinteri A, Invernizzi S (2003) Characterization and mechanical modeling of the abrasion properties of sintered tools with embedded hard particles. Wear 254:635–644. https://doi.org/10.1016/S0043-1648(03)00254-0

Carpinteri A, Invernizzi S (2005) Numerical analysis of the cutting interaction between indenters acting on disordered materials. Int J Fract 131:143–154. https://doi.org/10.1007/s10704-004-3635-7

Eftekhari M, Baghbanan A, Bagherpour R (2014) The effect of fracture patterns on penetration rate of TBM in fractured rock mass using probabilistic numerical approach. Arab J Geosci 7:5321–5331. https://doi.org/10.1007/s12517-013-1070-7

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado red granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44:238–246. https://doi.org/10.1016/j.ijrmms.2006.07.007

Gong QM, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46:8–18. https://doi.org/10.1016/j.ijrmms.2008.03.003

Gong QM, Zhao J, Jiao YY (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Sp Technol 20:183–191. https://doi.org/10.1016/j.tust.2004.08.006

Gong QM, Jiao YY, Zhao J (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Sp Technol 21:46–55. https://doi.org/10.1016/j.tust.2005.06.004

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Sp Technol 26:595–603. https://doi.org/10.1016/j.tust.2011.04.004

Howarth DF (1981) The effect of jointed and fissured rock on the performance of tunnel boring machines. ISRM Int Symp IS 1981:1069–1074

Jiang M, Liao Y, Wang H, Sun Y (2018) Distinct element method analysis of jointed rock fragmentation induced by TBM cutting. Eur J Environ Civ Eng 22:s79–s98. https://doi.org/10.1080/19648189.2017.1385540

Lin Q, Cao P, Li K et al (2018) Experimental study on acoustic emission characteristics of jointed rock mass by double disc cutter. J Cent S Univ 25:357–367. https://doi.org/10.1007/s11771-018-3742-7

Liu J, Cao P, Han D (2016) The influence of confining stress on optimum spacing of TBM cutters for cutting granite. Int J Rock Mech Min Sci 88:165–174. https://doi.org/10.1016/j.ijrmms.2016.07.017

Liu B, Yang H, Haque E, Wang G (2021) Effect of joint orientation on the breakage behavior of jointed rock mass loaded by disc cutters. Rock Mech Rock Eng 54:2087–2108. https://doi.org/10.1007/s00603-021-02379-1

Macias FJ, Dahl F, Bruland A (2016) New rock abrasivity test method for tool life assessments on hard rock tunnel boring: the rolling indentation abrasion test (RIAT). Rock Mech Rock Eng 49:1679–1693. https://doi.org/10.1007/s00603-015-0854-3

Moon T, Oh J (2012) A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech Rock Eng 45:837–849. https://doi.org/10.1007/s00603-011-0180-3

Nelson PP, Ingraffea AR, Orourke TD (1985) TBM performance prediction using rock fracture parameters. Int J Rock Mech Min Sci 22:189–192. https://doi.org/10.1016/0148-9062(85)93234-6

Rosutami J (1993) A new model for performance prediction of hard rock TBMs. In: Proceedings/1993 rapid excavation and tunneling conference

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci 12:361–366. https://doi.org/10.1016/0148-9062(75)90547-1

Snowdon RA, Ryley MD, Temporal J (1982) A study of disc cutting in selected British rocks. Int J Rock Mech Min Sci 19:107–121. https://doi.org/10.1016/0148-9062(82)91151-2

Sun J, Chen M, Chen B, Lu W (2011) Numerical simulation of influence factors for rock fragmentation by TBM cutters. J Geotech Mech 32:1891–1897

Teale R (1965) The concept of specific energy in rock drilling. Int J Rock Mech Min Sci 2:57–73. https://doi.org/10.1016/0148-9062(65)90022-7

Wanner H, Aeberli U (1979) Tunnelling machine performance in jointed rock. In: Proceedings of 4th Congress of the International Society for Rock Mechanics, vol 1, Montreux, Switzerland, September 1979, pp 573–580

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22:808–814. https://doi.org/10.1016/j.engappai.2009.03.007

Yang HQ, Li Z, Jie TQ, Zhang ZQ (2018) Effects of joints on the cutting behavior of disc cutter running on the jointed rock mass. Tunn Undergr Sp Technol 81:112–120. https://doi.org/10.1016/j.tust.2018.07.023

Yang H, Liu B, Karekal S (2021) Experimental investigation on infrared radiation features of fracturing process in jointed rock under concentrated load. Int J Rock Mech Min Sci 139:104619. https://doi.org/10.1016/j.ijrmms.2021.104619

Yin L, Miao C, He G et al (2016) Study on the influence of joint spacing on rock fragmentation under TBM cutter by linear cutting test. Tunn Undergr Sp Technol 57:137–144. https://doi.org/10.1016/j.tust.2016.02.018

Acknowledgements

The financial support from Natural Science Fund of China (No. 51879016) and Project supported by graduate research and innovation foundation of Chongqing, China (Grant No. CYB21032) are greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known completing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, K., Yang, H., Xie, J. et al. An Optimization Methodology of Cutter-Spacing for Efficient Mechanical Breaking of Jointed Rock Mass. Rock Mech Rock Eng 55, 3301–3316 (2022). https://doi.org/10.1007/s00603-022-02806-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02806-x