Abstract

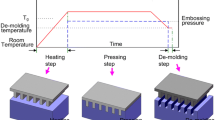

Thermal nanoimprinting of polyethylene terephthalate (PET) is another ideal method for fabrication of 2D (two dimensional) nanochannels with low cost and high replication precision. However, the demolding stage which influences the replication precision of the final PET nanochannels has not yet been studied. In this work, the effect of the demolding angle, demolding temperature and friction coefficient between the 2D silicon nano-mold and the PET substrate on the maximum local stress of the 2D PET nanochannels was investigated by finite element method. The results show that the maximum local stress appears at 0.8 s (the total demolding time is 1 s), which indicates that the damage of PET nanochannels could be more likely to occur at the end of the demolding stage. According to the simulation results, in order to separate the 2D silicon nano-mold and the PET substrate without nanochannels damage, the following processing parameters are suggested: demolding angle of 0°, demolding temperature of 55 °C and an anti-sticking treatment on the surface of the mold.

Similar content being viewed by others

References

Cecchini M, Signori F, Pingue P, Bronco S, Ciardelli F, Beltram F (2008) High-resolution poly(ethylene terephthalate) (PET) hot embossing at low temperature: thermal, mechanical, and optical analysis of nanopatterned films. Langmuir 24(21):12581–12586

Chantiwas R, Hupert ML, Pullagurla SR, Balamurugan S, Tamarit-Lopez J, Park S, Datta P, Goettert J, Cho Y-K, Soper SA (2010) Simple replication methods for producing nanoslits in thermoplastics and the transport dynamics of double-stranded DNA through these slits. Lab Chip 10(23):3255–3264

Chantiwas R, Park S, Soper SA, Kim BC, Takayama S, Sunkara V, Hwang H, Cho YK (2011) Flexible fabrication and applications of polymer nanochannels and nanoslits. Chem Soc Rev 40(7):3677–3702

Chun D, Kim SH, Song H, Kwak S, Kim Y, Seok H, Lee S-M, Lee JH (2013) Fast myoglobin detection using nanofluidic electrokinetic trapping technique. Appl Phys Express 6(1):017001

Freedman KJ, Haq SR, Edel JB, Jemth P, Kim MJ (2013) Single molecule unfolding and stretching of protein domains inside a solid-state nanopore by electric field. Sci Rep 3:1638

Gillespie D, Pennathur S (2013) Separation of Ions in nanofluidic channels with combined pressure-driven and electro-osmotic flow. Anal Chem 85(5):2991–2998

Guo LJ (2004) Recent progress in nanoimprint technology and its applications. J Phys D Appl Phys 37(11):R123–R141

Kim NW, Kim KW, Sin H-C (2008) Finite element analysis of low temperature thermal nanoimprint lithography using a viscoelastic model. Microelectron Eng 85(9):1858–1865

Lan S, Lee HJ, Lee SH, Ni J, Lai X, Lee HW, Song JH, Lee MG (2009) Experimental and numerical study on the viscoelastic property of polycarbonate near glass transition temperature for micro thermal imprint process. Mater Des 30(9):3879–3884

Li JM, Liu C, Qiao HC, Zhu LY, Chen G, Dai XD (2008) Hot embossing/bonding of a poly(ethylene terephthalate) (PET) microfluidic chip. J Micromech Microeng 18(1):015008

Pedersen JN, Marie R, Bauer DLV, Rasmussen KH, Yusuf M, Volpi EV, Kristensen A, Mir KU, Flyvbjerg H (2013) Fully Streched single DNA molecules in a nanofluidic chip show large-scale structural variation. Biophys J 104(2):175A

Peng L, Shuang P, Hao J, Qiangfei X (2013) Mold cleaning with polydimethylsiloxane for nanoimprint lithography. Nanotechnology 24(32):325301

Rao J, Zou H, Syms RRA, Cheng E, Liu C (2011) Fabrication of 2D silicon nano-mold based on sidewall transfer. Micro Nano Lett 6(1):29–33

Sakamoto J, Fujikawa N, Nishikura N, Kawata H, Yasuda M, Hirai Y (2011) High aspect ratio fine pattern transfer using a novel mold by nanoimprint lithography. J Vac Sci Technol B 29(6):06FC15

Sang J, Du H, Wang W, Chu M, Wang Y, Li H, Zhang HA, Wu W, Li Z (2013) Protein sensing by nanofluidic crystal and its signal enhancement. Biomicrofluidics 7(2):024112

Sparreboom W, van den Berg A, Eijkel JCT (2009) Principles and applications of nanofluidic transport. Nat Nanotechnol 4(11):713–720

Tsukahara T (2010) Nanofluidic-based separation system of radionuclide ions by controlling electrostatic forces. Bull Res Lab Nucl React 34:51

van Kan JA, Zhang C, Malar PP, van der Maarel JRC (2012) High throughput fabrication of disposable nanofluidic lab-on-chip devices for single molecule studies. Biomicrofluidics 6(3):036502

Wu J, Chantiwas R, Amirsadeghi A, Soper SA, Park S (2011) Complete plastic nanofluidic devices for DNA analysis via direct imprinting with polymer stamps. Lab Chip 11(17):2984–2989

Yin Z, Cheng E, Zou H, Chen L, Xu S (2014a) Fabrication of two dimensional polyethylene terephthalate nanofluidic chip using hot embossing and thermal bonding technique. Biomicrofluidics 8(6):066503

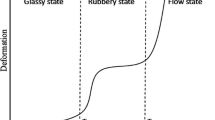

Yin Z, Cheng E, Zou H, Jurčíček P (2014b) Analysis of polymer viscoelastic properties based on compressive creep tests during hot embossing for two-dimensional polyethylene terephthalate nanochannels. Polym Eng Sci 54(10):2398–2406

Zaroulis JS, Boyce MC (1997) Temperature, strain rate, and strain state dependence of the evolution in mechanical behaviour and structure of poly(ethylene terephthalate) with finite strain deformation. Polymer 38(6):1303–1315

Zhou K, Li L, Tan Z, Zlotnick A, Jacobson SC (2011) Characterization of hepatitis B virus capsids by resistive-pulse sensing. J Am Chem Soc 133(6):1618–1621

Acknowledgments

This project is supported by National Natural Science Foundation of China (Nos. 91023046, 51075059) and Specialized Research Fund for the Doctoral Program of Higher Education of China (SRFDP) (No. 20120041110034).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, Z., Sun, L. & Zou, H. Numerical analysis on PET demolding stage in thermal nanoimprinting lithography. Microsyst Technol 23, 899–905 (2017). https://doi.org/10.1007/s00542-015-2761-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2761-7