Abstract

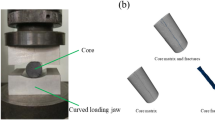

We investigate the evolution of` fracture conductivity as a function of proppant loading concentration under varying effective stresses as an analog to reservoir drawdown. In particular, we define the relative impacts and interactions between proppant crushing, proppant embedment, compaction and particle rearrangement and their impacts on fluid transport. Proppant of realistic concentrations is sandwiched between split core-plugs of Marcellus shale that accommodates embedment as well as rigid steel that excludes it. Impacts of proppant crushing and embedment and roles of particulate transport in fracturing-fluid clean-up are defined. Experiments are performed under triaxial stresses with independent control on confining stress and pore pressure. Normal loading is incremented to represent reservoir drawdown with conductivity evolution recorded continuously via flow-through of brine (20,000 mg/L KCl). Proppant embedment is characterized pre- and post-test by white light optical profilometry with pre-and post-test particle size distributions of the proppant defining the impact of proppant crushing. The conductivity of propped fractures decreases by up to 95% as effective stress is increased by 50 MPa (7000 \(\mathrm{psi})\). This reduction is broadly independent of whether the fracture walls are rigid or deformable. The stress-sensitivity of conductivity is generally muted with increasing proppant loading concentration. We normalize fracture conductivities to equivalent permeabilities of the proppant pack to directly compare pack permeabilities. Low proppant concentrations return higher permeability at low effective stresses but lower permeability at high effective stress, relative to high proppant concentrations. This results since proppant crushing and embedment are both mitigated with increasing proppant loading concentration, as more displacement degree of freedom are added to the system and provide accommodation for interior compaction and rearrangement. Extended effective stress holding times (24 h vs < 1 h) and proppant “aging” exert little impact on transient changes in fracture conductivity.

Highlights

-

Propped shale fracture conductivity decreases as the effective pressure increases. Stress sensitivity reduces with increasing effective stress.

-

Reduced proppant loading concentration results in greater proppant embedment, increased proppant crushing and greater circularity.

-

The mechanisms for permeability reduction between different proppant loading concentrations (thicknesses) are different.

-

Where proppants are injected at low loading concentrations, the most effective approach to maintain permeability is to reduce proppant embedment.

-

Where high proppant loading concentrations are attained, the major impairment mechanism is proppant compaction and rearrangement.

Similar content being viewed by others

References

Alramahi B, Sundberg MI (2012) Proppant embedment and conductivity of hydraulic fractures in shales. In: 46th US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association, 2012.

Arthur JD, Bohm B, Layne M (2009) Hydraulic fracturing considerations for natural gas wells of the Marcellus Shale.

Barree RD et al (2003) Realistic assessment of proppant pack conductivity for material selection. In: SPE Annual Technical Conference and Exhibition. OnePetro, 2003

Beckwith R (2011) Proppants: where in the world. J Petrol Technol 63(04):36–41

Berrezueta E et al (2019) Representativity of 2D shape parameters for mineral particles in quantitative petrography. Minerals 9(12):768

Briggs K et al (2014) The relationship between rock properties and fracture conductivity in the Fayetteville shale. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, 2014

Chen X et al (2018) Pore-scale determination of gas relative permeability in hydrate-bearing sediments using X-ray computed micro-tomography and lattice Boltzmann method. Water Resour Res 54(1):600–608

Cikes M (1996) Long-term hydraulic fracture conductivities under extreme conditions. In: European Petroleum Conference. Society of Petroleum Engineers, 1996

Costa A (2006) Permeability-porosity relationship: a reexamination of the Kozeny-Carman equation based on a fractal pore-space geometry assumption. Geophys Res Lett 33(2). https://doi.org/10.1029/2005GL025134

Elsarawy AM, Nasr-El-Din HA (2018) Proppant performance in marcellus shale fractures under experimental in-situ stress conditions. In: SPE/IADC Middle East Drilling Technology Conference and Exhibition. Society of Petroleum Engineers, 2018.

Foust AS et al (2008) Principles of unit operations. Wiley

Han D et al (2019) Analysis of the Kozeny-Carman model based on pore networks. J Geophys Eng 16(6):1191–1199

Koteeswaran S et al (2018) Characterization of shale–fluid interaction through a series of immersion tests and rheological studies. J Pet Explor Prod Technol 8(4):1273–1286

Kruczek B (2014) Carman–kozeny equation. Encyclopedia of membranes, pp 1–3.

Kurz BA, Schmidt DD, Cortese PE (2013) Investigation of improved conductivity and proppant applications in the Bakken formation. In: SPE Hydraulic Fracturing Technology Conference. Society of Petroleum Engineers, 2013

Lee DS et al (2010) Experiment and modeling to evaluate the effects of proppant-pack diagenesis on fracture treatments. J Pet Sci Eng 74(1–2):67–76

Liang F et al (2016) A comprehensive review on proppant technologies. Petroleum 2(1):26–39

Mayerhofer MJ, et al (2006) Integration of microseismic-fracture-mapping results with numerical fracture network production modeling in the Barnett Shale. In: SPE annual technical conference and exhibition. OnePetro, 2006

Meyers RA (1982) The macromolecular structure of coal: coal structure. Academic Press Inc., New York, p 250

Ming CHEN et al (2018) Calculation method of proppant embedment depth in hydraulic fracturing. Pet Explor Dev 45(1):159–166

Mittal A, Rai CS, Sondergeld CH (2018) Proppant-conductivity testing under simulated reservoir conditions: impact of crushing, embedment, and diagenesis on long-term production in shales. SPE J 23(04):1–304

Palisch TT, et al (2007) Determining realistic fracture conductivity and understanding its impact on well performance-theory and field examples. In: SPE Hydraulic Fracturing Technology Conference. Society of Petroleum Engineers, 2007

Pope C et al (2009) Haynesville shale-one operator's approach to well completions in this evolving play. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, 2009.

Terracina JM, et al (2010) Proppant selection and its effect on the results of fracturing treatments performed in shale formations. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, 2010

Vengosh A et al (2014) A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States. Environ Sci Technol 48(15):8334–8348

Wang J, Elsworth D (2018) Role of proppant distribution on the evolution of hydraulic fracture conductivity. J Pet Sci Eng 166:249–262. https://doi.org/10.1016/j.petrol.2018.03.040

Weaver JD et al (2007) Fracture-related diagenesis may impact conductivity. SPE J 12(03):272–281

Wen Q et al (2007) The effect of proppant embedment upon the long-term conductivity of fractures. J Pet Sci Eng 55(3–4):221–227

Yasuhara H, Elsworth D, Polak A (2003) A mechanistic model for compaction of granular aggregates moderated by pressure solution. J Geophys Res Solid Earth 108(B11)

Zhang J et al (2013) Laboratory measurement of hydraulic fracture conductivities in the Barnett shale. In: IPTC 2013: International Petroleum Technology Conference. European Association of Geoscientists & Engineers, 2013

Zhang F et al (2017) Discrete-element-method/computational-fluid-dynamics coupling simulation of proppant embedment and fracture conductivity after hydraulic fracturing. Spe J 22(02):632–644

Zhang J, Zhu D, Hill AD (2015 February) Water-induced fracture conductivity damage in shale formations. In SPE Hydraulic Fracturing Technology Conference. OnePetro.

Zheng W, Tannant D (2016) Frac sand crushing characteristics and morphology changes under high compressive stress and implications for sand pack permeability. Can Geotech J 53(9):1412–1423

Acknowledgements

This work was supported by Chevron ETC. This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, J., Wang, J., Wang, S. et al. Conductivity Evolution in Propped Fractures During Reservoir Drawdown. Rock Mech Rock Eng 55, 3583–3597 (2022). https://doi.org/10.1007/s00603-022-02796-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-02796-w