Abstract

Energy principles, which can favorably explain the complete rock failure process, are one of the most reliable analysis approaches in rock mechanics and engineering. In this study, a strain energy approach under true triaxial compression (TTC) is proposed. On this basis, the energy evolution characteristics and variations of different failure behavior types (Class I, Class II and ductile failure) under TTC are analyzed. The variations of the strain energy characteristics of Beishan granite with σ2 and σ3 under TTC are studied. The results indicate that the total strain energy U and the elastic strain energy \(U^{e}\) of Beishan granite increase with the increasing σ2 or σ3. The dissipated strain energy \(U^{d}\) rapidly increases when the value of ε1/ε1peak is approximately 0.6–0.8. The influence of σ3 on the rock failure mode and energy evolution characteristics is greater than that of σ2. In highly brittle rocks, the tensile cracking of the rock microstructure is dominant, and the rock has a high strain energy storage capacity and a low strain energy dissipation capacity. The cumulative acoustic emission (AE) count rate curve shows the same trend as the total dissipated strain energy \(U^{d}\) curve. The research results show that the proposed strain energy analysis method for TTC can explain the macroscopic failure behaviors, microscopic failure mechanism and AE characteristics of Beishan granite under TTC, thereby providing new ideas and methods for investigating the behaviors of deep underground hard rock.

Similar content being viewed by others

Abbreviations

- \(\sigma_{1}\), \(\sigma_{2}\), and \(\sigma_{3}\) :

-

Maximum, intermediate, and minimum principal stresses

- \(\varepsilon_{1}\), \(\varepsilon_{2}\), and \(\varepsilon_{3}\) :

-

Maximum, intermediate, and minimum principal strains

- \(U\), \(U^{e}\), \(U^{d}\) :

-

Total strain energy, elastic strain energy, and dissipated strain energy per unit volume of rock

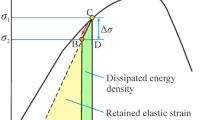

- \(A\), \(B\) and \(C\) :

-

\(\sigma_{3}\), \(\sigma_{2}\) loading phase end points and \(\sigma_{1}\) peak point

- \(\sigma_{A}\), \(\sigma_{B}\) and \(\sigma_{C}\) :

-

Stresses corresponding to points A, B and C

- \(\varepsilon_{A}^{t}\) and \(\varepsilon_{B}^{t}\) :

-

Strains corresponding to points A and B

- \(\varepsilon_{1}^{{t{\text{c}}}}\), \(\varepsilon_{2}^{{t{\text{c}}}}\) and \(\varepsilon_{3}^{{t{\text{c}}}}\) :

-

Peak strains corresponding to \(\sigma_{1}\), \(\sigma_{2}\), and \(\sigma_{3}\)

- \(n^{{}}\) and \(i^{{}}\) :

-

The numbers of small trapezoidal segments and segmentation points at any specific time t

- \(\varepsilon_{1}^{t}\), \(\varepsilon_{2}^{t}\) and \(\varepsilon_{3}^{t}\) :

-

Strains corresponding to \(\sigma_{1}\), \(\sigma_{2}\), and \(\sigma_{3}\) at any specific time t

- \(\varepsilon_{1}^{{{\text{e}}t}}\), \(\varepsilon_{2}^{et}\) and \(\varepsilon_{3}^{et}\) :

-

Elastic strains corresponding to \(\sigma_{1}\), \(\sigma_{2}\), and \(\sigma_{3}\) at any specific time t

- \(\varepsilon_{2}^{{e_{1} }}\) and \(\varepsilon_{2}^{{e_{2} }}\) :

-

Elastic strains corresponding to \(\sigma_{2}\) at point B and from point B to point C

- \(\varepsilon_{3}^{{e_{1} }}\), \(\varepsilon_{3}^{{e_{2} }}\) and \(\varepsilon_{3}^{{e_{2}^{'} }}\) :

-

Elastic strains corresponding to \(\sigma_{3}\) at point A, from point A to point B and from point A to point C

- \(\theta\) :

-

Failure angle between the failure plane and the \(\sigma_{1}\) loading surface

References

Abu Al-Rub RK, Voyiadjis GZ (2003) On the coupling of anisotropic damage and plasticity models for ductile materials. Int J Solids Struct 40(2):2611–2643

Ai C, Zhang J, Li YW, Zeng J, Yang XL, Wang JG (2016) Estimation criteria for rock brittleness based on energy analysis during the rupturing process. Rock Mech Rock Eng 49(12):4681–4698

Chen ZQ, He C, Wu D, Xu GW, Yang WB (2017) Fracture evolution and energy mechanism of deep-buried carbonaceous slate. Acta Geotech 12:1243–1260

Dong XJ, Karrech A, Basarir H, Elchalakani M, Seibi A (2018) Energy dissipation and storage in underground mining operations. Rock Mech Rock Eng 52:229–245

Feng XT, Hudson JA (2011) Rock engineering design. CRC, Oxford

Feng XT, Zhang XW, Kong R, Wang G (2016) A novel Mogi type true triaxial testing apparatus and its use to obtain complete stress-strain curves of hard rocks. Rock Mech Rock Eng 49(5):1649–1662

Feng XT, Zhang XW, Yang CX, Kong R, Liu XY, Peng S (2017) Evaluation and reduction of the end friction effect in true triaxial tests on hard rocks. Int J Rock Mech Min Sci 97:144–148

Gao YH, Feng XT, Zhang XW, Feng GL, Jiang Q, Qiu SL (2018) Characteristic Stress Levels and brittle fracturing of hard rocks subjected to true triaxial compression with low minimum principal stress. Rock Mech Rock Eng 51:3681–3697

Gaziev E (2001) Rupture energy evaluation for brittle materials. Int J Solids Struct 38(42):7681–7690

Hua AZ, You MQ (2013) Rock failure due to energy release during unloading and application to underground rock burst control. Tunn Undergr Sp Technol 23(8):1572–1578

Huang D, Li YR (2014) Conversion of strain energy in triaxial unloading tests on marble. Int J Rock Mech Min Sci 66:160–168

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics, 4th edn. Wiley-Blackwell, Oxford

Kanaya T, Hirth G (2018) Brittle to semibrittle transition in quartz sandstone: energetics. J Geophys Res Solid Earth 123:84–106

Kong R, Feng XT, Zhang XW, Yang CX (2018) Study on crack initiation and damage stress in sandstone under true triaxial compression. Int J Rock Mech Min Sci 106:117–123

Li QM (2001) Strain energy density failure criterion. Int J Solids Struct 38:6997–7013

Li DY, Sun Z, Xie T, Li XB, Ranjith PG (2017) Energy evolution characteristics of hard rock during triaxial failure with different loading and unloading paths. Eng Geol 228:270–281

Meng QB, Zhang MW, Han LJ, Pu H, Nie TY (2016) Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech Rock Eng 49:3873–3886

Ning JG, Wang J, Jiang JQ, Hu SC, Jiang LS, Lu XS (2018) Estimation of crack initiation and propagation thresholds of confined brittle coal specimens based on energy dissipation theory. Rock Mech Rock Eng 51:119–134

Peng RD, Ju Y, Wang JG, Xie HP, Gao F, Mao LT (2015) Energy dissipation and release during coal failure under conventional triaxial compression. Rock Mech Rock Eng 48(2):509–526

Solecki R, Conant RJ (2003) Advanced mechanics of materials. Oxford University Press, London

Su GS, Feng XT, Jiang Q, Chen GQ (2006) Study on new index of local energy release rate for stability analysis and optimal design of underground rock mass engineering with high geostress. Chin J Rock Mech Eng 25(12):2453–2460 (in Chinese)

Tarasov BG, Potvin Y (2013) Universal criteria for rock brittleness estimation under triaxial compression. Int J Rock Mech Min Sci 59(4):57–69

Tarasov BG, Randolph MF (2011) Superbrittleness of rocks and earthquake activity. Int J Rock Mech Min Sci 48:888–898

Tarasov BG, Stacey TR (2017) Features of the energy balance and fragmentation mechanisms at spontaneous failure of Class I and Class II rocks. Rock Mech Rock Eng 50(10):2563–2584

Wang JA, Park HD (2001) Comprehensive prediction of rockburst based on analysis of strain energy in rocks. Tunn Undergr Sp Technol 16(1):49–57

Xie HP, Ju Y, Li LY (2005) Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng 24(17):3003–3010 (in Chinese)

Xie HP, Li LY, Peng RD, Ju Y (2009) Energy analysis and criteria for structural failure of rocks. J Rock Mech Geotech Eng 1:11–20

Zhang Y, Feng XT, Yang CX, Zhang XW, Sharifzadeh M, Wang ZF (2019) Fracturing evolution analysis of Beishan granite under true triaxial compression based on acoustic emission and strain energy. Int J Rock Mech Min Sci 117:150–161

Zhao XG, Cai M, Wang J, Ma LK (2013) Damage stress and acoustic emission characteristics of the Beishan granite. Int J Rock Mech Min Sci 64:258–269

Zhao J, Feng XT, Zhang XW, Zhang Y, Zhou YY, Yang CX (2018) Brittle-ductile transition and failure mechanism of Jinping marble under true triaxial compression. Eng Geol 232:160–170

Acknowledgements

We sincerely acknowledge the financial support from the National Natural Science Foundation of China (Grant nos. 51621006, 51579043 and 51709043). The authors are grateful to Mr. Yangyi Zhou, Mr. Gaolei Song, Mr. Rui Kong, Mr. Jun Zhao, Mr. Qiang Han, Mr. Hong Xu and Mr. Yuemao Zhao at Northeastern University, China and Mr. Yaohui Gao and Mr. Zhi Zheng at the Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, for their valuable academic discussions and generous assistance with the laboratory tests. The authors would also like to thank the journal editor and anonymous reviewers for their valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Feng, XT., Zhang, X. et al. A Novel Application of Strain Energy for Fracturing Process Analysis of Hard Rock Under True Triaxial Compression. Rock Mech Rock Eng 52, 4257–4272 (2019). https://doi.org/10.1007/s00603-019-01868-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01868-8