Abstract

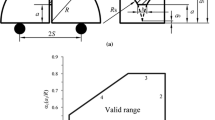

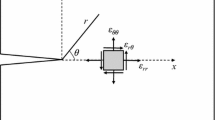

The cracked chevron notched Brazilian disc (CCNBD) specimen has been suggested by the International Society for Rock Mechanics to measure the mode I fracture toughness of rocks, and has been widely adopted in laboratory tests. Nevertheless, a certain discrepancy has been observed in results when compared with those derived from methods using straight through cracked specimens, which might be due to the fact that the fracture profiles of rock specimens cannot match the straight through crack front as assumed in the measuring principle. In this study, the progressive fracturing of the CCNBD specimen is numerically investigated using the discrete element method (DEM), aiming to evaluate the impact of the realistic cracking profiles on the mode I fracture toughness measurements. The obtained results validate the curved fracture fronts throughout the fracture process, as reported in the literature. The fracture toughness is subsequently determined via the proposed G-method originated from Griffith’s energy theory, in which the evolution of the realistic fracture profile as well as the accumulated fracture energy is quantified by DEM simulation. A comparison between the numerical tests and the experimental results derived from both the CCNBD and the semi-circular bend (SCB) specimens verifies that the G-method incorporating realistic fracture profiles can contribute to narrowing down the gap between the fracture toughness values measured via the CCNBD and the SCB method.

Similar content being viewed by others

References

Abe S, Place D, Mora P (2004) A parallel implementation of the lattice solid model for the simulation of rock mechanics and earthquake dynamics. Pure Appl Geophys 161(11–12):2265–2277

Amenta N, Bern M, Kamvysselis M (1998) A new Voronoi-based surface reconstruction algorithm. In: Proceedings of the 25th annual conference on computer graphics and interactive techniques, SIGGRAPH’98, pp 415–421

Chang S-H, Lee C-I, Jeon S (2002) Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens. Eng Geol 66:79–97

Chen JF (1990) The development of the cracked-chevron-notched Brazilian disc method for rock fracture toughness measurement. In: Proceeding of 1990 SEM Spring Conference on Experimental Mechanics, Albuquerque, U.S.A., pp 18–23

Cui ZD, Liu DA, An GM, Sun B, Zhou M, Cao FQ (2010) A comparison of two ISRM suggested chevron notched specimens for testing mode I rock fracture toughness. Int J Rock Mech Min Sci 47:871–876

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

Dai F, Chen R, Iqbal MJ, Xia K (2010) Dynamic cracked chevron notched Brazilian disc method for measuring rock fracture parameters. Int J Rock Mech Min Sci 47:606–613

Dai F, Wei MD, Xu NW, Ma Y, Yang DS (2015a) Numerical assessment of the progressive rock fracture mechanism of cracked chevron notched Brazilian disc specimens. Rock Mech Rock Eng 48(2):463–479

Dai F, Wei MD, Xu NW, Zhao T, Xu Y (2015b) Numerical investigation of the progressive fracture mechanisms of four ISRM-suggested specimens for determining the mode I fracture toughness of rocks. Comput Geotech 69:424–441

Dwivedi RD, Soni AK, Goel RK, Dube AK (2000) Fracture toughness of rocks under sub-zero temperature conditions. Int J Rock Mech Min Sci 37:1267–1275

Edelsbrunner H, Mȕcke EP (1994) Three-dimensional alpha shapes. ACM Trans Graph 13:43–72

Fowell RJ (1995) ISRM commission on testing methods. Suggested method for determining mode I fracture toughness using cracked chevron notched Brazilian disc (CCNBD) specimens. Int J Rock Mech Min Sci Geomech Abstr 32(1):57–64

Griffith AA (1920) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond A221:163–198

Hazzard JF, Young RP (2000) Simulating acoustic emissions in bonded particle models of rock. Int J Rock Mech Min Sci Geomech Abstr 37:867–872

Hazzard JF, Young RP, Maxwell SC (2000) Micromechanical modeling of cracking and failure in brittle rocks. J Geophys Res 105(B7):16683–16697

Iqbal MJ, Mohanty B (2007) Experimental calibration of ISRM suggested fracture toughness measurement techniques in selected brittle rocks. Rock Mech Rock Eng 40(5):453–475

Irwin GR (1957) Analysis of stresses and strains near the end of a crack traversing a plate. J Appl Mech 24:361–364

Khazaei C, Hazzard J, Chalaturnyk R (2015) Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput Geotech 67:94–102

Kourkoulis SK, Markides ChF (2014) Fracture toughness determined by the centrally cracked Brazilian disc test: Some critical issues in the light of an alternative analytic solution. ASTM Mater Perform Charact 3(3):45–86

Kuruppu MD, Obara Y, Ayatollahi MR, Chong KP, Funatsu T (2014) ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech Rock Eng 47(1):267–274

Markides ChF, Kourkoulis SK (2016) ‘Mathematical’ cracks versus artificial slits: implications in the determination of fracture toughness. Rock Mech Rock Eng 49(3):707–729

Nasseri MHB, Mohanty B, Young RP (2006) Fracture toughness measurements and acoustic emission activity in brittle rocks. Pure appl Geophys 163:917–945

Ouchterlony F (1988) ISRM commission on testing methods. Suggested methods for determining fracture toughness of rock. Int J Rock Mech Min Sci Geomech Abstr 25:71–96

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min 41:1329–1364

Singh RN, Sun G (1990) Application of fracture mechanics to some mining engineering problems. Min Sci Technol 10:53–60

Tutluoglu L, Keles C (2011) Mode I fracture toughness determination with straight notched disk bending method. Int J Rock Mech Min Sci 48:1248–1261

Utili S, Zhao T, Houlsby GT (2014) 3D DEM investigation of granular column collapse: evaluation of debris motion and its destructive power. Eng Geol 186:3–16

Wang QZ, Jia XM, Kou SQ, Zhang ZX, Lindqvist P-A (2003) More accurate stress intensity factor derived by finite element analysis for the ISRM suggested rock fracture toughness specimen-CCNBD. Int J Rock Mech Min Sci 40(2):233–241

Wang QZ, Fan H, Gou XP, Zhang S (2013) Recalibration and clarification of the formula applied to the ISRM-suggested CCNBD specimens for testing rock fracture toughness. Rock Mech Rock Eng 46(2):303–313

Wei M, Dai F, Xu N, Xu Y, Xia K (2015a) Three-dimensional numerical evaluation of the progressive fracture mechanism of cracked chevron notched semi-circular bend rock specimens. Eng Fract Mech 134:286–303

Wei M, Dai F, Xu NW, Liu JF, Xu Y (2015b) Experimental and numerical study on the cracked chevron notched semi-circular bend method for characterizing the mode I fracture toughness of rocks. Rock Mech Rock Eng. doi:10.1007/s00603-015-0855-2

Xu C, Fowell RJ (1994) Stress intensity factor evaluation for cracked chevron notched Brazilian disc specimen. Int J Rock Mech Min Sci Geomech Abstr 31:157–162

Xu NW, Dai F, Wei MD, Xu Y, Zhao T (2016) Numerical observation of three dimensional wing-cracking of cracked chevron notched Brazilian disc rock specimen subjected to mixed mode loading. Rock Mech Rock Eng 49:79–96

Yoon JS, Zang A, Stephansson O (2012) Simulating fracture and friction of Aue granite under confined asymmetric compressive test using clumped particle model. Int J Rock Mech Min Sci 49:68–83

Zhao T, Dai F, Xu NW, Liu Y, Xu Y (2015) A composite particle model for non-spherical particles in DEM simulations. Granul Matter 17(6):763–774

Acknowledgments

The authors are grateful for the financial support from the National Program on Key basic Research Project (No. 2015CB057903), National Natural Science Foundation of China (No. 51374149), Program for New Century Excellent Talents in University (NCET-13-0382) and the Youth Science and Technology Fund of Sichuan Province (2014JQ0004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Y., Dai, F., Zhao, T. et al. Fracture Toughness Determination of Cracked Chevron Notched Brazilian Disc Rock Specimen via Griffith Energy Criterion Incorporating Realistic Fracture Profiles. Rock Mech Rock Eng 49, 3083–3093 (2016). https://doi.org/10.1007/s00603-016-0978-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-0978-0