Abstract

Practically, all types of rockbursts are accompanied by release of seismic energy, rock bulking (due to fracturing and fragmentation), and ejection of fragmented rocks in the opening. Principles of the energy redistribution during rockbursts in some regards are comparable with principles taking place at spontaneous failure of rock specimens under compression in loading systems. In both cases, the total potential elastic energy accumulated in the failing material and in the loading system (or surrounding rock mass) is converted into such components of dynamic energy as rupture energy, seismic energy (or energy of oscillation of the loading system due to dynamic energy release), and kinetic energy of flying fragments of the failed material. It is known that spontaneous failure takes place at the post-peak failure stage and is determined by the ratio between stiffness of the loading system and stiffness (or brittleness) of the failing material. However, principles of the energy redistribution between different components of the energy balance are still unclear. The paper discusses results of laboratory experiments conducted on rock specimens of different brittleness (including Class I and Class II) that were loaded in testing machines of different loading stiffness. The most brittle of the tested specimens are represented by quartzite and glass, and the less brittle by salt. The loading stiffness of testing machines used in experiments was variable within three decimal orders of magnitude. The specific variations of the dynamic energy balance depending on rock brittleness and loading stiffness were established. The role of each portion of elastic energy stemming from the specimen and from the loading system in determining the dynamic energy balance and fragmentation mechanisms operating at spontaneous failure is analysed. The results obtained contribute to the understanding of dynamic processes taking place during rockbursts.

Similar content being viewed by others

Abbreviations

- E :

-

Elastic modulus

- M :

-

Post-peak modulus

- σ :

-

Axial stress

- ε :

-

Axial strain

- F :

-

Axial force

- d :

-

Axial displacement

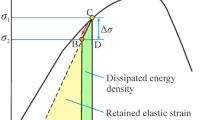

- W e :

-

Elastic energy stored in the specimen at the peak stress

- W r :

-

Total post-peak rupture energy

- W r.in :

-

Internal component of static post-peak rupture energy

- W r.ex :

-

External component of static post-peak rupture energy

- ∆W r(d) :

-

Dynamic increment of the post-peak rupture energy

- W d :

-

Surplus elastic energy responsible for dynamics

- W k :

-

Kinetic energy of rock fragments

- W se :

-

Seismic energy

- dW e :

-

Total elastic energy withdrawn from the specimen during post-peak failure

- dW a :

-

Elastic energy released during spontaneous failure

- m o :

-

Inertial mass of the specimen

- m H :

-

Inertial mass of the loading system

- K 1 :

-

Brittleness index

References

Andreev GE (1995) Brittle failure of rock materials. Balkema, Rotterdam

Aubertin M, Gill DE, Simon R (1994) On the use of the brittleness index modified (BIM) to estimate the post-peak behaviour of rocks. In: Proceedings of the 1st North American rock mechanics symposium, Balkema, pp 945–952

Bergman SGA, Stille H (1983) Rockburst problems in a 2.6 million m3 underground crude oil storage in granite. In: Proceedings of the fifth congress ISRM, pp D302–D309

Bieniawski ZT (1970) Time-dependent behaviour of fractured rock. Rock Mech 2:123–137

Bless SJ, Brar NS, Kanel G, Rosenberg Z (1992) Failure waves in glass. J Am Ceram Soc 75(4):1002–1004

Clucklich J, Cohen LJ (1967) Size as a factor in the brittle–ductile transition and the strength of some materials. Int J Fract Mech 3:278–289

Coates DF (1966) Experimental criteria for classification of rock substances. Int J Rock Min Sci 3:181–189

Cook NGW (1965) The failure of rock. Int J Rock Mech Min Sci 2:389–403

Dight PM, Tarasov BG, O’Hare AW (2013) Determining the proneness of rock to strainburst. In: Malovichko, A, Malovichko, D (eds) 8th international symposium on rockbursts and seismicity in mines. ISBN: 978-5-903258-28-4

Drescher A, Vardoulakis I (1982) Geometric softening in triaxial tests on granular material. Geotechnique 32:291–3003

Galin LA, Cherepanov GI (1966) On self-supporting failure of a stressed brittle solid. Dokl AN SSSR 167(3):543–546 (in Russian)

Grady DE (1981) Fragmentation of solids under impulsive stress loading. J Geophys Res 86(B2):1047–1054

He C, Okubo A, Nishimatsu Y (1990) A study on the class II behaviour of rock. Rock Mech Rock Eng 32:261–273

Horii H, Nemat-Nasser S (1985) Compression-induced micro-crack growth in brittle solids: axial splitting and shear failure. J Geophys Res 90:3105–3125

Hucka V, Das B (1974) Brittleness determination of rocks by different methods. Int J Rock Mech Min Sci 11:389–392

Hudson JA, Crouch SL, Fairhurst C (1972) Soft, stiff and servo-controlled testing machines: a review with reference to rock failure. Eng Geol 6:155–189

Inoue A, Shen BL, Chang CT (2004) Super-high strength of over 4000 MPa for Fe-based bulk glassy alloys. Acta Mater 52:4093–4099

Jacobsson L (2007) Forsmark site investigation—Borehole KFM01C—UCS. SP Swedish National Testing and Research Institute, Boras

Kaiser PK, Cai M (2013) Critical review of design principles for rock support in burst-prone ground-time to rethink!. In: Potvin Y, Brady B (eds) Proceedings of the seventh international symposium on ground support in mining and underground construction, Australian Centre for Geomechanics, Perth, pp 3–37

Kanel GI, Razorenov SV, Fortov VE (2005) A failure wave phenomenon in brittle materials. In: Joint 20th AIRAPT–43th EHPRG, Karlsruhe/Germany

Kidybinski A (1981) Bursting liability indices of coal. Int J Rock Mech Min Sci 18:295–304

King GCP, Sammis CG (1992) The mechanisms of finite brittle strain. PAGEOPH 138(4):611–640

Labuz JF, Biolzi L (1991) Class I vs Class II stability: a demonstration of size effect. Int J Rock Mech Min Sci Geomech Abstr 28(2/3):199–205

Lockner DA, Byerlee JD, Kuksenko V, Ponomarev A, Sidorin A (1992) Observations of quasi-static fault growth from acoustic emissions. In: Evans B, Wong T-F (eds) Fault mechanics and transport properties of rocks. Academic, San Diego, pp 3–31

McGarr A (1997) A mechanism for high wall-rock velocities in rockbursts. Pure appl Geophys 150:381–391

Okubo S, Nishimatsu Y, He C (1990) Loading rate dependence of Class II rock behaviour in uniaxial and triaxial compression tests—an application of a proposed new control method. Int J Rock Mech Min Sci Geomech Abstr 27(6):559–562

Ortlepp WD, Stacey TR (1994) Rockburst mechanisms in tunnels and shafts. Tunn Undergr Space Technol 9(1):59–65

Peng S, Johnson AM (1972) Crack growth and faulting in cylindrical specimens of Chelmsford granite. Int J Rock Mech Min Sci 9:37–86

Petoukhov IM, Linkov AM (1983) Mechanics of rockburst and outburst. Nedra, Moscow

Raith MM, Raase P, Reinhardt J (2012) Guide to thin section microscopy, 2nd edn. ISBN: 978-3-00-037671-9

Read HE, Hegemier GA (1984) Strain softening of rock, soil and concrete—a review article. Mech Mater 3:271–294

Reches Z, Lockner DA (1994) Nucleation and growth of faults in brittle rocks. J Geophys Res 99(B9):18159–18173

Rinehart JS (1965) Dynamic fracture strengths of rocks. In: Proceedings of the seventh symposium on rock mechanics. Pennsylvania State University

Rosakis AJ (2002) Intersonic shear cracks and fault ruptures. Adv Phys 51(4):1189–1257

Stavrogin AN (1968) Strength and deformation of rocks. Highest doctoral degree of technical science. The USSR State Geomechanical Institute, Leningrad

Stavrogin AN, Protossenia AG (1985) Rock strength and excavation stability in great depth. Nedra, Moscow

Stavrogin AN, Tarasov BG (2001) Experimental physics and rock mechanics. Balkema, Rotterdam

Stipp M, Stunitz H, Heilbronner R, Schmid SM (2002) The eastern Tonale fault zone: a ‘natural laboratory’ for crystal plastic deformation of quartz over a temperature range from 250 to 700°C. J Struct Geol 24:1861–1884

Tarasov BG (2010) Superbrittleness of rocks at high confining pressure. Keynote lecture In: Van Sint Jan M, Potvin Y (eds) Fifth international seminar on deep and high stress mining, Santiago, Chile, pp 119–133

Tarasov BG (2014) Hitherto unknown shear rupture mechanism as a source of instability in intact hard rocks at highly confined compression. Tectonophysics 621:69–84

Tarasov BG, Potvin Y (2013) Universal criteria for rock brittleness estimation under triaxial compression. Int J Rock Mech Min Sci 59:57–69

Wawersik WR, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci 7:561–575

Wu FF, Zhang ZZ, Shen BL, Mao SXY, Eckert J (2008) Size effect on shear fracture and fragmentation of a bulk metallic glass. Adv Eng Mater 10(8):727–730

Xu YH, Cai M (2017) Influence of loading system stiffness on post-peak stress-strain curve of stable rock failures. Rock Mech Rock Eng. doi:10.1007/s00603-017-1231-1

Yang B, Liaw PK, Wang G, Morrison M, Liu CT, Buchanan RA, Yokoyama Y (2004) In-situ thermographic observation of mechanical damage in bulk-metallic glasses during fatigue and tensile experiments. Intermetallics 12:1265–1274

Zhang ZF, Zhang H, Shen BL, Inoue A, Eckert J (2006) Shear fracture and fragmentation mechanisms of bulk metallic glasses. Philos Mag Lett 86(10):643–650

Acknowledgements

The authors acknowledge the support provided by the Centre for Offshore Foundation Systems (COFS) at the University of Western Australia.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

See Fig. 22.

Stress–strain curves obtained at different strain rates for 1 marble, 2 granite, 3 sandstone-1, 4 sandstone-2, 5 sulphide ore, 6 lignite, 7 rock salt, 8 sylvinite. During each test constant, strain rate was provided before and after peak stress. The magnitude of strain rate \(\acute{\varepsilon}_1\) for each stress–strain curve is presented in the table (from Stavrogin and Tarasov 2001)

Rights and permissions

About this article

Cite this article

Tarasov, B.G., Stacey, T.R. Features of the Energy Balance and Fragmentation Mechanisms at Spontaneous Failure of Class I and Class II Rocks. Rock Mech Rock Eng 50, 2563–2584 (2017). https://doi.org/10.1007/s00603-017-1251-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1251-x