Abstract

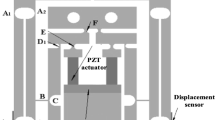

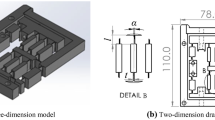

This paper presents the design and analysis of a novel piezoelectric-actuated compliant microgripper that mainly consists of a three-stage amplifier and a pair of parallelogram mechanism to achieve a large amplification ratio and a wide motion stroke. The three stages are configured as two bridge-type with one lever-type amplification mechanism, and a pair of parallelogram mechanisms are integrated into the lever-type amplification mechanism to provide advantages in terms of parallel gripping and large amplification ratio. The crucial structural parameters are optimized by the response surface optimization. The static model of the microgripper is established and finite element analysis is conducted to evaluate the characteristics of the microgripper. The performance of the microgripper is investigated by experimental studies on a fabricated prototype. Experimental results show that the microgripper obtains a large displacement amplification ratio of 45.58, a wide motion stroke of 683.70 μm, and it can successfully grasp different copper wires with diameters of 300 μm and 500 μm.

Similar content being viewed by others

Abbreviations

- c ij :

-

The flexibility coefficient

- C :

-

The compliance matrix

- D(Z):

-

The displacement of one jaw

- E :

-

The elastic modulus

- E(Z):

-

The natural frequency of the microgripper

- F in1 :

-

The input force of the first-stage amplifier

- F out1 :

-

The output force of the first-stage amplifier

- F :

-

The loading vector

- G :

-

The shear modulus

- h :

-

Height of the rectangular hinge

- l 1 :

-

Length of the bridge arm in first-stage

- l 2 :

-

Length of the bridge arm in second-stage

- l 31 :

-

Length of the short arm in third-stage

- l 32 :

-

Length of the long arm in third-stage

- l α :

-

The linear distance between the two hinges

- N :

-

The objective function 2

- r :

-

Length of the rectangular hinge

- R :

-

The DAR of the microgripper

- R 1 :

-

The DAR of the first-stage amplifier

- R 2 :

-

The DAR of the second-stage amplifier

- R 3 :

-

The DAR of the third-stage amplifier

- S :

-

The objective function 1

- t :

-

Width of the rectangular hinge

- X in :

-

The input displacement of the microgripper

- X out :

-

The output stroke of the microgripper

- X :

-

The displacement vector

- Z :

-

A vector of structural parameters

- α :

-

The angle between two adjacent flexure hinges

- Δx 1 :

-

The input displacements of the chosen arm

- Δy 1 :

-

The output displacements of the chosen arm

- Δx h :

-

The translational deformations of the flexure hinges A and B in x directions

- Δy h :

-

The translational deformations of the flexure hinges A and B in y directions

- MEMS:

-

Microelectromechanical systems

- PZT:

-

Piezoelectric

- DAR:

-

Displacement amplification ratio

- SR:

-

Scott-Russell

- FEM:

-

Finite element method

- RSM:

-

Response surface methodology

References

Alogla A, Amalou F, Scanlan P et al (2014) Development of a pneumatically actuated cantilever based micro-tweezer. Proc Eng 87:1390–1393

Chabani I, Mebarek-Oudina F, Aissa (2022) A MHD flow of a hybrid nano-fluid in a triangular enclosure with zigzags and an elliptic obstacle. Micromachines 13(2):224

Chen W, Zhang X, Fatikow S et al (2017) Design, modeling and test of a novel compliant orthogonal displacement amplification mechanism for the compact micro-grasping system. Microsyst Technol 23:2485–2498

Chen W, Lu Q, Kong C et al (2019) Design, analysis and validation of the bridge-type displacement amplification mechanism with circular-axis leaf-type flexure hinges for micro-grasping system. Microsyst Technol 25:1121–1128

Chen X, Deng Z, Hu S et al (2020) Designing a novel model of 2-DOF large displacement with a stepwise piezoelectric-actuated microgripper. Microsyst Technol 27:2809–2816

Das T, Shirinzadeh B, Ghafarian M et al (2009) A flexure-based 2-DOF microgripper for handling micro-objects [C]. In: Proc. of 2018 International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), pp 1–6

Das TN, Shirinzadeh B, Al-Jodah A et al (2021) A novel compliant piezoelectric actuated symmetric microgripper for the parasitic motion compensation. Micromachines 155:104069

Fares R, Mebarek-Oudina F, Aissa A et al (2021) Optimal entropy generation in Darcy-Forchheimer magnetized flow in a square enclosure filled with silver based water nanoliquid. J Therm Anal Calorim 147:1571–1581

Garces M, Zimmermann T, Siemers C et al (2019) Shape memory alloy actuators for silicon microgrippers. J Microelectromech Syst 28(5):869–881

Grossard M, Rotinat-Libersa C, Chaillet N et al (2009) Mechanical and control-oriented design of a mono-lithic piezoelectric microgripper using a new topological optimization method. IEEE/ASME Trans Mechatron 14(1):32–45

Gu G, Zhu L, Su C et al (2015) Proxy-based sliding-mode tracking control of piezoelectric-actuated nanopositioning stages. IEEE/ASME Trans Mechatron 20(4):1956–1965

Hao Y, Wang C, Sun Z et al (2021) Rotatory microgripper based on a linear electrostatic driving scheme. Microelectron Eng 248(15):111601

Ho NL, Dao T, Chau N et al (2019) Multi-objective optimization design of a compliant microgripper based on hybrid teaching learning-based optimization algorithm. Microsyst Technol 25:2067–2083

Koseki Y, Tanikawa T, Koyachi N et al (2001) Kinematic analysis of a translational 3-d.o.f. micro-parallel mechanism using the matrix method. Adv Robot 16(3):251–264

Liang C, Wang F, Tian Y et al (2015) A novel monolithic piezoelectric actuated flexure-mechanism based wire clamp for microelectronic device packaging. Rev Sci Instrum 86:045106

Liu P, Yan P (2016) A new model analysis approach for bridge-type amplifiers supporting nano-stage design. Mech Mach Theory 99:176–188

Lyu Z, Xu Q (2021) Recent design and development of piezoelectric-actuated compliant microgrippers: a review. Sens Actuators A 331:113002

Lyu Z, Xu Q (2023) Design of a new bio-inspired dual-axis compliant micromanipulator with millimeter strokes. IEEE Trans Rob 39(1):470–484

Mehrabi H, Hamedi M, Aminzahed I (2020) A novel design and fabrication of a micro-gripper for manipulation of micro-scale parts actuated by a bending piezoelectric. Microsyst Technol 27:2809–2816

Qi K, Xiang Y, Fang C et al (2015) Analysis of the displacement amplification ratio of bridge-type mechanism. Mech Mach Theory 87:45–46

Qian J, Yan P, Liu P (2021) Position/force modeling and analysis of a piezo-driven compliant micro-gripper considering the dynamic impacts of gripping objects. Smart Mater Struct 30:075036

Roy A, Nabi M (2021) Modeling of MEMS electrothermal microgripper employing POD-DEIM and POD method. Microelectron Reliab 125:114338

Shi C, Dong X, Yang Z (2021) A microgripper using piezoelectric actuation for micro-object manipulation. IEEE/ASME Trans Mechatron 26(6):3076–3086

Sun X, Chen W, Fatikow S et al (2015) A novel piezo-driven microgripper with a large jaw displacement. Microsyst Technol 21:931–942

Wang D, Yang Q, Dong H (2011) A monolithic compliant piezoelectric-driven microgripper: design, modeling, and testing. IEEE/ASME Trans Mechatron 18(1):138–147

Wang F, Liang C, Tian Y et al (2015) Design of a piezoelectric-actuated microgripper with a three-stage flexure-based amplification. IEEE/ASME Trans Mechatron 20(5):2205–2213

Wang F, Shi B, Huo Z et al (2021) Control and dynamic releasing method of a piezoelectric actuated microgripper. Precis Eng 68:1–9

Wu Z, Li Y (2021) Design and control of a novel micro-gripper using adaptive backstepping slide mode control method. Microsyst Technol 27:4227–4239

Wu Z, Xu Q, Ai N et al (2023) Design of a novel magnetically actuat-ed biaxial robot with compact structure and easy operation. IEEE Robot Autom Lett. https://doi.org/10.1109/LRA.2023.3274428

Yang Y, Wei Y, Lou J et al (2015) A new piezo-driven microgripper based on the double-rocker mechanism. Smart Mater Struct 24:075031

Acknowledgements

This research work was supported by the National Natural Science Foundation of China (51805327).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Z., Ma, H., Li, Q. et al. Design and analysis of a compliant microgripper with a large amplification ratio. Microsyst Technol 29, 1333–1341 (2023). https://doi.org/10.1007/s00542-023-05505-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-023-05505-x