Abstract

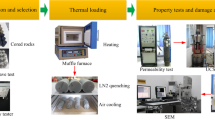

Thermal spallation may be economically advantageous for the drilling of deep wells and is of strong interest for the development of oil, gas and geothermal energy. The lowest required surface temperature (LRST) represents the minimal surface temperature that can induce the spallation of rock. A deeper understanding of the LRST can be used to determine when thermal spallation can be successfully initiated. However, to the best of our knowledge, comparisons of LRST in sandstone and granite have not been performed. Based on experiments and simulations, this study investigated the LRST of one type of granite and one type of sandstone in thermal spallation. First, we conducted thermal spallation experiments using rock specimens and measured the LRST by an infrared thermometer. Then, the heat flux was evaluated and compared between the sandstone and granite specimens. Meanwhile, a three-dimensional numerical model was built to simulate the heat transfer and stress distribution in the granite and sandstone specimens. The temperature and von Mises stress between the granite and sandstone specimens were compared, and then the breakage-probability factors were investigated to compare the experimental results and simulation results. This study clarifies the differences in LRST between one type of granite and one type of sandstone.

Similar content being viewed by others

Abbreviations

- LRST:

-

Lowest required surface temperature

- A :

-

Slope of “best-fit” line (K/s1/2)

- C :

-

Heat capacity (J/(kg•K))

- \({f_{\text{b}}}\) :

-

Breakage-probability factor (dimensionless)

- \(E\) :

-

Young’s modulus (Pa)

- \({F_i}\) :

-

Body force (Pa)

- \(G\) :

-

Shear modulus (Pa)

- \({h_{\text{f}}}\) :

-

Heat convective coefficient [(W/(m2 K)]

- \({K_{\text{r}}}\) :

-

Thermal conductivity coefficient [W/(m K)]

- \(K^{\prime}\) :

-

Rock expansion index (Pa)

- \(Q\) :

-

Heat flux on the rock surface (W/m2)

- \({Q_0}\) :

-

Convective heat transfer coefficient (W/m2)

- \(T\) :

-

Temperature in the rock (K)

- \({T_{\text{b}}}\) :

-

Temperature on the boundary (K)

- \({T_{{\text{ext}}}}\) :

-

Temperature of ambient temperature (K)

- \(u\) :

-

Displacement (m)

- \(\alpha\) :

-

Rock thermal diffusivity (m2/s)

- \(\beta\) :

-

Thermal expansion coefficient (/K)

- \(\mu\) :

-

Poisson’s ratio (–)

- \({\varepsilon _{ij}}\) :

-

Strain tensor (dimensionless)

- \(\rho\) :

-

Rock density (kg/m3)

- \({\sigma _{ij,j}}\) :

-

Stress tensor (Pa)

- \({\sigma _{\text{s}}}\) :

-

Yield strength (Pa)

- \({\sigma _{\text{v}}}\) :

-

Von Mises stress (Pa)

- \({\sigma _1}\) :

-

First principal stress (Pa)

- \({\sigma _{\text{2}}}\) :

-

Second principal stress (Pa)

- \({\sigma _{\text{3}}}\) :

-

Third principal stress (Pa)

References

Augustine CR (2009) Hydrothermal spallation drilling and advanced energy conversion technologies for engineered geothermal systems, Ph.D. thesis, Massachusetts Institute of Technology, Massachusetts

Beentjes I, Bender JT, Hillson SD.,Tester JW (2018) Hydrothermal spallation of barre granite using supercritical water jets. Proceedings, 43rd workshop on Geothermal Reservoir Engineering Stanford University, Stanford, California

Brkic D, Kant M, Meier T, Schuler MJ, Rohr R (2015) Influence of process parameters on thermal rock fracturing under ambient conditions. Proceedings World Geothermal Congress 2015. Melbourne, Australia

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. Oxford University Press, Oxford

Dey TN (1984) More on spallation theory. In: Los Alamos National Laboratory Internal Memorandum No. E55-3-286-84

Dey TN, Kranz RL (1987) Flake mechanics, borehole breakouts, and thermal spallation. In: Proceedings of the 28th US symposium on rock mechanics, Tucson, Arizona

Hettema M, Wolf KH, Pater CD (1998) The influence of steam pressure on thermal spalling of sedimentary rock: theory and experiments. Int J Rock Mech Min Sci 35(1):3–15

Hu X, Song X, Li G, Shen Z, Cui L, Lv Z, Shi Y (2016) Numerical analysis of bottomhole velocity and pressure distributions of high pressure high temperature hydrothermal jet. In: SPE/IADC Asia Pacific Drilling Technology Conference, Singapore

Hu X, Song X, Li G, Shen Z, Lyu Z, Shi Y (2018a) Shape factor of the flake-like particle in thermal spallation and its effects on settling and transport behavior in drilling annulus. Powder Technol 335:211–221

Hu X, Song X, Li G, Shen Z, Lyu Z, Shi Y, Zheng R (2018b) An analytical model to evaluate the heating conditions for drilling in hard rock using an innovative hydrothermal spallation method. Appl Therm Eng 142:709–716

Kant MA, von Rohr PR (2016) Minimal required boundary conditions for the thermal spallation process of granitic rocks. Int J Rock Mech Min Sci 84:177–186

Lyu Z, Song X, Shi Y, Li G, Hu X, Zheng R, Wang G (2017) Analysis on feasibility of rock thermal spallation drilling utilizing specific energy method. American Rock Mechanics Association, San Francisco

Potter RM, Potter JM, Wideman TW (2010) Laboratory study and field demonstration of hydrothermal spallation drilling. GRC Trans 34:249–252

Preston FW, White HE (1934) Observations on spalling. J Am Ceram Soc 17:137–144

Rauenzahn RM (1986) Analysis of rock mechanics and gas dynamics of flame-jet thermal spallation drilling. Ph.D. thesis, Massachusetts Institute of Technology, Massachusetts

Rauenzahn R, Tester J (1989) Rock failure mechanisms of flame-jet thermal spallation drilling-theory and experimental testing. Int J Rock Mech Min Sci Geomech Abst 26(5):381–399

Rauenzahn RM, Tester JW (1991a) Numerical simulation and field testing of flame-jet thermal spallation drilling-1. Model development. Int J Heat Mass Trans 34(3):795–808

Rauenzahn RM, Tester JW (1991b) Numerical simulation and field testing of flame-jet thermal spallation drilling-2. Experimental verification. Int J Heat Mass Trans 34(3):809–818

Rothenfluh T (2013) Heat transfer phenomena of supercritical water jets in hydrothermal spallation drilling, Ph.D. thesis, Swiss Federal Institute of Technology, Zurich

Rothenfluh T, Schuler MJ, Rohr PR (2011) Penetration length studies of supercritical water jets submerged in a subcritical water environment using a novel optical Schlieren method. J Supercrit Fluids 57:175–182

Sierra-Pallares J, Parra-Santos MT, García-Serna J, Castro F, Cocero MJ (2009) Numerical modeling of hydrothermal flames. Micromixing effects over turbulent reaction rates. J Supercrit Fluids 50(2):146–154

Song X, Lv Z, Li G, Hu X, Shi Y (2017) Numerical analysis on the impact of the flow field of hydrothermal jet drilling for geothermal wells in a confined cooling environment. Geothermics 66:39–49

Stacey RW, Sanyal S, Potter J, Wideman T (2011) Effectiveness of selective borehole enlargement to improve flow performance of geothermal wells. GRC Trans 35:239–245

Walsh SDC (2013) Modeling thermally induced failure of brittle geomaterials. Technical Report No. LLNL-TR-632239, Lawrence Livermore National Laboratory (LLNL), Livermore, CA

Walsh SDC, Lomov IN (2013) Micromechanical modeling of thermal spallation in granitic rock. Int J Heat Mass Trans 65:366–373

Walsh SDC, Lomov I, Roberts JJ (2011) Geomechanical modeling for thermal spallation drilling. LLNL-PROC-483098. In: Geothermal Resources Council 35th Annual Meeting, San Diego, CA, United States

Walsh SDC, Lomov IIya N, Wideman TW, Potter JM (2014) Size-dependent spall aspect ratio and its effects in thermal spallation. Int J Rock Mech Min Sci 70:375–380

Wilkinson MA, Tester JW (1993) Experimental measurement of surface temperatures during flame-jet induced thermal spallation. Rock Mech Rock Eng 26(1):29–62

Williams RE, Potter RM, Miska S (1996) Experiments in thermal spallation of various rocks. Transactions of the ASME 118:2–8

Zhou J, Wei J, Yang T, Zhu W, Li L, Zhang P (2018) Damage analysis of rock mass coupling joints, water and microseismicity. Tunn Undergr Sp Tech 71:366–381

Zhu W, Tang C (2004) Micromechanical model for simulating the fracture process of rock. Rock Mech Rock Eng 37(1):25–56

Zhu W, Wei J, Zhao J, Niu L (2014) 2D numerical simulation on excavation damaged zone induced by dynamic stress redistribution. Tunn Undergr Sp Tech 43:315–326

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (no. U1562212 and no. 51504272) and National Key Research and Development Program of China (2016YFE0124600).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, X., Song, X., Liu, Y. et al. Lowest Required Surface Temperature for Thermal Spallation in Granite and Sandstone Specimens: Experiments and Simulations. Rock Mech Rock Eng 52, 1689–1703 (2019). https://doi.org/10.1007/s00603-018-1665-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1665-0