Abstract

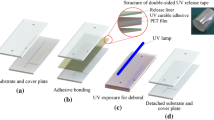

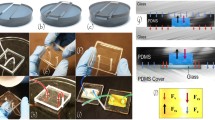

Dry film has been widely used as a low-cost photoresist in the print circuit board industry which consists of a thin layer of photoresist sandwiched between two protective polymer layers. In this research, a simple, cleanroom-free, low-cost and highly adaptable bonding method for various polymer and glass-based microfluidic systems was proposed using the cross-linked dry film photoresist. In this proposed approach, the uncross-linked dry film photoresist was sandwiched between substrates and cover plate, then using UV exposure for the crosslinking of the photoresist to reach a secured bonding, after bonding, a cleaning process for the removal of photoresist residuals trapped inside the microchannels was also applied. The proposed bonding method is highly adaptable for different kinds of polymer or glass-based microfluidic devices, even the hybrid bonding between polymer and glass substrates could be achieved, which is usually very challenging using the conventional bonding technologies. Comparing with the traditional adhesive bonding method, the proposed method is simple, low-cost and without the requirement for toxic organic solvents, in addition, the cleaning procedure proposed in this study could effectively remove the residual of the adhesives trapped in the microchannels.

Similar content being viewed by others

References

Bhattacharjee N, Urrios A, Kang S, Folch A (2016) The upcoming 3D-printing revolution in microfluidics. Lab Chip 16:1720

Cai J, Jiang J, Gao F, Jia G, Zhuang J, Tang G, Fan Y (2017) Rapid prototyping of cyclic olefin copolymer based microfluidic system with CO2 laser ablation. Microsyst Technol 1–7. doi:10.1007/s00542-017-3282-3

Chen L, Yin Z, Zou H et al (2017) A thermal bonding method based on O2 plasma and water treatment for fabrication of PET planar nanofluidic device. Microsyst Technol 23:1327

Deng W (2015) Fusion bonding recipes for glass-glass nanofluidic devices. Denman Undergraduate Research Forum

Díaz-González M, Baldi A, Chem A (2012) Fabrication of biofunctionalized microfluidic structures by low-temperature wax bonding. Anal Chem 84:7838–7844

Fan Y, Li H, Yi Y, Foulds IG (2013) PMMA to Polystyrene bonding for polymer based microfluidic systems. Microsyst Technol 20:59–64. doi:10.1007/s00542-013-1778-z

Ghobeity A, Crabtree HJ, Papini M, Spelt JK (2012) Characterisation and comparison of microfluidic chips formed using abrasive jet micromachining and wet etching. J Micromech Microeng 22:025014

Greener J, Li W, Ren J, Voicu D, Pakharenko V, Tang T, Kumacheva E (2010) Rapid, cost-efficient fabrication of microfluidic reactors in thermoplastic polymers by combining photolithography and hot embossing. Lab Chip 10:522–524

Leech PW, Wu N, Zhu Y (2011) Fabrication of microfluidic devices for droplet generation based on dry film resist. MRS Proceed. doi:10.1557/proc-1191-oo04-10

Lin T-Y et al (2017) 3D printed metal molds for hot embossing plastic microfluidic devices. Lab chip 17(2):241–247

Liu J, Shang J, Tang J, Huang QA (2011) Micromachining of Pyrex 7740 glass by silicon molding and vacuum anodic bonding. Microelectromech Syst J 20:909–915

Liu K et al (2017) PMMA microfluidic chip fabrication using laser ablation and low temperature bonding with OCA film and LOCA. Microsyst Technol 23(6):1937–1942

Pan YJ, Yang RJ (2006) A glass microfluidic chip adhesive bonding method at room temperature. J Micromech Microeng 16:2666–2672

Queste S, Salut R, Clatot S, Rauch JY, Khan Malek CG (2010) Manufacture of microfluidic glass chips by deep plasma etching, femtosecond laser ablation, and anodic bonding. Microsyst Technol 16:1485–1493

Samel, Chowdhury MK, Stemme (2007) The fabrication of microfluidic structures by means of full-wafer adhesive bonding using a poly(dimethylsiloxane) catalyst. J Micromech Microeng 17:1710

Stephan K, Pittet P, Renaud L, Kleimann P, Morin P, Ouaini N, Ferrigno R (2007) Fast prototyping using a dry film photoresist: microfabrication of soft-lithography masters for microfluidic structures. J Micromech Microeng 17:N69–N74. doi:10.1088/0960-1317/17/10/n01

Sticker D, Rothbauer M, Lechner S, Hehenberger MT, Ertl P (2015) Multi-layered, membrane-integrated microfluidics based on replica molding of a thiol-ene epoxy thermoset for organ-on-a-chip applications. Lab Chip 15:4542

Swierkowski SP, Davidson JC, Balch JW (2000) Vacuum fusion bonding of glass plates. US Patent 6,131,410, 17 Oct 2000

Toossi A et al (2015) Bonding PMMA microfluidics using commercial microwave ovens. J Micromech Microeng 25(8):085008

Tsao CW, Hromada L, Liu J, Kumar P, Devoe DL (2007) Low temperature bonding of PMMA and COC microfluidic substrates using UV/ozone surface treatment. Lab Chip 7:499

Wan AM, Sadri A, Young EW (2015) Liquid phase solvent bonding of plastic microfluidic devices assisted by retention grooves. Lab Chip 15:3785

Yazdi AA, Popma A, Wong W, Nguyen T, Pan Y, Xu J (2016) 3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications. Microfluid Nanofluid 20:50

Yu L, Shi ZZ (2015) Microfluidic paper-based analytical devices fabricated by low-cost photolithography and embossing of Parafilm®. Lab Chip 15:1642–1645

Yu H, Chong ZZ, Tor SB, Liu E, Loh NH (2015) Low temperature and deformation-free bonding of PMMA microfluidic devices with stable hydrophilicity via oxygen plasma treatment and PVA coating. RSC Adv 5:8377–8388

Yu S, Ng SP, Wang Z, Tham CL, Soh YC (2016) Thermal bonding of thermoplastic elastomer film to PMMA for microfluidic applications. Surf Coat Technol. doi:10.1016/j.surfcoat.2016.11.102

Zhang M, Wu J, Wang L, Xiao K, Wen W (2010) A simple method for fabricating multi-layer PDMS structures for 3D microfluidic chips. Lab Chip 10:1199–1203

Zhang L, Wang W, Ju XJ, Xie R, Liu Z, Chu LY (2014) Fabrication of glass-based microfluidic devices with dry film photoresists as pattern transfer masks for wet etching. RSC Adv 5:5638–5646

Zhao S, Cong H, Pan T (2009) Direct projection on dry-film photoresist (DP(2)): do-it-yourself three-dimensional polymer microfluidics. Lab Chip 9:1128–1132. doi:10.1039/b817925e

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (ZY1613, buctrc201609).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, Y., Liu, S. & Zhang, Y. Direct bonding of polymer/glass-based microfluidic chips with dry film photoresist. Microsyst Technol 24, 1659–1665 (2018). https://doi.org/10.1007/s00542-017-3541-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3541-3