Abstract

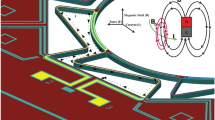

Magnetic microactuator construction has benefited from two processing extensions: stacking in the vertical and horizontal direction and multiple X-ray mask sacrificial layer LIGA. Vertical stacking requires height control of electroplated structures. This has been achieved by material insensitive lapping and polishing techniques. Structural heights of more than 1 mm have been achieved with 300 μm low-energy exposures. This has resulted in actuators with output forces to 100 mN and throws to 2 mm.

Re-planarization after electroplating without photoresist damage enables second layer photoresist application via solvent bonding and fly cutting. Exposure of the substrate with a second X-ray mask becomes useful if the second mask can be aligned to the substrate. This has been accomplished with sufficient accuracy via mechanical techniques.

A variety of magnetic actuators have been constructed. All of them use assembled rather than integrated coils. The performance of the assembled coils is adequate for position sensing in linear actuators and has resulted in a closed loop control device.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 25 August 1997 / Accepted: 3 November 1997

Rights and permissions

About this article

Cite this article

Guckel, H. Progress in magnetic microactuators. Microsystem Technologies 5, 59–61 (1998). https://doi.org/10.1007/s005420050141

Issue Date:

DOI: https://doi.org/10.1007/s005420050141