Abstract

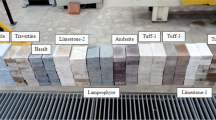

In this paper, an experimental study on the cut depth, which is an important cutting performance indicator in the abrasive waterjet (AWJ) cutting of rock, was presented. Taguchi experimental design of an orthogonal array was employed to conduct the experiments. A variety of nine types of granitic rocks were used in the cutting experiments. The experimental data were used to assess the influence of AWJ operating variables on the cut depth. Using regression analysis, models for prediction of the cut depth from the operating variables and rock properties in AWJ machining of granitic rocks were then developed and verified. The results indicated that the cut depths decreased with increasing traverse speed and decreasing abrasive size. On the other hand, increase of the abrasive mass flow rate and water pressure led to increases in the cut depths. Additionally, it was observed that the standoff distance had no discernible effects on the cut depths. Furthermore, from the statistical analysis, it was found that the predictive models developed for the rock types had potential for practical applications. Verification of the models for using them as a practical guideline revealed a high applicability of the models within the experimental range used.

Similar content being viewed by others

References

Adnani A, Basri M, Malek EA, Salleh AB, Rahman MBA, Chaibakhsh N, Abdul-Rahman RNZRA (2010) Optimization of lipase-catalyzed synthesis of xylitol ester by Taguchi robust design method. Ind Crop Prod 31:350–356

Agus M, Bortolussi A, Ciccu R, Kim WM, Manca PP (1993) The influence of rock properties on waterjet performance. In: Proceedings of the 7th American water jet conference, Seattle, Washington, USA, August 1993, pp 427–442

Asiltürk İ, Akkuş H (2011) Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 44:1697–1704

Atici U, Ersoy A (2009) Correlation of specific energy of cutting saws and drilling bits with rock brittleness and destruction energy. J Mater Process Technol 209:2602–2612

Aydin G, Karakurt I, Aydiner K (2010) Investigation of effect of the process parameters on granite kerf angle in abrasive waterjet cutting. J Chambers Min Eng Turk 49(2):17–26 (in Turkish)

Aydin G, Karakurt I, Aydiner K (2011) An investigation on the surface roughness of the granite machined by abrasive waterjet. Bull Mater Sci 34(4):985–992

Buyuksagis SI (2007) Effect of cutting mode on the sawability of granites using segmented circular diamond sawblade. J Mater Process Technol 183:399–406

Chen L, Siores E, Wong WCK (1996) Kerf characteristics in abrasive waterjet cutting of ceramic materials. Int J Mach Tool Manuf 36(11):1201–1206

Duflou JR, Kruth J-P, Bohez EL (2001) Contour cutting of pre-formed parts with abrasive waterjet using 3-axis nozzle control. J Mater Process Technol 115:38–43

Guo NS, Louis H, Meier G (1993) Surface structure and kerf geometry in abrasive waterjet cutting: formation and optimization. In: Proceedings of the 7th American waterjet conference, Seattle, Washington, USA, August 1993, pp 1–27

Hasçalık A, Çaydaş U (2008) Optimization of turning parameters for surface roughness and tool life based on the Taguchi method. Int J Adv Manuf Technol 38:896–903

Hashish M (1984) A modeling study of metal cutting with abrasive waterjets. J Eng Mater Technol 106:88–100

Hashish M (1989) Pressure effects in abrasive-waterjet (AWJ) machining. J Eng Mater Technol 111:221–228

Hashish M (1991) Optimization factors in abrasive-waterjet machining. J Eng Ind 113:29–37

Hlaváč LM, Hlaváčova IM, Gembalová L, Kaličinský J, Fabian S, Měšťánek J, Kmec J, Mádr V (2009) Experimental method for the investigation of the abrasive water jet cutting quality. J Mater Process Technol 209(20):6190–6195

Karakurt I, Aydin G, Aydiner K (2012) An experimental study on the depth of cut of granite in abrasive waterjet cutting. Mater Manuf Process 27(5):538–544

Kovacevic R (1992) Monitoring the depth of abrasive waterjet penetration. Int J Mach Tool Manuf 32(5):725–736

Lin T-R (2002) Optimisation technique for face milling stainless steel with multiple performance characteristics. Int J Adv Manuf Technol 19:330–335

Miranda RM, Quintino L (2005) Microstructural study of material removal mechanisms observed in abrasive waterjet cutting of calcareous stones. Mater Charact 54(4–5):370–377

Miranda RM, Lousa P, Mouraz MAJ, Kim T (1993) Abrasive waterjet cutting of Portuguese marbles. In: Proceedings of the 7th American water jet conference, Seattle, Washington, USA, August 1993, pp 443–457

Momber AW, Kovacevic R (1997) Test parameter analysis in abrasive water jet cutting of rocklike materials. Int J Rock Mech Min Sci 34(1):17–25

Summers DA (1995) Waterjetting technology. E&FN Spon, London

Wang J (1999) Abrasive waterjet machining of polymer matrix composites—cutting performance, erosive process and predictive models. Int J Adv Manuf Technol 15:757–768

Wang J (2007) Predictive depth of jet penetration models for abrasive waterjet cutting of alumina ceramics. Int J Mech Sci 49(3):306–316

Wang J (2009) A new model for predicting the depth of cut in abrasive waterjet contouring of alumina ceramics. J Mater Process Technol 209(5):2314–2320

Wang J, Guo DM (2002) A predictive depth of penetration model for abrasive waterjet cutting of polymer matrix composites. J Mater Process Technol 121:390–394

Zeng J, Kim TJ (1996) An erosion model of polycrystalline ceramics in abrasive waterjet cutting. Wear 193(2):207–217

Zhang JZ, Chen JC, Kirby ED (2007) Surface roughness optimization in an end-milling operation using the Taguchi design method. J Mater Process Technol 184:233–239

Acknowledgments

The authors would like to express their sincere thanks and appreciation for the financial support to TÜBİTAK (The Scientific and Technological Research Council of Turkey) (Project No. 108M370).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aydin, G., Karakurt, I. & Aydiner, K. Prediction of the Cut Depth of Granitic Rocks Machined by Abrasive Waterjet (AWJ). Rock Mech Rock Eng 46, 1223–1235 (2013). https://doi.org/10.1007/s00603-012-0307-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-012-0307-1