Abstract

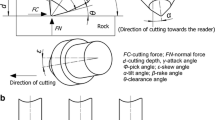

Specific energy is one of the most significant parameters in the process of rock cutting and it has been widely used for evaluating the performance of excavation machines. In this paper, based on rock cutting tests that were conducted on a linear cutting machine (LCM), the effects of relevant cutting parameters and characteristics, including the clearance angle, the cone (tip) angle of conical picks, the rake angle and the cutting depth on specific energy were investigated. Five different conical picks with the cone angles between 60° and 100° were used in the experiments. In addition, five different sandstones with uniaxial compressive strength varying from 17.91 to 85.98 MPa were subjected to cutting tests under different levels of cutting parameters. As a result of the tests, it was found that the clearance angle has a considerable effect on cutting force and specific energy. When it was greater than 10°, mean cutting force increased with the increasing cone angle, yet linearly decreased with the increasing rake angle and attack angle. However, specific energy has no statistical relationship with the attack angle, the rake angle, and the cone angle. It does not vary effectively with the relevant angles. Statistical analyses also indicate that strong relationships exist between the specific energy and the cutting depth in a power function. In this context, a general model of specific energy was proposed, and based on the test data and previous studies, empirical models of specific energy were developed using multiple non-linear regression and principal component regression methods. Besides, the statistical analyses showed a good agreement between the measured and predicted specific energy in unrelieved and relieved cutting modes. In conclusion, some prediction models of roadheader production rates were developed that were based on the models of specific energy. By comparing the results with the literature, it was found that the proposed models are valid in predicting the instantaneous cutting rate of roadheader especially at the cutting depth of 7–9 mm. They can be used for preliminary estimation of the production rate of roadheaders. Thus, it can be claimed that the models can offer effective solutions for the prediction of production rate of roadheaders equipped with conical picks.

Similar content being viewed by others

Abbreviations

- d :

-

Depth of cut (mm)

- FC:

-

Cutting force

- FN:

-

Normal force

- FCm :

-

Mean cutting force (N)

- ICR:

-

Instantaneous cutting rate (m3/h)

- k :

-

Energy transfer ratio

- k opt :

-

Ratio of specific energy in relieved to unrelieved cutting mode

- L :

-

Cutting distance (m)

- M :

-

Mass of rock chips (kg)

- P :

-

Cutting power of the cutting head (kW)

- R σ :

-

Coefficient representing rock strength parameters

- SE:

-

Specific energy (kWh/m3)

- SEu :

-

Specific energy in unrelieved mode

- SEopt :

-

Optimum specific energy in relieved mode

- σ c :

-

Uniaxial compressive strength of rock (MPa)

- σ t :

-

Tensile strength of rock (MPa)

- ρ :

-

Density of the rock (kg/m3)

- α :

-

Tilt angle

- β :

-

Rake angle

- γ :

-

Attack angle

- θ :

-

Clearance angle

- ϕ :

-

Cone angle of the pick

References

Avunduk E, Tumac D, Atalay AK (2014) Prediction of roadheader performance by artificial neural network. Tunn Undergr Space Technol 44:3–9

Balci C, Bilgin N (2007) Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines. Int J Rock Mech Min Sci 44:468–476

Balci C, Demircin MA, Copur H, Tuncdemir H (2004) Estimation of optimum specific energy based on rock properties for assessment of roadheader performance. J S Afr Inst Min Metall 104(11):633–642

Bilgin N, Seyrek T, Erdinc E, Shahriar K (1990) Roadheaders glean valuable tips for Istanbul Metro. Tunnels Tunnell October 29–32

Bilgin N, Dincer T, Copur H, Erdogan M (2004) Some geological and geotechnical factors affecting the performance of a roadheader in an inclined tunnel. Tunn Undergr Space Technol 19:629–636

Bilgin N, Dumac D, Feridunoglu C, Karakas AR, Akgul M (2005) The performance of a roadheader in high strength rock formations in Kücüksu tunnel. In: Proceedings of the 31st ITA-AITES World Tunnel Congress. Istanbul, pp 815–820

Bilgin N, Demircin MA, Copur H, Balci C, Tuncdemir H, Akcin N (2006) Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int J Rock Mech Min Sci 43:139–156

Bilgin N, Copur H, Balci C (2012) Effect of replacing disc cutters with chisel tools on performance of a TBM in difficult ground conditions. Tunn Undergr Space Technol 27:41–51

Bilgin N, Copur H, Balci C (2014) Mechanical excavation in mining and civil industries CRC Press, Boca Raton, p p366

Brown TT (ed) (1981) ISRM suggested methods. Rock characterization testing and monitoring. Pergamon Press, Oxford, 211 p ISRM

Cardu M, Iabichino G, Oreste P, Rispoli A (2017) Experimental and analytical studies of the parameters influencing the action of TBM disc tools in tunneling. Acta Geotech. https://doi.org/10.1007/s11440-016-0453-9

Comakli R, Kahraman S, Balci C (2014) Performance prediction of roadheaders in metallic ore excavation. Tunn Undergr Space Technol 40:38–45

Copur H, Bilgin N, Tuncdemir H, Balci C (2003) A set of indices based on indentation tests for assessment of rock cutting performance and rock properties. J S Afr Inst Min Metall 103(11):589–599

Copur H, Bilgin N, Balci C, Tumac D, Avunduk E (2017) Effects of different cutting patterns and experimental conditions on the performance of a conical drag tool. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-017-1172-8

Dursun AE, Gokay MK (2016) Cuttability assessment of selected rocks through different brittleness values. Rock Mech Rock Eng 49(4):1173–1190

Evans I (1984) A theory of the cutting force for point-attack picks. Int J Min Eng 2:63–71

Fowell RJ, Ochei NN (1984) A comparison of dust make and energy requirements for rock cutting tools. Int J Min Eng 2:73–83

Gehring KH (1989) Cutting comparison. Tunn Tunn Int 21(11): 27–30

Gunes N, Yurdakul M, Goktan RM (2007) Prediction of radial bit cutting force in high-strength rocks using multiple linear regression analysis. Int J Rock Mech Min Sci 44:962–970

Gunes N, Tumac D, Goktan RM (2014) Rock cuttability assessment using the concept of hybrid dynamic hardness (HDH). Bull Eng Geol Environ 74(4):1–12

He X, Xu C (2016) Specific energy as an index to identify the critical failure mode transition depth of rock cutting. Rock Mech Rock Eng 49(4):1461–1478

Hughes H (1972) Some aspects of rock machining. Int J Rock Mech Min Sci 9:205–211

Hurt KG, Evans I (1981) Point attack tools: an evaluation of function and use for rock cutting. Min Eng 140:673–675

Hurt KG, McAndrew KM (1985) Cutting efficiency and life of rock cutting picks. Min Sci Technol 2:139–151

Levenberg K (1944) A method for the solution of certain non-linear problems in least squares. J Heart Lung Transpl 2(4):436–438

Marquardt DW (1963) An algorithm for least square estimation of non-linear parameters. J Soc Ind Appl Math 11(2):431–441

Mellor M (1972) Normalization of specific energy values. Int J Rock Mech Min Sci 9:661–663

Nishimatsu Y (1972) The mechanics of the rock cutting. Int J Rock Mech Min Sci 9:261–270

Origliasso C, Cardu M, Kecojevic V (2014) Surface miners: evaluation of the production rate and cutting performance based on rock properties and specific energy. Rock Mech Rock Eng 47(2):757–770

Rostami J, Ozdemir L, Neil DM (1994) Performance prediction: a key issue in mechanical hard rock mining. Min Eng 46(11):1264–1267

Shao W, Li XS, Sun Y, Huang H (2017) Parametric study of rock cutting with SMART*CUT picks. Tunn Undergr Space Technol 62:134–144

Thuro K, Plinninger RJ (1999) Predicting roadheader advance rates. Tunn Tunnel 6:36–39

Tiryaki B (2009) Estimating rock cuttability using regression trees and artificial neural networks. Rock Mech Rock Eng 42(6):939–946

Tiryaki B, Dikmen AC (2006) Effects of rock properties on specific cutting energy in linear cutting of sandstones by picks. Rock Mech Rock Eng 39(2):89–120

Tumac D, Bilgin N, Feridunoglu C, Ergin H (2007) Estimation of rock cuttability from shore hardness and compressive strength properties. Rock Mech Rock Eng 40(5):477–490

Wang X, Liang YP, Wang QF, Zhang ZY (2017) Empirical models for tool forces prediction of drag-typed picks based on principal component regression and ridge regression methods. Tunn Undergr Space Technol 62:75–95

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunnel Undergr Space Technol 24:66–74

Yurdakul M, Gopalakrishnan K, Akdas H (2014) Prediction of specific cutting energy in natural stone cutting processes using the neuro-fuzzy methodology. Int J Rock Mech Min Sci 67:127–135

Acknowledgements

The authors gratefully acknowledge the Open Fund of Chongqing Key Laboratory of Manufacturing Equipment Mechanism Design and Control (Grant No. KFJJ2016032), the Chongqing Science and Technology Innovation leading talent support plan (Grant No. CSTCCXLJRC201709), National Science and Technology Major Project of China (Grant No. 2016ZX05043005). The authors also would like to acknowledge to Prof. N. Bilgin, Prof. H. Copur and Prof. C. Balci (Istanbul Technical University, Turkey) for kindly providing data for evaluating the cutting test results.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Wang, QF., Liang, YP. et al. Dominant Cutting Parameters Affecting the Specific Energy of Selected Sandstones when Using Conical Picks and the Development of Empirical Prediction Models. Rock Mech Rock Eng 51, 3111–3128 (2018). https://doi.org/10.1007/s00603-018-1522-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-018-1522-1