Abstract

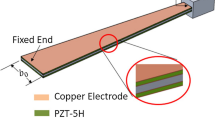

In this contribution, we discuss a novel design concept of a high-performance wideband MEMS vibration energy harvester (EH), named four-leaf clover (FLC EH-MEMS) after its circular shape featuring four petal-like mass-spring systems. The goal is to enable multiple resonant modes in the typical range of vibrations scattered in the environment (i.e., up to 4–5 kHz). This boosts the FLC conversion capability from mechanical into electrical energy exploiting the piezoelectric effect, thus overcoming the common limitation of cantilever-like EHs that exhibit good performance only in a very narrow band of vibration (i.e., fundamental resonant mode). The FLC concept is first discussed framing it into the current state of the art, highlighting its strengths. Then, after a brief theoretical introduction on mechanical resonators, the FLC EH-MEMS device is described in details. Finite Element Method (FEM) analyses are conducted in the ANSYS Workbench™ framework. A suitable 3D model is built up to perform modal simulations, aimed to identify mechanical resonant modes, as well as harmonic analyses, devoted to study the mechanical and electrical behaviour of the FLC EH-MEMS (coupled field analysis). The work reports on experimental activities, as well. Physical samples of the FLC EH-MEMS device are fabricated within a technology platform that combines surface and bulk micromachining. Thereafter, specimens are tested both with a laser doppler vibrometer measurement setup as well as with a dedicated shaker-based setup, and the results are compared with simulations for validation purposes. In conclusion, the FLC EH-MEMS exhibits a large number of resonant modes scattered in the tested range of vibrations (up to 15 kHz) already starting from frequencies as low as 200 Hz, and expected levels of converted power better than 10 µW.

Similar content being viewed by others

References

Ababneh A, Schmid U, Hernando J, Sánchez-Rojas JL, Seidel H (2010) The influence of sputter deposition parameters on piezoelectric and mechanical properties of AlN thin films. Mater Sci Eng B 172:253–258

Akiyama M, Kano K, Teshigahara A (2009) Influence of growth temperature and scandium concentration on piezoelectric response of scandium aluminum nitride alloy thin films. Appl Phys Lett 95:1–3

ANSYS Parametric Design Language (APDL). http://www.mece.ualberta.ca/tutorials/ansys/AT/APDL/APDL.html. Accessed 15 May 2015

Beeby S, White N (eds) (2010) Energy harvesting for autonomous systems. Artech House, London

Beigelbeck R, Schneider M, Schalko J, Bittner A, Schmid U (2014) A two-step load-deflection procedure applicable to extract the Young’s modulus and the residual tensile stress of circularly shaped thin-film diaphragms. J Appl Phys 116:1–13

Brennen RA, Pisano AP, Tang WC (1990) Multiple mode micromechanical resonators. In: Proceedings of IEEE MEMS, pp 9–14

Casset F, Durand C, Dedieu S, Carpentier JF, Gonchond JP, Ancey P, Robert P (2009) 3D multi-frequency MEMS electromechanical resonator design. In: Proceedings of EuroSimE, pp 1–5

Chamanian S, Bahrami M, Zangabad RP, Khodaei M, Zarbakhsh P (2012) Wideband capacitive energy harvester based on mechanical frequency-up conversion. In: Proceedings of IEEE SAS, pp 1–4

Chandrahalim H, Bhave SA (2008) Digitally-tunable mems filter using mechanically-coupled resonator array. In: Proceedings of IEEE MEMS, pp 1020–1023

Chidambaram N, Mazzalai A, Muralt P (2012) Comparison of lead zirconate titanate (PZT) thin films for MEMS energy harvester with interdigitated and parallel plate electrodes. In: Proceedings of ISAF/ECAPD/PFM, pp 1–4

Chidambaram N, Mazzalai A, Balma D, Muralt P (2013) Comparison of lead zirconate titanate thin films for microelectromechanical energy harvester with interdigitated and parallel plate electrodes. IEEE Trans Ultrason Ferroelectr Freq Control 60:1564–1571

Collado A, Georgiadis A (2013) Conformal hybrid solar and electromagnetic (EM) energy harvesting rectenna. IEEE Trans Circuits Syst 60:2225–2234

Cugat O, Delamare J, Reyne G (2003) Magnetic micro-actuators and systems (MAGMAS). IEEE Trans Magn 39:3607–3612

Dargie W, Poellabauer C (2010) Fundamentals of wireless sensor networks: theory and practice. John Wiley and Sons, Hoboken

Dini M, Romani A, Filippi M, Bottarel V, Ricotti G, Tartagni M (2015) A nano-current power management ic for multiple heterogeneous energy harvesting sources. IEEE Trans Power Electron. doi:10.1109/TPEL.2014.2379622

Erturk A, Inman DJ (2011) Piezoelectric energy harvesting. John Wiley and Sons, Hoboken

Ferrari M, Ferrari V, Guizzetti M, Marioli D, Taroni A (2008) Piezoelectric multifrequency energy converter for power harvesting in autonomous microsystems. Sens Actuators A: Phys 142:329–335 (Elsevier)

Fu JL, Nakano Y, Sorenson LD, Ayazi F (2012) Multi-axis AlN-on-silicon vibration energy harvester with integrated frequency-upconverting transducers. In: Proceedings of IEEE MEMS, pp 1269–1272

Galchev T, Aktakka EE, Najafi K (2012) A piezoelectric parametric frequency increased generator for harvesting low-frequency vibrations. IEEE JMEMS 21:1311–1320

Goldschmidtboeing F, Wischke M, Eichhorn C, Woias P (2009) Nonlinear effects in piezoelectric vibration harvesters with high coupling factors. In: Proceedings of PowerMEMS, pp 364–367

Hagiwara K, Goto M, Iguchi Y, Tajima T, Yasuno Y, Kodama H, Kidokoro K, Suzuki Y (2012) Electret charging method based on soft X-ray photoionization for MEMS transducers. IEEE Trans Dielectr Electr Insul 19:1291–1298

Hajati A, Bathurst SP, Lee HJ, Kim SG (2011) Design and fabrication of a nonlinear resonator for ultra wide-bandwidth energy harvesting applications. In: Proceedings of IEEE MEMS, pp 1301–1304

Halvorsen E (2012) Fundamental issues in nonlinear wide-band vibration energy harvesting. APS Phys Rev E 87:1–6

Iannacci J, Sordo G (2016) Up-scaled macro-device implementation of a MEMS wideband vibration piezoelectric energy harvester design concept. Springer Microsystem Technologies XX:1–13. doi:10.1007/s00542-015-2794-y

Iannacci J, Serra E, Di Criscienzo R, Sordo G, Gottardi M, Borrielli A, Bonaldi M, Kuenzig T, Schrag G, Pandraud G, Sarro PM (2014) Multi-modal vibration based MEMS energy harvesters for ultra-low power wireless functional nodes. Springer Microsyst Technol 20:627–640

IXYS Solar Cell Products (2015) http://www.ixysic.com/Products/SolarCell.htm. Accessed 14 May 2015

Janphuang P, Lockhart R, Briand D, de Rooij NF (2014) On the optimization and performances of a compact piezoelectric impact MEMS energy harvester. In: Proceedings of IEEE MEMS, pp 429–432

Kamierski TJ, Beeby S (2010) Energy harvesting systems: principles, modeling and applications. Springer, Berlin

Kim I-H, Jung H-J, Lee BM, Jang S-J (2011) Broadband energy-harvesting using a two degree-of-freedom vibrating body. Appl Phys Lett 98:1–3

Kutiš V, Dzuba J, Paulech J, Murín J, Lalinský T (2012) MEMS piezoelectric pressure sensor-modelling and simulation. Procedia Eng 48:338–345. doi:10.1016/j.proeng.2012.09.523 (Elsevier)

Kymissis J, Kendall C, Paradiso J, Gershenfeld N (1998) Parasitic power harvesting in shoes. In: Proceedings of ISWC, pp 132–139

Lee BS, Wu WJ, Shih W-P, Vasic D, Costa F (2007) P2E−3 power harvesting using piezoelectric MEMS generator with interdigital electrodes. In: Proceedings of IEEE Ultrasonics Symposium, pp 1598–1601

Liu SW, Lye SW, Miao JM (2012) Sandwich structured electrostatic/electrets parallel-plate power generator for low acceleration and low frequency vibration energy harvesting. In: Proceedings of IEEE MEMS, pp 1277–1280

Mayrhofer PM, Euchner H, Bittner A, Schmid U (2015) Circular test structure for the determination of piezoelectric constants of ScxAl1−xN thin films applying laser doppler vibrometry and FEM simulations. Sens Actuators A: Phys 222:301–308 (Elsevier)

Miki S, Fujita T, Kotoge T, Jiang YG, Uehara M, Kanda K, Higuchi K, Maenaka K (2012) Electromagnetic energy harvester by using buried NdFeB. In: Proceedings of IEEE MEMS, pp 1221–1224

Ou Q, Chen X, Gutschmidt S, Wood A, Leigh N (2010) A two-mass cantilever beam model for vibration energy harvesting applications. In: Proceedings of IEEE Conference on Automation Science and Engineering (CASE), pp 301–306

Percy S, Knight C, McGarry S, Post A, Moore T, Cavanagh K (2014) Thermal energy harvesting for application at MEMS scale. Springer, Berlin

Popovic Z, Falkenstein EA, Costinett D, Zane R (2013) Low-power far-field wireless powering for wireless sensors. Proceedings of IEEE 101:1397–1407

Prabha RD, Rincon-Mora GA, Kim S (2011) Harvesting circuits for miniaturized photovoltaic cells. In: IEEE ISCAS International Symposium, pp 309–312

Qi S, Shuttleworth R, Oyadiji SO, Wright J (2010) Design of a multiresonant beam for broadband piezoelectric energy harvesting. IOP smart materials and structures 19:1–10

Romani A, Paganelli RP, Sangiorgi E, Tartagni M (2013) Joint modeling of piezoelectric transducers and power conversion circuits for energy harvesting applications. IEEE Sens J 13:916–925

Roundy S, Wright PK, Rabaey JM (2004) Energy scavenging for wireless sensor networks: with special focus on vibrations. Kluwer Academic Publishers, Dordrecht

Sanchez-Rojas JL, Hernando J, Donoso A, Bellido JC, Manzaneque T, Ababneh A, Seidel H, Schmid U (2010) Modal optimization and filtering in piezoelectric microplate resonators. J Micromech Microeng 20:1–7

Schneider M, Bittner A, Patocka F, Stöger-Pollach M, Halwax E, Schmid U (2012) Impact of the surface-near silicon substrate properties on the microstructure of sputter-deposited AlN thin films. Appl Phys Lett 101:1–3

Schneider M, Bittner A, Schmid U (2014) Thickness dependence of Young’s modulus and residual stress of sputtered aluminum nitride thin films. Appl Phys Lett 105:1–4

Shahruz SM (2006) Design of mechanical band-pass filters for energy scavenging. J Sound Vib 292:987–998

Suzuki M, Matsushita N, Hirata T, Yoneya R, Onishi J, Wada T, Takahashi T, Nishida T, Yoshikawa Y, Aoyagi S (2011) Fabrication of highly dielectric nano-BaTiO3/epoxy-resin composite plate having trenches by mold casting and its application to capacitive energy harvesting. In:Proceedings of IEEE Transducers, pp 2642–2645

Tao K, Ding G, Wang P, Yang Z, Wang Y (2012) Fully integrated micro electromagnetic vibration energy harvesters with micro-patterning of bonded magnets. In: Proceedings of IEEE MEMS, pp 1237–1240

Todorov G, Valtchev S, Todorov T, Ivanov I, Klaassens B (2011) Tuning techniques for kinetic MEMS energy harvesters. In: Proceedings of IEEE INTELEC, pp 1–6

Uckelmann D, Harrison M, Michahelles F (eds) (2011) Architecting the internet of things. Springer, Berlin

Vasseur J-P, Dunkels A (2010) Interconnecting smart objects with IP: the next internet. Morgan Kaufmann Publishers, Burlington

Vullers RJM, Schaijk RV, Visser HJ, Penders J, Hoof CV (2010) Energy harvesting for autonomous wireless sensor networks. IEEE Solid-State Circuits Mag 2:29–38

Xue H, Hu Y, Wang Q-M (2008) Broadband piezoelectric energy harvesting devices using multiple bimorphs with different operating frequencies. IEEE Trans Ultrason Ferroelectr Freq Control 55:2104–2108

Zhu D (2011) Vibration energy harvesting: machinery vibration, human movement and flow induced vibration, in sustainable energy harvesting technologies—past present and future. InTech, Rijeka

Zhu M, Worthington E, Njuguna J (2009) Coupled piezoelectric-circuit FEA to study influence of a resistive load on power output of piezoelectric energy devices. Proc SPIE Smart Sens Actuators, MEMS IV 7326:1–12

Zorlu O, Topal ET, Külah H (2011) A vibration-based electromagnetic energy harvester using mechanical frequency up-conversion method. IEEE Sens J 11:481–488

Zukauskaite A, Wingqvist G, Palisaitis J, Jensen J, Persson Per OÅ, Matloub R, Muralt P, Kim Y, Birch J, Hultman L (2012) Microstructure and dielectric properties of piezoelectric magnetron sputtered w ScxAl1 xN thin films. J Appl Phys 111:1–7

Acknowledgments

The authors would like to thank Prof. Aldo Romani, Prof. Marco Tartagni, MSc. Michele Dini, BSc. Matteo FIlippi and the staff of the characterization lab with the Department of Electrical, Electronic, and Information Engineering “Guglielmo Marconi” (DEI) at University of Bologna (Italy), Campus of Cesena, for giving access and providing advice in using their experimental setup based on vibration test system by Tira GmbH and laser displacement sensors by Keyence Corporation, that was then implemented with similar equipment at FBK and exploited for the preliminary electrical characterization of the FLC EH-MEMS fabricated samples reported above.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Iannacci, J., Sordo, G., Serra, E. et al. The MEMS four-leaf clover wideband vibration energy harvesting device: design concept and experimental verification. Microsyst Technol 22, 1865–1881 (2016). https://doi.org/10.1007/s00542-016-2886-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2886-3