Abstract

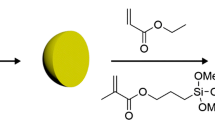

Hollow gel microparticles with shells composed of functional polymer gels are expected to be useful in the production of food additives or anti-reflective films for liquid crystal displays. However, few studies have addressed methods for the simple and efficient production of hollow gel microparticles. Hollow gel microparticles would be expected to find widespread applications if they could be fabricated more easily. In this study, we succeeded in fabricating hollow gel microparticles simply by atomizing a gas-supersaturated aqueous sodium alginate solution into aqueous calcium chloride solution. The gas-supersaturated aqueous sodium alginate solution was prepared by gas pressurization; following a rapid pressure decrease, the excess dissolved gas appeared as microbubbles in the atomized droplets. When the atomized droplets, with encapsulated microbubbles, came into contact with the aqueous calcium chloride solution, the droplets were converted to a gel by ionic crosslinking between sodium alginate and calcium ions, and any remaining bubbles were trapped inside the droplets. With this method, we can fabricate calcium alginate hollow gel microparticles of less than 100 μm with multi-voids. Furthermore, these hollow structures can be controlled by changing the compression pressure, which changes the amount of dissolved gas in the liquid.

Similar content being viewed by others

References and citations

Ahn JS, Troy R, Hendricks TR, Lee I (2007) Control of specular and diffuse reflection of light using particle self-assembly at the polymer and metal interface. Adv Funct Mater 17:3619–3625

Bertling J, Blömer J, Kümmel R (2004) Hollow microspheres. Chem Eng Technol 27:829–837

Daiguji H, Makuta T, Kinoshita H, Oyabu T, Takemura F (2007) Fabrication of hollow melamine-formaldehyde microcapsules from microbubble template. J Phys Chem B 111:8879–8884

Koichi T, Ai H, Takanori N, Satoko F, Daisuke K (2011) Development of microbubble aerator for waste water treatment using aerobic activatedsludge. Chem Eng Sci 66:3172–3179

Makuta T, Takada S, Daiguji H, Takemura F (2009) Simple fabrication of hollow poly-lactic acid microspheres using uniform microbubbles as templates. Mater Lett 63:703–705

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eguro, T., Makuta, T. The fabrication technique for hollow gel microparticles using microbubble templates. Microsyst Technol 23, 1171–1175 (2017). https://doi.org/10.1007/s00542-016-3046-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-3046-5