Abstract

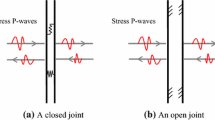

As a key dynamic feature of the rock mass, joint results in wave attenuation when a stress wave propagates across it. An experimental study has obtained the relation between the transmission coefficient and the contact area ratio of joints with different thicknesses (Chen et al. (doi:10.1007/s00603-015-0716-z)). However, the spatial geometry of the contact surface also determines the dynamic behavior of the discontinuous masses. Thus, the present study is focused on the effects of distribution and dimension of the sawn notches on the contact surface of the joint, which lead to the different spatial geometry. The joint matching coefficient (JMC) was used in this study to define the contact condition. Using a modified SHPB apparatus, all the bars and specimens were aluminum, and the artificial joint formed a rough surface of the specimen contacted to the output bar. Based on the wave separation method, the incident, reflected and transmitted waves across the joint were acquired from the records of the strain gauges on pressure bars. Then the transmission coefficient and specific stiffness of the joint were obtained. Comparisons of them were made on different JMCs, spatial geometries and thicknesses of the joint.

Similar content being viewed by others

Abbreviations

- \(\varepsilon_{\text{A}} (t)\), \(\varepsilon_{\text{B}} (t)\) :

-

Test records of the strain gauges A and B

- \(\varepsilon (t)\) :

-

Strain at time t

- \(\varepsilon^{p} (t)\), \(\varepsilon^{n} (t)\) :

-

Positive and negative strains

- \(\varepsilon_{A}^{p} (t)\), \(\varepsilon_{A}^{n} (t)\), \(\varepsilon_{B}^{p} (t)\), \(\varepsilon_{B}^{n} (t)\) :

-

Positive and negative strains at the positions of the strain gauges A and B

- x A , x B :

-

Distance between the end surface O and the strain gauge A and B respectively

- \(\Delta t\) :

-

Time interval for positive or negative strain wave propagation between the positions of the strain gauges A and B

- \(\sigma\) :

-

Stress of the joint

- E :

-

Young’s modulus of the aluminum bar

- \(\varepsilon_{I}\), \(\varepsilon_{T}\) :

-

Strains of the input and output bars

- \(\varepsilon_{I}^{p}\), \(\varepsilon_{I}^{n}\), \(\varepsilon_{T}^{p}\), \(\varepsilon_{T}^{n}\) :

-

Positive and negative strains of the input and output bars respectively

- v(t):

-

Particle velocity

- c :

-

P wave propagation velocity in the aluminum bar

- \(\dot{\varepsilon }\) :

-

Strain rate of the joint

- L :

-

Joint thickness

- \(\Delta L\) :

-

Normal closure of the joint

- T :

-

Transmission coefficient of the joint

- α, β, γ, φ:

-

Coefficients of the fitting curves

References

Chen X, Li JC, Cai MF, Zou Y, Zhao J (2015) Experimental study on wave propagation across a rock joint with rough surface. Rock Mech Rock Eng. doi:10.1007/s00603-015-0716-z

Field JE, Walley SM, Proud WG et al (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30(7):725–775. doi:10.1016/j.ijimpeng.2004.03.005

Huang SL, Oelfke SM, Speck RC (1992) Applicability of fractal characterization and modelling to rock joint profiles. Int J Rock Mech Min Sci Geomech Abstr 29(92):89–98. doi:10.1016/0148-9062(92)92120-2

Jiang YJ, Li B, Tanabashia Y (2006) Estimating the relation between surface roughness and mechanical properties of rock joints. Int J Rock Mech Min Sci 43(2006):837–846. doi:10.1016/j.ijrmms.2005.11.013

Ju Y, Sudak L, Xie HP (2007) Study on stress wave propagation in fractured rocks with fractal joint surfaces. Int J Solids Struct 44:4256–4271. doi:10.1016/j.ijsolstr.2006.11.015

Kahraman S (2002) The effects of fracture roughness on P-wave velocity. Eng Geol 63:347–350. doi:10.1016/S0013-7952(01)00089-8

Lee YH, Carr JR, Barr DJ et al (1990) The fractal dimension as a measure of the roughness of rock discontinuity profiles. Int J Rock Mech Min Sci Geomech Abstr 27(90):453–464. doi:10.1016/0148-9062(90)90998-H

Li JC, Ma GW (2009) Experimental study of stress wave propagation across a filled rock joint. Int J Rock Mech Min Sci 46(3):471–478. doi:10.1016/j.ijrmms.2008.11.006

Li XB, Lok TS, Zhao J (2000) Oscillation elimination in the Hopkinson bar apparatus and resultant complete dynamic stress–strain curves for rocks. Int J Rock Mech Min Sci 37(7):1055–1060. doi:10.1016/S1365-1609(00)00037-X

Miller RK (1977) An approximate method of analysis of the transmission of elastic waves through a frictional boundary. J Appl Mech 44(4):652. doi:10.1115/1.3424152

Pyrak-Nolte LJ (1996) The seismic response of fractures and the interrelations among fracture properties. Int J Rock Mech Min Sci Geomech Abstr 33(8):787–802. doi:10.1016/S0148-9062(96)00022-8

Pyrak-Nolte LJ, Morris JP (2000) Single fractures under normal stress: the relation between fracture specific stiffness and fluid flow. Int J Rock Mech Min Sci 37(18):245–262. doi:10.1016/S1365-1609(99)00104-5

Pyrak-Nolte LJ, Myer LR, Cook NGW (1990) Transmission of seismic waves across single natural fractures. J Geophys Res 95(6):8617–8638. doi:10.1029/JB095iB06p08617

Wu W, Li JC, Zhao J (2014) Role of filling materials in a P-wave interaction with a rock fracture. Eng Geo 172:77–84. doi:10.1016/j.enggeo.2014.01.007

Xia K, Nasseri MHB, Mohanty B et al (2008) Effects of microstructures on dynamic compression of Barre granite. Int J Rock Mech Min Sci 45(6):879–887. doi:10.1016/j.ijrmms.2007.09.013

Zhao J (1997a) Joint surface matching and shear strength—part a: joint matching coefficient (JMC). Int J Rock Mech Min Sci 34(2):173–178. doi:10.1016/S0148-9062(96)00062-9

Zhao J (1997b) Joint surface matching and shear strength—part b: JRC-JMC shear strength criterion. Int J Rock Mech Min Sci 34(2):179–185. doi:10.1016/S0148-9062(96)00063-0

Zhao J, Cai JG (2001) Transmission of elastic P-waves across single fractures with a nonlinear normal deformational behavior. Rock Mech Rock Eng 34(1):3–22. doi:10.1007/s006030170023

Zhao H, Gary G (1997) A new method for the separation of waves. Application to the SHPB technique for an unlimited duration of measurement. J Mech Phys Solids 45(7):1185–1202. doi:10.1016/S0022-5096(96)00117-2

Zhou ZL, Li XB, Ye ZY, Liu KW (2010) Obtaining constitutive relationship for rate-dependent rock in SHPB tests. Rock Mech Rock Eng 43(6):697–706. doi:10.1007/s00603-010-0096-3

Acknowledgments

This work was supported by the Chinese National Science and Technology Support Project (Nos. 2013BAB02B08, 41525009), and China Scholarship Council (CSC). The authors also would like to thank Mr. L. Goh in Monash University for his excellent assistance in test preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Li, J.C., Cai, M.F. et al. A Further Study on Wave Propagation Across a Single Joint with Different Roughness. Rock Mech Rock Eng 49, 2701–2709 (2016). https://doi.org/10.1007/s00603-016-0934-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-016-0934-z