Abstract

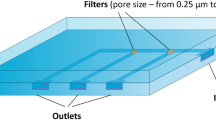

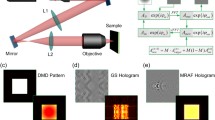

Many decades have seen the exploration of a novel methodology for developing microstructure in Microfluidic devices. Despite many methodologies, femtosecond laser technique has been a rising method in the conspicuous way of developing microstructures through direct write method which provides an ease of fabrication. For fabrication precise microstructure in semiconductor devices such as silicon, the femtosecond laser is preferred. An array of micro-holes has been created in monocrystalline silicon (100) using femtosecond laser ablation with multiple pulses. An investigation is carried out for obtaining the minimum diameter holes by varying the power for multiple pulses. The fabricated microhole array find its application in cancer cell separation from human blood.

Similar content being viewed by others

References

Ali JMY, Shanmugam V, Lim B, Aberle AG, Mueller T (2018) Femtosecond laser ablation of dielectric layers for high-efficiency silicon wafer solar cells. Sol Energy 164:287–291

Challa PK, Peter Q, Wright MA, Zhang Y, Saar KL, Carozza JA, Benesch JL, Knowles TP (2018) Real-time intrinsic fluorescence visualization and sizing of proteins and protein complexes in microfluidic devices. Anal Chem 90(6):3849–3855

Dobrzański LA, Drygała A, Gołombek K, Panek P, Bielańska E, Zięba P (2008) Laser surface treatment of multicrystalline silicon for enhancing optical properties. J Mater Process Technol 201(1-3):291–296

Gedvilas M, Indrišiūnas S, Voisiat B, Stankevičius E, Selskis A, Račiukaitis G (2018) Nanoscale thermal diffusion during the laser interference ablation using femto-, pico-, and nanosecond pulses in silicon. Phys Chem Chem Phys 20(17):12166–12174

Hoi H, Rezaie SS, Gong L, Sen P, Zeng H, Montemagno C, Gupta M (2018) Biofunctionalized silicon nitride platform for sensing applications. Biosens Bioelectron 102:497–503

Indhu R, Radha S, Manikandan E et al (2018) Micromachining of biocompatible polymer substrate for cancer cell separation applications. Microsyst Technol. https://doi.org/10.1007/s00542-018-4073-1

Jiao L, Ng EYK, Zheng H, Wee LM (2011) Statistical analysis of femtosecond pulses laser on hole drilling of silicon wafer. Surf Rev Lett 18(1 & 2):39–45

Juskova P, Ollitrault A, Serra M, Viovy JL, Malaquin L (2018) Resolution improvement of 3D stereo-lithography through the direct laser trajectory programming: application to microfluidic deterministic lateral displacement device. Anal Chim Acta 1000:239–247

Kaakkunen JJJ, Paivasaari K, Vahimaa P (2011) Fabrication of large-area hole arrays using high-efficiency two-grating interference system and femtosecond laser ablation. Appl Phys A 103:267–270

Liao C, Anderson W, Antaw F, Trau M (2018) Maskless 3D ablation of precise microhole structures in plastics using femtosecond laser pulses. ACS Appl Mater Interfaces 10(4):4315–4323

Ma ZC, Zhang YL, Han B, Chen QD, Sun HB (2018) Femtosecond‐laser direct writing of metallic micro/nanostructures: from fabrication strategies to future applications. Small Methods. https://doi.org/10.1002/smtd.201700413

Malek CGK (2006) Laser processing for bio-microfluidics applications (part II). Anal Bioanal Chem 385(8):1362–1369

McDonnell C, Milne D, Prieto C, Chan H, Rostohar D, O’Connor GM (2015) Laser patterning of very thin indium tin oxide thin films on PET substrates. Appl Surf Sci 359:567–575

Molotokaitė E, Gedvilas M, Račiukaitis G, Girdauskas V (2010) Picosecond laser beam interference ablation of thin metal films on glass substrate. J Laser Micro/Nanoeng 5(1):74–79

Shaegh SAM, Pourmand A, Nabavinia M, Avci H, Tamayol A, Mostafalu P, Ghavifekr HB, Aghdam EN, Dokmeci MR, Khademhosseini A, Zhang YS (2018) Rapid prototyping of whole-thermoplastic microfluidics with built-in microvalves using laser ablation and thermal fusion bonding. Sens Actuators B Chem 255:100–109

Singh SS, Baruah PK, Khare A, Joshi SN (2018) Effect of laser beam conditioning on fabrication of clean micro-channel on stainless steel 316L using second harmonic of Q-switched Nd: YAG laser. Opt Laser Technol 99:107–117

Voisiat B, Gedvilas M, Indrišiūnas S, Račiukaitis G (2011) Flexible microstructuring of thin films using multi-beam interference ablation with ultrashort lasers. J Laser Micro/Nanoeng 6(3):185–190

Wang D, Wang Z, Zhang Z, Yue Y, Li D, Maple C (2013) Direct modification of silicon surface by nanosecond laser interference lithography. Appl Surf Sci 282:67–72

Wang R, Peichao W, Zhan Z, Bing X, Yanlei H, Zhu W, Li J, Chu J, Dong W, Li G (2018) High quality microhole array by water assisted femtosecond laser perforating for improved particle sorting. Opt Eng 57(5):056114

Yaowei H, Wang Z, Weng Z, Miao Yu, Wang D (2016) Bio-inspired hierarchical patterning of silicon by laser interference lithography. Appl Opt 55(12):3226–3232

Zeng X, Mao XL, Greif R, Russo RE (2005) Experimental investigation of ablation efficiency and plasma expansion during femtosecond and nanosecond laser ablation of silicon. Appl Phys A 80(2):237–241

Zhang C, Yao J, Lan S, Trofimov VA, Lysak TM (2013) Effects of plasma confinement on the femtosecond laser ablation of silicon. Opt Commun 308:54–63

Zhao J, Huettner B, Menschig A (2001) Microablation with ultrashort laser pulses. Opt Laser Technol 33:487–491

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Indhu, R., Radha, S., Manikandan, E. et al. Fabrication of silicon microstructure for cell separation using ultrashort laser ablation. Microsyst Technol 25, 2931–2936 (2019). https://doi.org/10.1007/s00542-018-4233-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-4233-3