Abstract

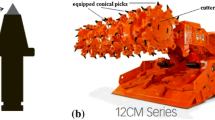

The interest in understanding the wear mechanisms of cemented carbide (CC) is not a new development. For a long time, there have been studies on different wear mechanisms under different coal/rock cutting conditions. These studies have helped improving the quality of CC, thereby preventing such wearing of tools. Due to highly unpredictable character of coal/rock, the wearing phenomena cannot be attributed to one single domain of conditions. However, one conclusion that can be drawn in this context is that, under similar working conditions, similar types of CC undergo similar nature of wearing process. An optimum combination of high wear resistance, strength and hardness has facilitated widespread application of CC in the field of mining engineering. The abrasive parts of the mining tools are made of CC materials. The current study is focussed on a detailed characterization of the wear mechanisms of conical picks, which are used for coal mining. Conical picks consist of a steel body with an inserted cone-shaped CC tip. After being used for a certain period of time, both, the CC tip and the steel body get distorted. In this study, selection of appropriate samples was followed by critical observation of them through field emission scanning electron microscopy (FESEM) and energy dispersive X-ray spectroscopy (EDS). In the previous study, we explained the distortion process of both, the tip as well as the body, using the SEM images. For the present study, two samples were taken from our previous investigation for further analysis. Three other samples were also included in the present study. Seven different types of wear mechanisms, such as, cracking and crushing, cavity formation, coal intermixing, chemical degradation along with abrasion, long and deep cracks, heating effect and body deformation were observed in the five tool samples.

Similar content being viewed by others

Abbreviations

- W:

-

Tungsten

- C:

-

Carbon

- WC:

-

Tungsten carbide

- O:

-

Oxygen

- N:

-

Nitrogen

- H:

-

Hydrogen

- Ca:

-

Calcium

- Cr:

-

Chromium

- Co:

-

Cobalt

- Ni:

-

Nickel

- Si:

-

Silicon

- S:

-

Sulphur

- Mn:

-

Manganese

- Fe:

-

Iron

- Cu:

-

Copper

- Zn:

-

Zinc

References

Aylward G, Friendly T (1994) SI chemical data, ed. P. Storer. John Wiley & Sons, Sydney

Beste U, Jacobson S (2008) A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 264:1129–1141. doi:10.1016/j.wear.2007.01.030

Beste U, Hartzell T, Engqvist H, Axen N (2001) Surface damage on cemented carbide rock drill buttons. Wear 249:324–329. doi:10.1016/S0043-1648(01)00553-1

Bilgin N, Demircin MA, Copur H, Balci C, Tuncdemir H, Akcin N (2006) Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int J Rock Mech Min Sci 43:139–156. doi:10.1016/j.ijrmms.2005.04.009

Bilgin N, Copur H, Balci C (2013) Mechanical excavation in mining and civil industries. CRC Press, Boca Raton, pp 103–123

Brookes KJA (1992) Hardmetals and Other Hard Materials. International Carbide Data, California

Brookes KJA (1996) World directory and handbook of hard metals and hard materials, 6th edn. International Carbide Data, London

Daoush WM, Lee KH, Park HS, Hong SH (2009) Effect of liquid phase composition on the microstructure and properties of (W, Ti) C Cemented carbide cutting tools. Int J Refract Metal Hard Mater 27:83–89. doi:10.1016/j.ijrmhm.2008.04.003

Deng JX, Zhou JT, Zhang H, Yan P (2011) Wear mechanisms of cemented carbide tools in dry cutting of precipitation hardening semi-austenitic stainless steels. Wear 270:520–527. doi:10.1016/j.wear.2011.01.006

Dewangan S, Chattopadhyaya S, Hloch S (2014) Wear assessment of conical pick used in coal cutting operation. Rock Mech Rock Eng. doi:10.1007/s00603-014-0680-z

Exner HE (1979) Physical and chemical nature of cemented carbides. Int Mater Rev 24:149–173. doi:10.1179/imtr.1979.24.1.149

Fish BG, Guppy GA, Ruden JT (1959) Abrasive wear effects in rotary rock drilling. Trans Inst Mining Met 63:357–383

Hochstrasser (-Kurz) S, Mueller Y, Latkoczy C, Virtanen S, Schmutz P (2007) Analytical characterization of the corrosion mechanisms of WC–Co by electrochemical methods and inductively coupled plasma mass spectroscopy. Corros Sci 49:2002–2020. doi:10.1016/j.corsci.2006.08.022

Human AM, Exner HE (1997) The relationship between electrochemical behaviour and In-Service corrosion of WC based cemented carbides. Int J Refract Metal Hard Mater 15:65–71. doi:10.1016/S0263-4368(96)00014-5

Hurt KG, Evans I (1981) Point attack tools: an evaluation of function and use for rock cutting. Inst Mining Eng 140:673–675

Jia K, Fischer TE (1996) Abrasion resistance of nanostructured and conventional cemented carbides. Wear 200:206–214. doi:10.1016/S0043-1648(96)07277-8

Kagnaya T, Boher C, Lambert L, Lazard M, Cutard T (2009) Wear mechanisms of WC-Co cutting tools from high-speed tribological tests. Wear 267:890–897. doi:10.1016/j.wear.2008.12.035

Kenny P, Johnson SN (1976) The effect of wear on the performance of mineral-cutting tools. Colliery Guardian 224:246–251

Khair AW (2001) Research and innovations for continuous miner’s cutting head for efficient cutting process of rock/coal. Department of Mining Engineering, West Virginia University, Morgantown, U.S.A. 17* International Mining Congress and Exhibition of Turkey- IMCET2001

Kindermann P, Schlund P, Sockel HG, Herr M, Heinrich W, Gorting K, Schleinkofer U (1999) High-temperature fatigue of cemented carbides under cyclic loads. Int J Refract Metal Hard Mater 17:55–68. doi:10.1016/S0263-4368(99)00014-1

King RB (1994) Encyclopedia of inorganic chemistry, vol 2. Wiley, Chichester

Lagerquist M (1975) A study of the thermal fatigue crack propagation in WC–Co cemented carbide. Powder Met 18:71–88. doi:10.1179/pom.1975.18.35.006

Larsen-basse J (1985) Binder extrusion in sliding wear of WC–Co alloys. Wear 105:247–256. doi:10.1016/0043-1648(85)90071-7

Lee HC, Gurland J (1978) Hardness and deformation of cemented tungsten carbide. Mater Sci Eng 33:125–133. doi:10.1016/0025-5416(78)90163-5

MacGregor IM, Baker RH, Luyckx SB (1990) A comparison between the wear of continuous miner button picks and the wear of pointed picks used in South African Collieries. Mining Sci Technol 11:213–222. doi:10.1016/0167-9031(90)90423-P

Mary D, Gonseth DR (1993) A new look at carbide tool life. Wear 165:9–17. doi:10.1016/0043-1648(93)90366-T

Miller MH, Sikarskie DL (1968) On the penetration of rock by three-dimensional indentors. Int J Rock Mech Mining Sci Geomech Abstract 5:375–398. doi:10.1016/0148-9062(68)90043-0

Milman YuV, Chugunova S, Goncharuck V (1997) Low and high temperature hardness of WC-6 wt% Co alloys. Int J Refract Metal Hard Mater 15:97–101. doi:10.1016/S0263-4368(97)81231-0

Pirso J, Letunovits S, Viljus M (2004) Friction and wear behaviour of cemented carbides. Wear 257:257–265. doi:10.1016/j.wear.2003.12.014

Plis MN, Wingquist CF, Roepke WW (1988) Preliminary evaluation of the relationship of bit wear to cutting distance, forces and dust using selected commercial and experimental coal and rock cutting tools. Bureau of Mines, Michigan

Rajput RK (2007) A text book of manufacturing technology: manufacturing processes, Firewall Media, p 407

Tomlinson WJ, Linzell CR (1988) Anodic polarization and corrosion of cemented carbides with cobalt and nickel binders. J Mater Sci 23:914–918. doi:10.1007/BF01153988

Tulhoff H (2000) Carbides. Metal like carbides of industrial importance. Ullmann’s encyclopedia of industrial chemistry. Wiley, VHC. doi:10.1002/14356007.a05_061

Voorhies JD (1972) Electrochemical and chemical corrosion of tungsten carbide (WC). J Electrochem Soc 119:219–222. doi:10.1149/1.2404164

Wood GA (1970) Quality control in the hard-metal industry. Powder metallurgy 13:338–365. doi:10.1179/pom.1970.13.26.015

Yilmaz NG, Yurdakul M, Goktan RM (2007) Prediction of radial bit cutting force in high-strength rocks using multiple linear regression analysis. Int J Rock Mech Min Sci 44:962–970. doi:10.1016/j.ijrmms.2007.02.005

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dewangan, S., Chattopadhyaya, S. Characterization of Wear Mechanisms in Distorted Conical Picks After Coal Cutting. Rock Mech Rock Eng 49, 225–242 (2016). https://doi.org/10.1007/s00603-015-0726-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0726-x