Abstract

This study aims at determining the effects of single-, double-, and triple-spiral cutting patterns; the effects of tool cutting speeds on the experimental scale; and the effects of the method of yield estimation on cutting performance by performing a set of full-scale linear cutting tests with a conical cutting tool. The average and maximum normal, cutting and side forces; specific energy; yield; and coarseness index are measured and compared in each cutting pattern at a 25-mm line spacing, at varying depths of cut per revolution, and using two cutting speeds on five different rock samples. The results indicate that the optimum specific energy decreases by approximately 25% with an increasing number of spirals from the single- to the double-spiral cutting pattern for the hard rocks, whereas generally little effect was observed for the soft- and medium-strength rocks. The double-spiral cutting pattern appeared to be more effective than the single- or triple-spiral cutting pattern and had an advantage of lower side forces. The tool cutting speed had no apparent effect on the cutting performance. The estimation of the specific energy by the yield based on the theoretical swept area was not significantly different from that estimated by the yield based on the muck weighing, especially for the double- and triple-spiral cutting patterns and with the optimum ratio of line spacing to depth of cut per revolution. This study also demonstrated that the cutterhead and mechanical miner designs, semi-theoretical deterministic computer simulations and empirical performance predictions and optimization models should be based on realistic experimental simulations. Studies should be continued to obtain more reliable results by creating a larger database of laboratory tests and field performance records for mechanical miners using drag tools.

Similar content being viewed by others

References

Avunduk E, Tumac D, Copur H, Balci C, Bilgin N (2013) Experimental comparison of single and double scroll cutting patterns by using chisel cutting tools of chain saw machines. In: Feng XT, Hudson JA, Tan F (eds) Proceedings of the Sinorock 2013, pp 729–734

Balci C, Bilgin N (2007) Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines. Int J Rock Mech Min Sci 44:468–476

Balci C, Demircin MA, Copur H, Tuncdemir H (2004) Estimation of optimum specific energy based rock properties for assessment of roadheader performance. J S Afr I Min Metall 104(11):633–642

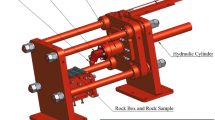

Balci C, Comakli R, Polat C, Tumac D, Avunduk E, Copur H, Bilgin N (2015) A new generation of portable linear rock cutting machine (PLCM) and comparison with full scale linear rock cutting tests. In: Proceedings of the world tunnel congress, Dubrovnik, Croatia

Balci C, Bilgin N, Copur H, Tumac D (2016) Investigation of some rock cuttability parameters to select mechanical excavators by a developed mini portable linear rock cutting machine. Report (112M859) submitted to Tubitak

Barker JS (1964) A laboratory investigation of rock cutting using large picks. Int J Rock Mech Min Sci 1:468–476

Barker JS, Pomeroy CD, Whittaker D (1966) The M.R.E. Large-pick shearer drum. The Mining Engineer, February, pp 323–331

Bilgin N, Balci C et al (1999) The performance prediction of a TBM in Tuzla-Dragos Sewerage Tunnel. In: Proceedings of the world tunnel congress, Oslo, 31 May–3 June, pp 817–822

Bilgin N, Tuncdemir H, Balci C, Copur H, Eskikaya S (2000) A model to predict the performance of tunneling machines under stressed conditions. In: Proceedings of the world tunnel congress, Johannesburg, May 13–18, pp 47–53

Bilgin N, Demircin MA, Copur H, Balci C, Tuncdemir H, Akcin N (2006) Dominant rock properties affecting the performance of conical cutters and the comparison of some experimental and theoretical results. Int J Rock Mech Min Sci 43:139–156

Bilgin N, Copur H, Balci C (2014) Mechanical excavation in mining and civil industries. CRC Press, Taylor & Francis Group, Boca Raton. ISBN 978-1466584747

Brooker CM (1979) Theoretical and practical aspects of cutting and loading by shearer drums. Part-I. Colliery Guardian Coal International, January: 9–16

Cook NGW, Jougin NC, Weibols GA (1968) Rock cutting and its potentialities as new method of mining. J S Afr I Min Metall, May: 435–454

Copur H (1999) Theoretical and experimental studies of rock cutting with drag bits toward the development of a performance prediction model for roadheaders. Dissertation, Colorado School of Mines, 361 p

Copur H (2010) Linear stone cutting tests with chisel tools for identification of cutting principles and predicting performance of chain saw machines. Int J Rock Mech Min Sci 47(1):104–120

Copur H, Tuncdemir H, Bilgin N, Dincer T (2001) Specific energy as a criterion for the use of rapid excavation systems in Turkish Mines. IMM Trans A Mining Tech 110(A):149-157

Copur H, Bilgin N, Tuncdemir H, Balci C (2003) A set of indices based on indentation tests for assessment of rock cutting performance and rock properties. J S Afr I Min Metall 103(9):589–600

Copur H, Balci C, Tumac D, Bilgin N (2011) Field and laboratory studies on natural stones leading to empirical performance prediction of chain saw machines. Int J Rock Mech Min Sci 48(2):269–282

Copur H, Bilgin N, Balci C, Tumac D, Avunduk E, Mamaghani AS (2016) Full-scale linear cutting experiments with a conical cutter for simulating different cutting patterns. In: Ulusay R et al (eds) Proceedings of the 2016 ISRM international symposium “EUROCK 2016”, 29–31 August, Cappadocia, Turkey, vol 1, pp 153–158

Demou SG, Olson RC, Wingquist CF (1983) Determination of bit forces encountered in hard rock cutting for application to continuous miner design. US Bureau of Mines, RI-8748

Evans I (1984) A theory of the cutting force for point attack picks. Int J Min Eng 2:63–71

Evans I, Pomeroy CD (1966) The strength, fracture and workability of coal. Pergamon Press, Oxford

Fowell RJ, McFeat Smith I (1976) Factors influencing the cutting performance of a selective tunnelling machine. In: Proceedings of the international symposium IMM (Tunelling’76), London, pp 301–318

Hignet HJ, O’Reilly MP (1977) The arrangement of rock cutting tools on full face tunnel boring machines. In: Proceedings of the conference on rock engineering, 4–7 April, Newcastle Upon Tyne, pp 557–580

Hurt KG (1980) Rock cutting experiments with point attack tools. Colliery Guardian Coal International, April, pp 47–50

Hurt KG, Evans I (1980) A laboratory study of rock cutting using point attack tools. In: Summers D (ed) Proceedings of the 21st symposium on rock mechanics, pp 112–122

Hurt KG, Laidlaw DD (1979) Laboratory comparison of three rock cutting tools. Tunn Tunnel, May: 13–16

Hurt KG, MacAndrew KM (1981) Designing roadheader cutting heads. Min Eng, September: 167–170

Hurt KG, Morris CJ (1985) Computer designed cutting heads improve roadheader performance. Tunn Tunn, March: 37–38

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Suggested methods prepared by the ISRM commission on testing methods, compilation arranged by the ISRM Turkish National Group. Kozan Ofset, Ankara, p 628

Kim E, Rostami J, Swope C, Colvin S (2012) Study of conical bit rotation using full-scale rotary cutting experiments. J Min Sci 48(4):717–731

McFeat Smith I, Fowell RJ (1977) Correlation of rock properties and the cutting performance of tunnelling machines. In: Proceedings of the conference on rock engineering, University of Newcastle Upon Tyne, pp 581–602

McFeat-Smith I, Fowell RJ (1979) The selection and application of roadheaders for rock tunnelling. In: Proceedings of the rapid excavation and tunnelling conference, Atlanta, pp 261–280

Mellor M (1975) Mechanics of cutting and boring, Part 1: kinematics of transverse rotation machines. CRREL (US Army, Cold Regions Research and Engineering Laboratory, Hanover, New Hampshire), Special Report, No: 226

Mishnaevsky LL (1995) Physical mechanisms of hard rock fragmentation under mechanical loading: a review. Int J Rock Mech Min Sci 32:763–766

Nishimatsu Y (1979) On the effect of tool velocity in rock cutting. In: International conference on mining machinery, Brisbane, Australia, 2–6 July, pp 314–319

O’Dogherty MJ, Burney AC (1963) A laboratory study of the effect of cutting speed on the performance of two coal cutter picks, Part II. Colliery Eng, March: 111–114

Pomeroy CD (1958) The effect of lateral pressure on the cutting of coal by wedge shaped tools. In: Walton WH (ed) Proceedings of the congress on mechanical properties of non-metallic brittle materials. Butter Worths Scientific Publications, London, pp 469–479

Pomeroy CD (1963) Breakage of coal by wedge action: factors affecting breakage by any given shape of tool. Colliery Guardian, November 21: 642–648; November 28: 672–677

Pomeroy CD, Foote P (1960) A laboratory investigation of the relation between ploughability and the mechanical properties of coal. Colliery Eng, April: 146–154

Potts ELJ, Shuttleworth P (1958) A study on the ploughability of coal, with special reference to the effects of blade shape, direction of planing to the cleat, planing speed and the influence of water infusion. Trans Inst Min Eng 117:519–553

Roepke WW, Voltz JI (1983) Coal cutting forces and primary dust generation using radial gage cutters. US Bureau of Mines, RI-8800

Rostami J (2011) Mechanical rock breaking. In:Darling P (ed) SME mining engineering handbook, 3rd edn. Chapt 7.1, Society for Mining, Metallurgy and Exploration Inc., pp 417–434

Rostami J, Ozdemir L, Neil DM (1994a) Performance prediction: a key issue in mechanical hard rock mining. Min Eng 11:1263–1267

Rostami J, Ozdemir L, Neil DM (1994b) Roadheaders performance optimization for mining and civil construction. In: Proceedings of the 13th annual technical conference, Institute of Shaft Drilling Technology, Las Vegas, Nevada, April 18–21

Rostami J, Monroe S, Ozdemir L (1997) Recent advances in continuous miner design and performance optimization for increased productivity. In: Gurgenci H, Hood M (eds) Proceedings of the 4th international symposium on mine mechanization and automation, Brisbane, Queensland, Australia, July 6–9, vol 2, pp. A5-15–A5-24

Roxborough FF (1973) Cutting rock with picks. Min Eng, June: 445–452

Roxborough FF (1988) Multiple pass sub-interactive rock cutting with picks and discs. In: CARE’88 (conference on applied rock engineering), University of Newcastle upon Tyne, IMM, pp 183–191

Roxborough FF, Phillips HR (1974) Experimental studies on the excavation of rock using picks. In: Proceedings of the 3rd International ISRM Congress, Denver, vol 1, Part B, pp 1407–1412

Roxborough FF, Phillips HR (1981) Applied rock and coal cutting mechanics. Workshop Course, Australian Mineral Foundation, Adelaide, 11–15 May

Roxborough FF, Rispin A (1973) The mechanical cutting characteristics of the lower chalk. Tunnels and Tunnelling 5:45–67

Standerline GV, Evans I (1960) Power loading in South Wales and its effect on the degradation of coal. Colliery Guardian, November: 119–139

Tumac D, Avunduk E, Basyigit M, Copur H, Balci C, Er S (2015) The effect of mechanical properties on performance of diamond wire machines. In: Fuenkajorn K, Phien-wej N (eds) Proceedings of the 5th Thailand symposium on rock mechanics, Nakhon Ratchasima, Thailand, 22–23 Jan, pp 389–395

Tuncdemir H, Bilgin N, Copur H, Balci C (2008) Control of rock cutting efficiency by muck size. Int J Rock Mech Min Sci 45(2):278–288

Werblow W (1961) Coal ploughing, an examination of blade angle. Colliery Eng, August: 345–350

West G (1989) Rock abrasiveness testing for tunnelling. Int J Rock Mech Min Sci 26(2):151–160

Whittaker D (1962) Effect of pick shape on cutting forces. Colliery Guardian, August 23: 242–244

Acknowledgements

This study is a result of a long-term research activity performed by the Mechanical Excavation Research Group in the Mining Engineering Department of Istanbul Technical University. The members of this group, who are the authors of this article, would like to take this opportunity to convey their appreciation to Prof. Dr. Nuh Bilgin, who has provided inspiration and encouragement to them along with enthusiasm for developing research on rock and soil-cutting science at the Istanbul Technical University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Copur, H., Bilgin, N., Balci, C. et al. Effects of Different Cutting Patterns and Experimental Conditions on the Performance of a Conical Drag Tool. Rock Mech Rock Eng 50, 1585–1609 (2017). https://doi.org/10.1007/s00603-017-1172-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1172-8