Abstract

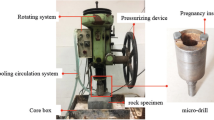

Mining and petroleum drill bits are subjected to highly abrasive rock and high-velocity fluids that cause severe wear and erosion in service. To augment the rate of penetration and minimize the cost per foot, such drill bits are subjected to increasing rotary speeds and weight. A rotary/percussive drill typically hits the rock 50 times per second with hydraulic impact pressure of about 170–200 bar and feed pressure of about 90–100 bar, while rotating at 75–200 rpm. The drill rig delivers a high-velocity flow of drilling fluid onto the rock surface to dislodge cuttings and cool the bit. The impingement of high-velocity drilling fluid with entrained cuttings accelerates the erosion rate of the bit. Also, high service temperature contributes to softening of the rock for increased penetration. Hence, there is a need to optimize the drilling process and balance the wear rate and penetration rate simultaneously. This paper presents an experimental scanning electron microscopy (SEM) study of electroplated (nickel-bonded) diamond drills for different wear modes.

Similar content being viewed by others

References

Beste U et al (2001) Surface damage on cemented carbide rock-drill buttons. Wear 249:324–329

Beste U et al (2003) Micro scale hardness distribution of rock types related to rock drill wear. Wear 254:1147–1154

Beste U, Jacobson S, Hogmark S (2008a) Rock penetration into cemented carbide drill buttons during rock drilling. Wear 264:1142–1151

Beste U, Jacobson S, Hogmark S (2008b) Rock penetration into cemented carbide drill buttons during rock drilling. Wear 264:1142–1151

Ersoy A et al (2005) Wear characteristics of circular diamond saws in the cutting of different hard abrasive rocks. Wear 258:1422–1436

Hogmark S et al (2008) Rock penetration in to cemented carbide drill buttons during rock drilling. Wear 264:1142–1151

Jacobson S et al (2008) A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 264:1129–1141

Kahraman S et al (2004) Predicting the sawability of carbonate rocks using curvilinear regression analysis. Int J Rock Mech Min Sci 41:1123–1131

Lundvall A et al (2004) Micro-scratch evaluation of rock types-a means to comprehend rock drill wear. Tribol Int 37:203–210

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, A., Chattopadhyaya, S. & Hloch, S. Critical Investigation of Wear Behaviour of WC Drill Bit Buttons. Rock Mech Rock Eng 46, 169–177 (2013). https://doi.org/10.1007/s00603-012-0255-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-012-0255-9