Abstract

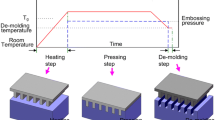

This study conducted technical research into gas-assisted light-cure transfer molding and transfer transformation. With the self-developed light-cure transfer molding system, we created the system devices through mechanical processing. Then, the soft micro-nanometer structure was combined with different gas pressures and experimental parameters to explore the formation of micro-structural components. Meanwhile, the gas pressure was increased to achieve transfer transformation and analysis. According to the experimental results, the duplicated formation would lead to complete formation with the increased gas pressure. Moreover, this study indicated that excessive gas pressure would transform the microstructure, and then change the height and shape of the micro-structural components after transfer molding. This study also analyzed the transformation to gain information regarding transfer molding and transformation under the conditions, and thus, obtain the array microstructure of various forms. It is predicted that this study can be regarded as an option for the fabrication of micro-systematic structural components.

Similar content being viewed by others

References

Fiederling R, Keim M, Reuscher G, Ossau W, Schmidt G, Waag A, Molenkamp LW (1999) Injection and detection of a spin-polarized current in a light-emitting diode. Nature 402(6763):787–790

Goral VN, Hsieh YC, Petzold ON, Faris RA, Yuen PK (2011) Hot embossing of plastic microfluidic devices using poly (dimethylsiloxane) molds. J Micromech Microeng 21(1):017002

Han JH, John DF (1997) Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J Plast Film Sheeting 13(4):287–298

Kung FC, Weng YJ (2008) Optimizations of the processing parameters of high-performance engineering plastic in injection molding. Polym-Plast Technol 47(11):1154–1161

Lee SW, Lee KS, Ahn J, Lee JJ, Kim MG, Shin YB (2011) Highly sensitive biosensing using arrays of plasmonic Au nanodisks realized by nanoimprint lithography. ACS Nano 5(2):897–904

Martyushev N, Semenkov IV (2014) The possibility of casting surface alloying by nanopowders. Adv Mater Res 880:272–275

Palermo G, Joris H, Devroey P, Van Steirteghem AC (1992) Pregnancies after intracytoplasmic injection of single spermatozoon into an oocyte. Lancet 340(8810):17–18

Powell BR, Rezhets V, Balogh MP, Waldo RA (2002) Microstructure and creep behavior in AE42 magnesium die-casting alloy. JOM 54(8):34–38

Söderström K, Escarré J, Cubero O, Haug FJ, Perregaux S, Ballif C (2011) UV-nano-imprint lithography technique for the replication of back reflectors for n-i-p thin film silicon solar cells. Prog Photovolt Res Appl 19(2):202–210

Trompoukis C, El Daif O, Depauw V, Gordon I, Poortmans J (2012) Photonic assisted light trapping integrated in ultrathin crystalline silicon solar cells by nanoimprint lithography. Appl Phys Lett 101(10):103901

Weng YJ (2015) UV-curable technique of magnetic roller soft mold and microstructure pattern replication. Int Polym Proc 30(1):63–69

Weng YJ, Chen RH (2015) The application of magnetic fluid bag micro-roll imprinting technology in optical anti-reflective and solar concentrator soft film replication. Optik 126(19):2080–2086

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weng, YJ., Chang, CL. & Hsiao, YH. Gas-assisted light-cure microstructure transfer molding and transfer transformation. Microsyst Technol 23, 1081–1090 (2017). https://doi.org/10.1007/s00542-016-2823-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2823-5