Abstract

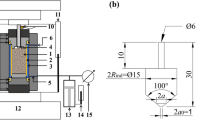

The influence of confining stress on rock breakage by a tunnel boring machine cutter was investigated by conducting sequential indentation tests in a biaxial state. Combined with morphology measurements of breaking grooves and an analysis of surface and internal crack propagation between nicks, the effects of maximum confining stress and minimum stress on indentation efficiency, crack propagation and chip formation were investigated. Indentation tests and morphology measurements show that increasing a maximum confining stress will result in increased consumed energy in indentations, enlarged groove volumes and promoted indentation efficiency when the corresponding minimum confining stress is fixed. The energy consumed in indentations will increase with increase in minimum confining stress, however, because of the decreased groove volumes as the minimum confining stress increases, the efficiency will decrease. Observations of surface crack propagation show that more intensive fractures will be induced as the maximum confining stress increases, whereas the opposite occurs for an increase of minimum confining stress. An observation of the middle section, cracks and chips shows that as the maximum confining stress increases, chips tend to form in deeper parts when the minimum confining stress is fixed, whereas they tend to formed in shallower parts as the minimum confining stress increases when the maximum confining stress is fixed.

Similar content being viewed by others

References

Alehoseein H, Detournay E, Huang H (2000) An analytical model for the indentation of rocks by blunt tools. Rock Mech Rock Eng 33(4):267–284

Bejari H, Khademi Hamidi K (2013) Simultaneous effects of joint spacing and orientation on TBM cutting efficiency in jointed rock masses. Rock Mech Rock Eng 46:897–907

Brace W (1961) Dependence of fracture strength of rocks on grain size. Bull Geol Sci Am 72(10):59–80

Carpinteri Alberto, Invernizzi Stefano (2005) Numerical analysis of the cutting interaction between indenters acting on disordered materials. Int J Fract 131:143–154

Chen LH, Labuz JF (2006) Indentation of rock by wedge-shaped tools. Int J Rock Mech Min Sci 43(7):1023–1033

Cho J, Jeon S, Jeong H et al (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54

Farrokh E, Rostami J, Laughton C (2012) Study of various models for estimation of penetration rate of hard rock TBMs. Tunn Undergr Space Technol 30:110–123

Gehring K (1995) Design criteria for TBMs with respect to real rock pressure. In: Proceedings of the tunnel boring machines: trends in design and construction of mechanized tunneling, Hagemberg, pp 43–53

Gertsch RE (2000) Rock toughness and disc cutting. University of Missouri, Rolla

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado Red Granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44(2):238–246

Gong Qiu-Ming, Zhao Jian, Jiao Yu-Yong (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 20:183–191

Gong QM, Jiao YY, Zhao J (2006a) Numerical modeling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21(1):46–55

Gong QM, Zhao J, Hefny AM (2006b) Numerical simulation of rock fragmentation process induced by two TBM cutters and cutter spacing optimization. Tunn Undergr Space Technol 21:263

Gong QM, She QR, Hou ZS, Jiang H, Peng Q (2010) Experimental study of TBM penetration in marble rock mass under high geostress. Chin J Rock Mech Eng 29(12):2522–2532 (in Chinese)

Hood M, Roxborough F (1989) Report: a review of non-explosion rock breaking. Technical report. HDRK Mining Research Ltd, Toronto

Huang H, Damjanal B, Detournay E (1998) Normal wedge indentation in rocks with lateral confinement. Rock Mech Rock Eng 31(2):81–94

Innaurato N, Oggeri C, Oreste PP, Vinai R (2007) Experimental and numerical studies on rock breaking with TBM tools under high stress confinement. Rock Mech Rock Eng 40(5):429–451

Innaurato N, Oggeri C, Oreste P, Vinai R (2011) Laboratory tests to study the influence of rock stress confinement on the performances of TBM discs in tunnels. Int J Miner Metall Mater 18(3):253–259

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge, pp 7–13

Lindqvist Per-Arne (1984) Stress fields and subsurface crack propagation of single and multiple rock indentation and disc cutting. Rock Mech Rock Eng 17:97–112

Liu HY, Kou SQ, Lindqvist PA (2002) Numerical simulation of the rock fragmentation process induced by indenters. Int J Rock Mech Min Sci 39(4):491–505

Liu Jie, Cao Ping, Li Kaihui (2015) A study on isotropic rock breaking with TBM cutters under different confining stresses. Geotech Geol Eng. doi:10.1007/s10706-015-9907-3

Ma Hongsu, Yin Lijun, Ji Hongguang (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutter. Int J Rock Mech Min Sci 48:1021–1033

Moon T, Oh J (2012) A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech Rock Eng 45:837–849

Ozdemir L, Wang FD, Snyder L (1979) Mechanical tunnel boring prediction and machine design. Colorado School of Mines Press, Colorado

Rostami J (2013) Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters. Int J Rock Mech Min Sci 57:172–186

Rostami J, Ghasemi A, Alavi Gharahbagh E, Dogruoz Cihan, Dahl Filip (2014) Study of dominant factors affecting cerchar abrasivity index. Rock Mech Rock Eng 47(5):1905–1919

Tarkoy PJ, Marconi M (1991) Difficult rock comminution and associated geological conditions. In: Proceedings of the 6th international symposium: Tunnelling’91, London, pp 195–207

Wang SY, Sloan SW, Liu HY, Tang CA (2011) Numerical simulation of the rock fragmentation process induced by two drill bits subjected to static and dynamic (impact) loading. Rock Mech Rock Eng 44:317–332

Yagiz Saffet (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Undergr Space Technol 24:66–74

Yin LJ, Gong QM, Ma HS, Zhao J, Zhao XB (2014a) Use of indentation tests to study the influence of confining stress on rock fragmentation by a TBM cutter. Int J Rock Mech Min Sci 72:261–276

Yin LJ, Gong QM, Zhao J (2014b) Study on rock mass boreability by TBM penetration test under different in situ stress conditions. Tunn Undergr Space Technol 43:413–425

Zhang ZX (2004) Estimate of loading rate for a TBM machine based on measured cutter forces. Rock Mech Rock Eng 37(3):239–248

Zhang H, Huang G, Song H, Kang Y (2012) Experimental investigation of deformation and failure mechanisms in rock under indentation by digital image correlation. Eng Fract Mech 96:667–675

Acknowledgments

This research was made possible by the National Basic Research Program of China (Project 2013CB035401), Project (51174228) supported by the National Natural Science Foundation of China and Project (71380100003) supported by Hunan Provincial Innovation Foundation for Postgraduates. The authors would like to thank the editors and reviewers for their hard work and valuable comments on this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Cao, P. & Han, D. Sequential Indentation Tests to Investigate the Influence of Confining Stress on Rock Breakage by Tunnel Boring Machine Cutter in a Biaxial State. Rock Mech Rock Eng 49, 1479–1495 (2016). https://doi.org/10.1007/s00603-015-0843-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0843-6