Abstract

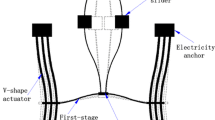

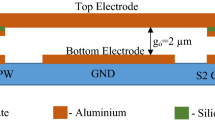

The design, fabrication and test of electro-thermal safety-and-arming (SA) device are investigated. The device contains movable structure (comprised by 4 electro-thermal actuators) and propellant cavity. In order to enhance the reliability of SA device, interlock mechanisms are introduced. With proper driven voltages, the device can commute from safe mode to arming mode in 16 ms and generate sufficient space for propellant explosion. The maximum displacement of the device is 402.18 μm with 97.92 mJ (6.12 W during 16 ms) power consumption. silicon-on-insulator wafer and inductively-coupled-plasma are introduced in fabricate process and the chip size is minimized into 8 mm × 8 mm × 0.5 mm successfully.

Similar content being viewed by others

References

Dong Y, Amir K, Raafat M (2003) Modeling of two-hot-arm horizontal thermal actuator. J Micromech Microeng 13:312–322

Eniko TE, Shantanu SK, Kalin VL (2005) Analytical model for analysis and design of V-shaped thermal microactuators. J Microelectromech Syst 14(4):788–798

Fan L, Last H, Wood R et al (1998) SLIGA based underwater weapon safety and arming system. Microsyst Technol 4:168–171

Hélène P, Carole R, Marjorie S et al (2010) Integration of a MEMS based safe arm and fire device. Sens Actuators A 159:157–167

James LZ, Donald RS, Charles R (2008) Reliability testing and analysis of safing and arming devices for army fuzes. In: Proceedings of SPIE 6884:0C1–0C12

Jay JK, Qu HW (2011) Design and fabrication of electro-thermally activated micro gripper with large tip opening and holding force. In: IEEE 2011 conference

Lai YJ, Bordatchev EV, Nikumb SK et al (2006) Performance characterization of in-plane electro-thermally driven linear microactuators. J Intell Mater Syst Struct 17:919–929

Li XY, Zhao YL, Hu TJ et al (2015) Design of a large displacement thermal actuator with a cascaded V-beam amplification for MEMS safety-and-arming devices. Microsyst Technol. doi:10.1007/s00542-015-2447-1

Steven SM (2006) Microelectromechanical system (MEMS) interrupter for safe and arm devices. Dissertation, Air force institute of technology

Ostrow SA II, Lake RA, Lombardi JP III et al (2012) Fabrication process comparison and dynamics evaluation of electrothermal actuators for a prototype MEMS safe and arming devices. Exp Mech 52:1229–1238

Radu SC, Mircea CD, Marius P et al (2014) Analytical and numerical study on the maximum force developed by a V-beam thermal actuator. Proc Technol 12:359–363

Robert AL, LaVern AS, Ronald AC (2010) Electrothermal actuators for integrated MEMS safe and arming devices. In: Proceedings of the SEM annual conference, June 7–10, Indianapolis

Robinson CH, Wood RH, Hoang TQ (2005) Miniature MEMS-based electro-mechanical safety and arming device. US Patent 6964231 B1, 15 Nov 2005

Walter HM, Gabriel HS, David RH (2006) Method for utilizing a MEMS safe arm device for microdetonation. US Patent 7007606 B1, 7 March 2006

Yang YS, Lin YH, Hu YC et al (2009) A large-displacement thermal actuator designed for MEMS pitch-tunable grating. J Micromech Microeng 19:015001

Zhang YX, Huang QA, Li RG et al (2006) Macro-modeling for polysilicon cascaded bent beam electrothermal microactuators. Sens Actuators A 128:165–175

Acknowledgments

The work was supported by Changjiang Scholars and Innovative Research Team (No. IRT_14R45) and The National Science Fund for Distinguished Young Scholars (No. 51325503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, T., Zhao, Y., Li, X. et al. Integration design of MEMS electro-thermal safety-and-arming devices. Microsyst Technol 23, 953–958 (2017). https://doi.org/10.1007/s00542-016-2901-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2901-8