Abstract

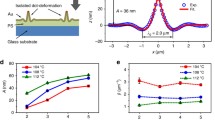

Micro-pyramid functional surfaces are currently widely used in various advanced scientific, technological, industrial, and engineering fields with their excellent performances of compactness, light weight and higher heat transfer performance. Many recent studies have introduced micro cutting as a method to achieve high-quality micro pyramid surfaces. This paper concerns a micro-pyramid with a height and slope of 60 μm and 30°. Firstly, numerical simulation of the optical effect related to micro-pyramid surfaces was carried out to reveal the mechanism of functional surface imaging and its typical and potential applications. The simulated optical effect shows that the micro-pyramid can form four virtual images on the same side of an object. Next, a novel and simple fabrication method for micro-pyramidal structures was developed by using cross cutting with a 120° V-tip diamond tool by ultra-precision raster milling (UPRM), which can obtain good surface quality, high form accuracy and efficient productivity in contrast to grinding, laser machining and etching. Finally, precision injection molding was employed to replicate a micro-pyramid on the PMMA for optical testing. Although the quality of molded micro pyramid pattern decreased, optical testing showed that clear images were obtained, and the experimental results were consistent with the simulation results.

Similar content being viewed by others

References

Brinksmeier E, Preuss W (2012) Review micro-machining. Philos Trans R Soc Lond A 370:3973

Cutting M (2013) Fundamentals and applications. Wiley, Chichester

Guo P, Lu Y, Ehmann KF, Cao J (2014) Generation of hierarchical micro- structures for anisotropic wetting by elliptical vibration cutting. CIRP Ann Manuf Technol 63:553

Janik M, Koba M, Celebańska A, Bock WJ, Śmietana M (2018) Sensing properties of micro-cavity in-line Mach-Zehnder interferometer enhanced by reactive ion etching. Opt Laser Technol 103:260

Jiao FF, Saravi SS, Cheng K (2017) Investigation on an integrated approach to design and micro fly-cutting of micro-structured riblet surfaces. Proc Inst Mech Eng Part C J Mech Eng Sci 231(18):3291

Kim JW, Plachetka U, Moormann C, Kurz H (2013) Fabrication of inverse micro/nano pyramid structures using soft UV-NIL and wet chemical methods for residual layer removal and Si-etching. Microelectron Eng 110:403

Lee DG, Pyo DS, Cho CS, Kim BW (2016) Effects on micropyramid and nanoneedle structures for superhydrophobicity on Si surface. Vacuum 131:188

Li W, Zhai Y, Yi P, Zhang Y (2016) Fabrication of micro-pyramid arrays on PETG films by roll-to-roll hot embossing. Microelectron Eng 164:100

Niu ZC, Jiao FF, Cheng K (2018) An innovative investigation on chip formation mechanisms in micro-milling using natural diamond and tungsten carbide tools. J Manuf Process 31(1):382

Sánchez JC, Toro A, Estupiñán HA, Leighton GJT, Endrino JL (2020) Fabrication of bio-inspired deterministic surfaces by photochemical machining for tribological applications. Tribol Int 150:341

Sodtke C, Stephan P (2007) Spray cooling on micro structured surfaces. Int J Heat Mass Transf 50:4089

Wang HT, Lee WB (2016) A study of cutting factors affecting the generation of functional hierarchical rib array structure in ultra-precision raster milling. Int J Adv Manuf Technol 86:989

Wang HT, Lee WB, Chan J, To S (2015) Numerical and experimental analysis of heat transfer in turbulent flow channels with two-dimensional ribs. Appl Therm Eng 75:623

Wu H, Gao J, Yi PY, Peng LF, Lai XM (2017) Investigation of reflective performance for micro-pyramid arrays by roll-to-roll UV imprinting process. Microelectron Eng 182:61

Xie J, Deng ZJ, Liao JY, Li N, Zhou H, Ban WX (2016) Study on a 5-axis precision and mirror grinding of glass freeform surface without on-machine wheel-profile truing. Int J Mach Tool Manufact 109:65

Yan J, Yoshino M, Kuriagawa T, Shirakashi T, Syoji K, Komanduri R (2001) On the ductile machining of silicon for micro electro-mechanical systems (MEMS), opto-electronic and optical applications. Mater Sci Eng A 297:230

Yuan JL, Liu BH, Hang W, Deng QF (2017) Review on the progress of ultra-precision machining technologies. Front Mech Eng 12:158

Zhang SJ, To S, Zhu ZW, Zhang GQ (2016) review of fly cutting applied to surface generation in ultra-precision machining. Int J Mach Tool Manufact 103:13

Zhang SJ, Zhou YP, Zhang HJ, Xiong ZW, To S (2019) Advances in ultra-precision machining of micro-structured functional surfaces and their typical applications. Int J Mach Tool Manufact 142:16

Zhao Y, Zhao H, Lv RQ, Zhao J (2019) Review of optical fiber Mach-Zehnder interferometers with micro-cavity fabricated by femtosecond laser and sensing applications. Opt Laser Eng 117:7

Zhu ZW, To S, Zhang SJ (2015) Theoretical and experimental investigation on the novel end-fly-cutting-servo diamond machining of hierarchical micro-nanostructures. Int J Mach Tool Manufact 94:15

Acknowledgements

The work described in this paper is partially supported by Science and Technology Planning project of Shenzhen Municipality (JCYJ20170818135756874) , the Shenzhen Polytechnic research Funds (601822K21017). Guangdong Provincial Department of Education Characteristic Innovation Fund (6019210024K).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, H., Chen, W., Zhao, W. et al. Numerical and experimental study on the optical performance of micro-pyramid functional surfaces. Microsyst Technol 27, 2671–2678 (2021). https://doi.org/10.1007/s00542-020-05055-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-05055-6