Abstract

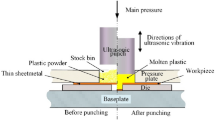

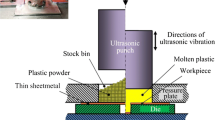

In this work, a micro punching equipment was designed and assembled for punching components with micro hole array. Micro hole array in 800 μm scale was punched successfully on blanked parts using this equipment. Punch experiments under different punch conditions were conducted to explore the effect laws of cavity depth, punch force and punch speed on punching process and quality of punched holes. To improve the process performance of the developed equipment, an ultrasonic vibration module was designed and assembled to the existing system based on its function of softening materials, the equipment’s process parameter scope such as cavity depth was optimized then. The results in this work proved the practicability of the developed micro punching equipment for punching components with micro hole array, the influence mechanism of punching conditions on punching process, and the optimization function of ultrasonic vibration on micro punching process, which could be useful in improving machining efficiency and cost of punch fabrication.

Similar content being viewed by others

References

Altan T, Oh SI, Gegel G (1983) Metal forming fundamentals and applications. American Society for Metal, Metals Park

Cheong MS, Cho DW, Ehmann KF (1999) Identification and control for micro-drilling productivity enhancement. Int J Mach Tools Manuf 39:1539–1561

Chern GL, Wang SD (2007) Punching of noncircular micro-holes and development of micro-forming. Precis Eng 31:210–217

Chern GL, Wu YJE, Liu SF (2006) Development of a micro-punching machine and study on the influence of vibration machining in micro-EDM. J Mater Process Technol 180:102–109

Geigerl M, Kleine M, Eckstein R, Tieslerl N, Engel U (2001) Microforming. CIRP Ann Manuf Technol 50:445–459

Joo BY, Oh SI, Jeon BH (2001) Development of micro punching system. CIRP Ann Manuf Technol 50:191–194

Joo B, Rhim S, Oh SI (2005) Micro-hole fabrication by mechanical punching process. J Mater Process Technol 170:593–601

Kasaai MR, Lagacé S, Boudreau D et al (2001) Creation of micro-holes on glass surface by femtosecond laser through the ejection of molten material. J Non Cryst Solids 292:202–209

Kim DW, Lee YS, Park MS, Chu CN (2009) Tool life improvement by peck drilling and thrust force monitoring during deep-micro-hole drilling of steel. Int J Mach Tools Manuf 49:246–255

Kolleck R, Vollmer R, Veit R (2011) Investigation of a combined micro-forming and punching process for the realization of tight geometrical tolerances of conically formed hole patterns. CIRP Ann Manuf Technol 60:331–334

Liu H, Yan B, Huang F, Qiu K (2005) A study on the characterization of high nickel alloy micro-holes using micro-EDM and their applications. J Mater Process Technol 169:418–426

Masuzawa T, Tsukamoto J, Fujino M (1989) Drilling of deep microholes by EDM. CIRP Ann Manuf Technol 38:195–198

Mochimaru Y, Ota M, Yamaguchi K (2012) Micro hole processing using electro-chemical discharge machining. J Adv Mech Des Syst 6:949–957

Sen M, Shan HS (2004) A review of electrochemical macro- to micro-hole drilling processes. Int J Mach Tools Manuf 45:137–152

Tönshoff HK, Hesse D, Mommsen J (1993) Micromachining using excimer lasers. CIRP Ann Manuf Technol 42:247–251

Wen T, Wei L, Chen X, Pei C (2011) Effects of ultrasonic vibration on plastic deformation of AZ31 during the tensile process. Int J Miner Metall Mater 18:70–76

Xu J, Guo B, Shan D, Wang Z, Li M, Fei X (2014) Micro-punching process of stainless steel foil with micro-die fabricated by micro-EDM. Microsyst Technol 20:83–89

Yang CT, Ho SS, Yan BH (2001) Micro hole machining of borosilicate glass through electrochemical discharge machining (ECDM). Key Eng Mater 196:149–166

Yi SM, Joo BY, Park SM, Chong CN, Oh SI (2006) Mechanical punching of 15 μm size hole. Microsyst Technol 12:877–882

Zhu D, Qu NS, Li HS, Zeng YB, Li DL, Qian SQ (2009) Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann Manuf Technol 58:177–180

Acknowledgments

This work was supported by National Science and Technology Major Projects of China (Grant No. 2013ZX04001-091-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Sun, J., Zhou, S., Yang, X. et al. Polyurethane-rubber punching process for micro-hole arrays. Microsyst Technol 23, 2943–2950 (2017). https://doi.org/10.1007/s00542-016-3089-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-3089-7