Abstract

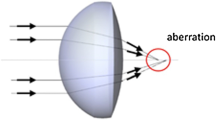

Injection molding is an ideal technique for the low-cost mass production of plastic optical lenses. However, the optical quality of the lens is significantly dependent on the processing parameters employed in the molding process. In particular, the parameters should be set in such a way as to minimize both the shrinkage displacement-induced warpage (in order to reduce optical aberrations) and the residual stress (in order to reduce the birefringence). However, in practice, the two performance targets are mutually exclusive. That is, a smaller warpage results in a greater residual stress, and vice versa. Thus, in the present study, Taguchi experiments are first performed to determine the processing parameters which individually minimize the warpage and retardation of a symmetric plastic double-convex Fresnel lens, respectively. A grey relational analysis technique is then applied to the Taguchi results to establish the processing parameters which achieve the optimal tradeoff between the two performance objectives. The validity of the proposed method is demonstrated by means of mold-flow analysis simulations. The results show that in simultaneously optimizing both the warpage and the retardation, the injection molding control factors are ranked in order of decreasing influence as follows: packing pressure, packing time, melt temperature, filling time, cooling time and mold temperature. Given the optimal process parameter settings, the warpage and retardation are reduced by 16.42% and 74.74%, respectively, compared to the original design. In other words, the proposed grey-based Taguchi method provides a viable technique for optimizing both performance targets for the considered double-convex Fresnel lens.

Similar content being viewed by others

References

Aben H, Guillermet C (1993) Photoelasticity of glass. Springer, Berlin

Beaumont JP (2004) Runner and gating design handbook: tools for successful injection molding. Hanser Gardner Publications, Cincinnati

Bourgade T, Asundi A (2016) Residual stress measurement for injection molded components, 2016.04

Bower AF (2009) Applied mechanics of solids. CRC Press, Taylor & Francis Group, Boca Raton

Chen Y, Yi AY, Su L, Klocke F, Pongs G (2008) Numerical simulation and experimental study of residual stresses in compression molding of precision glass optical components. J Manuf Sci Eng 130(5):051012

Cosby RM (1977) The linear Fresnel lens solar concentrator: trans- verse tracking error effects. NASA CR-2889 National Aeronautics and Space Administration Washington, p 20546

Deng Julong (1982) Control problems of grey systems. Syst Control Lett 5:288–294

Fischer JM (2013) Handbook of molded part shrinkage and warpage, 2nd edn. Elsevier, Amsterdam

Hsia KH, Wu JH (1998) A study on the data preprocessing in grey relation analysis. J Chin Grey Syst 1:47–54

Lin CM, Chen YW (2019) Grey optimization of injection molding processing of plastic optical lens based on joint consideration of aberration and birefringence effects. Microsyst Technol 25:621–631

Lin CM, Hsieh HK (2017) Processing optimization of Fresnel lenses manufacturing in the injection molding considering birefringence effect. Microsyst Technol 23:5689–5695

Lin CM, Tan CM, Wang CK (2013) Gate design optimization in the injection molding of the optical lens. Optoelectron Adv Mater Rapid Commun 7:580–584

Lu X, Khim LS (2001) A statistical experimental study of the injection molding of optical lenses. J Mater Process Technol 113:189

Rao RS, Prakasham RS, Prasad KK, Rajesham S, Sarma PN, Rao LV (2004) Xylitol production by Candida sp.: parameter optimization using Taguchi approach. Process Biochem 39:951

Rao RS, Kumar CG, Prakasham RS, Hobbs PJ (2008) The Taguchi methodology as a statistical tool for biotechnological applications: a critical appraisal. J Biotechnol 3:510

Rosa JL, Robin A, Silva MB, Baldan CA, Peres MP (2009) Electrodeposition of copper on titanium wires: Taguchi experimental design approach. J Mater Process Technol 209:1181–1188

Acknowledgements

The authors gratefully acknowledge the financial support provided to this study by the Ministry of Science and Technology of Taiwan, ROC, under Grant Numbers MOST 105-2815-C-415-014-E and MOST 105-2221-E-415-004.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, CM., Chen, WC. Optimization of injection-molding processing conditions for plastic double-convex Fresnel lens using grey-based Taguchi method. Microsyst Technol 26, 2575–2588 (2020). https://doi.org/10.1007/s00542-020-04798-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-04798-6