Abstract

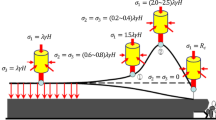

Physical model testing is an important research tool for coal petrography engineering as it can solve many difficult problems associated with high risks and requiring long time periods to investigate with field studies. However, the accuracy of physical model tests can be reduced by problems with testing equipment, such as small model specimen size, poor airtightness and insufficient stress and pressure loading ability. To study the problems of coal petrography engineering in complicated stress environments, especially those in fluid–solid coupling, we designed and developed a multi-functional physical model testing system. The entire testing system consists of several specific sub-systems: loading, specimen shaping and installation, data monitoring and acquisition, pumping and gas injection, excavation simulating. The testing system can simulate complicated stress environments of coal-rock mass, and it can also be used to study the characteristics of strength-deformation, seepage-rheology and instability-failure under the conditions of gas–solid coupling and gas–liquid–solid multi-phase coupling. A load–unload experiment of air pressure and three-dimensional stress was conducted using the testing system. The experiment verified major technical indicators such as the loading capacity, sealing pressure and test precision, as well as operational stability of the testing system. The strain fields within the model specimen are well distributed and approximately linear with the stress. The stress of the specimen surface is approximately well distributed, and the specimen is subjected to uniform stresses. The testing system meets the requirements of the design parameters and has great potential significance to help reveal the scientific laws and inherent mechanisms of coal petrography engineering.

Similar content being viewed by others

References

Alexeev AD, Revva VN, Alyshev NA et al (2004) True triaxial loading apparatus and its application to coal outburst prediction. Int J Coal Geol 58(4):245–250

Chang C, Haimson B (2005) Non-dilatant deformation and failure mechanism in two Long Valley Caldera rocks under true triaxial compression. Int J Rock Mech Min Sci 42(3):402–414

De A, Morgante AN, Zimmie TF et al (2016) Numerical and physical modeling of geofoam barriers as protection against effects of surface blast on underground tunnels. Geotext Geomembr 44(1):1–12

Drosos VA, Anastasopoulos I (2015) Experimental investigation of the seismic response of classical temple columns. Bull Earthq Eng 13(1):299–310

Frash LP, Gutierrez M, Hampton J (2014) True-triaxial apparatus for simulation of hydraulically fractured multi-borehole hot dry rock reservoirs. Int J Rock Mech Min 70:496–506

He MC, Zhao F, Cai M et al (2015) A novel experimental technique to simulate pillar bursting laboratory. Rock Mech Rock Eng 48(5):1833–1848

Hoyos LR, Pérez-Ruiz DD, Puppala AJ (2012) Modeling unsaturated soil response under suction-controlled true triaxial stress paths. Int J Geomech 12(3):292–308

Huang BX, Li PF, Ma J et al (2014) Experimental investigation on the basic law of hydraulic fracturing after water pressure control blasting. Rock Mech Rock Eng 47(4):1321–1334

Jiang YD, Liu WG, Zhao YX (2004) Design and development of a new type of triaxial system for roadway model test. Chin J Rock Mech Eng 23(21):3727–3731 (in Chinese)

Li SC, Wang Q, Wang HT et al (2015) Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn Undergr Space Technol 47:52–63

Liang DX, Jiang ZQ, Zhu SY et al (2016) Experimental research on water inrush in tunnel construction. Nat Hazards 81(1):467–480

Liu AH, Peng SQ, Li XB (2009) Development and application of similar physical model experiment system for water inrush mechanism in deep mining. Chin J Rock Mech Eng 28(7):1335–1341 (in Chinese)

Nasseri MHB, Goodfellow SD, Lombos L et al (2014) 3-D transport and acoustic properties of Fontainebleau sandstone during true-triaxial deformation experiments. Int J Rock Mech Min Sci 69:1–18

Rafiee R, Ataei M, Khalokakaie R et al (2015) Determination and assessment of parameters influencing rock mass cavability in block caving mines using the probabilistic rock engineering system. Rock Mech Rock Eng 48(3):1207–1220

Seki S, Kaise S, Morisaki Y et al (2008) Model experiments for examining heaving phenomenon in tunnels. Tunn Undergr Space Technol 23(2):128–138

Sellers EJ, Klerck P (2000) Modeling of the effect of discontinuities on the extent of the fracture zone surrounding deep tunnels. Tunn Undergr Space Technol 15(4):463–469

Skoczylas N (2012) Laboratory study of the phenomenon of methane and coal outburst. Int J Rock Mech Min 55:102–107

Sobczyk J (2011) The influence of sorption processes on gas stresses leading to the coal and gas outburst in the laboratory conditions. Fuel 90(3):1018–1023

Sun J, Wang SJ (2000) Rock mechanics and rock engineering in China: developments and current state-of-the-art. Int J Rock Mech Min Sci 37(3):447–465

Tu QY, Cheng YP, Guo PK et al (2016) Experimental study of coal and gas outbursts related to gas-enriched areas. Rock Mech Rock Eng 49(9):3769–3781

Ujihira M, Isobe T, Higuchi K (1984) On the proeess of destruction of porous material in which high pressure gas is involved. J Min Metall Inst Jpn 100(5):397–403 (in Japanese)

Zhao YS, Wan ZJ, Zhang Y (2009) Research and development of 20 MN servo-controlled rock triaxial testing system with high temperature and high pressure. Chin J Rock Mech Eng 28(7):1335–1341 (in Chinese)

Acknowledgements

The work is jointly supported by the National Key Basic Research Program of China (No. 2014CB239206), the National Natural Science Foundation of China (No. 51374258), the Chongqing Graduate Student Research Innovation Project 2015 (No. CYB15009) and the Program for Changjiang Scholars and Innovative Research Team in University of China (No. IRT13043).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Wang, H., Xia, B. et al. Development of a Multi-functional Physical Model Testing System for Deep Coal Petrography Engineering. Rock Mech Rock Eng 50, 269–283 (2017). https://doi.org/10.1007/s00603-016-1124-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-1124-8