Abstract

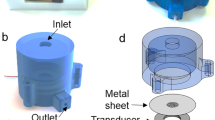

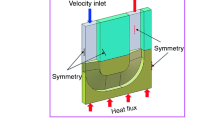

Nozzles with circular cross-section and a diameter varying in axial direction have been fabricated in a microfluidic channel from polyvinylidene fluoride as chemically resistive thermoplastic polymer. Smallest diameter and length of the nozzle are approximately 150 µm and 3.4 mm, respectively. The nozzle and the entire channel system have been fabricated from two halves generated by ultrasonic hot embossing and bonded to each other by ultrasonic welding. Alignment during ultrasonic welding was assisted by a fit of energy directors and an accuracy of 35 and 10 µm in normal and lateral direction, respectively, was obtained. Thermoplastic molding of the two halves of the channel structures was performed by ultrasonic hot embossing with a cycle time of a few seconds. The development was significantly accelerated by milling the tools directly into aluminum plates. This way, new designs were realized within a day. The micro nozzles have been proven generating liquid/liquid dispersions of different flow patterns as a function of flow velocity and Capillary number.

Similar content being viewed by others

References

Burns JR, Ramshaw C (2001) The intensification of rapid reactions in multiphase systems using slug flow in capillaries. Lab Chip 1:10–15

Christopher GF, Anna SL (2007) Microfluidic methods for generating continuous droplet streams. J Phys D Appl Phys 40:R319–R336

de Menech M, Garstecki P, Jousse F, Stone HA (2008) Transition from squeezing to dripping in a microfluidic T-shaped junction. J Fluid Mech 595:141–161

Forrester SE, Rielly CD (1998) Bubble formation from cylindrical, flat and concave sections exposed to a strong liquid cross-flow. Chem Eng Sci 53:1517–1527

Fu T, Ma Y, Funfschilling D, Zhu C, Li HZ (2010) Squeezing-to-dripping transition for bubble formation in a microfluidic T-junction. Chem Eng Sci 65:3739–3748

Garstecki P (2010) Formation of droplets and bubbles in microfluidic systems. microfluidics based microsystems. Springer, Dordrecht

Gu H, Duits MHG, Mugele F (2011) Droplets formation and merging in two-phase flow microfluidics. Int J Mol Sci 12:2572–2597

Gupta A, Kumar R (2010) Effect of geometry on droplet formation in the squeezing regime in a microfluidic T-junction. Microfluid Nanofluid 8:799–812

Harsch S, Ehrfeld W, Maner A (1988) Untersuchungen zur Herstellung von Mikrostrukturen großer Strukturhöhe durch Galvanoformung in Nickelsulfamatelektrolyten. KfK-Bericht 4455, Kernforschungszentrum Karlsruhe, ISSN 0303-4003

Heckele M, Schomburg WK (2004) Review on micro molding of thermoplastic polymers. J Micromech Microeng 14:R1–R14. doi:10.1088/0960-1317/14/3/R01

Holvey C, Macchi A, Kockmann N, Roberge DM (2011) Pressure drop and mixing in single phase microreactors: simplified designs of micromixers. Chem Eng Proc 50:1069–1075

Kashid MN, Agar DW (2007) Hydrodynamics of liquid–liquid slug flow capillary microreactor: flow regimes, slug size and pressure drop. Chem Eng J 131:1–13

Khuntontong P, Blaser T, Schomburg WK (2008) Ultrasonic micro hot embossing of thermoplastic polymers. In: Proceedings of 24th Annual Meeting of the Polymer Processing Society, PPS24, Salerno, Italy, June 15–19. p 364

Kockmann N (2006) Micro process engineering. Wiley-VCH, Weinheim

Kockmann N (2008) Pressure loss and transport rates in microstructured devices with chemical reactions. Chem Eng echn 31:1188–1195

Kockmann N, Gottsponer M (2010) Heat transfer limitations of gas-liquid exothermic reactions in micro-channels. In: Proceedings of ASME-ICNMM2010. 30389, Montreal

Kockmann N, Roberge DM (2011) Scale-up concept for modular microstructured reactors based on mixing, heat transfer, and reactor safety. Chem Eng Pro 50:1017–1026

Kulkarni AA, Joshi JB (2005) Bubble Formation and Bubble Rise Velocity in Gas-Liquid Systems: a Review. Ind Eng Chem Res 44:5873–5931

Liao S, Gerhardy C, Sackmann J, Schomburg WK (2014) Tools for ultrasonic hot em-boss-ing. Microsyst Technol. doi:10.1007/s00542-014-2232-6

Liepe F, Meusel W, Möckel H, Platzer B, Weissgärber H (1988) Stoffvereinigen in fluiden Phasen. Verfahrens-technische Berechnungsmethoden. Wiley-VCH, Weinheim

Lin C-H, Chen R (2006) Ultrasonic nanoimprint lithography: a new approach to nanopatterning. J Micro/Nanolith MEMS MOEMS 5:1. doi:10.1117/1.2172992

Liu S-J, Dung Y-T (2005) Hot embossing precise structure onto plastic plates by ultrasonic vibration. Polym Eng Sci 45:915. doi:10.1002/pen.20357

Liu H, Zhang Y (2011) Droplet formation in microfluidic cross-junctions. Phys Fluids 23:082101–1–082101-12. doi:10.1063/1.3615643

Matsuyama K, Mine K, Kubo H, Aoki N, Mae K (2010) Optimization methodology of operation of orifice-shaped micromixer based on micro-jet concept. Chem Eng Sci 65:5912–5920

Mekaru H, Nakamura O, Maruyama O, Maeda R, Hattori T (2006) Development of precision transfer technology of atmospheric hot embossing by ultrasonic vibration. Microsyst Technol 13:385–391. doi:10.1007/s00542-006-0203-2

Mekaru H, Goto H, Takahashi M (2007) Development of ultrasonic micro hot embossing technology. Microelectron Eng 84:1282–1287. doi:10.1016/j.mee.2007.01.235

Memering B, Gerhardy C, Schomburg WK (2014) Roll-to-roll-production of micro structures in polymer foils by ultrasonic hot embossing. Publication “Microsystems Technology in Germany 2014”, trias consult, ISSN 2191-7183, pp 40–41, http://www.microsystems-technology-in-germany.de/MST%202014.pdf. Accessed 27 Oct 2015

Okubo Y, Maki T, Aoki N, Khoo TH, Ohmukai Y, Mae K (2008) Liquid-liquid extraction for efficient synthesis and separation by utilizing micro spaces. Chem Eng Sci 63:4070–4077

Park JM, Kim NH, Lee B-K, Lee K-H, Kwon TH (2008) Nickel stamp fabrication and hot embossing for mass-production of micro/nano combined structures using anodic aluminum oxide. Microsyst Technol 14:1689–1694. doi:10.1007/s00542-007-0504-0

Parmar R, Majumder SK (2013) Microbubble generation and microbubble-aided transport process intensification—A state-of-the-art report. Chem Eng Proc 64:79–97

Potente H (2004) Fügen von Kunststoffen—Grundlagen, Verfahren, Anwendung. Carl Hanser, München

Sackmann J, Burlage K, Gerhardy C, Memering B, Liao S, Schomburg WK (2015) Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 56:189–200. doi:10.1016/j.ultras.2014.08.007

Schubert H (2003) Handbuch der Mechanischen Verfahrenstechnik. Wiley-VCH, Weinheim

Seemann R, Brinkmann M, Pfohl T, Herminghaus S (2012) Droplet based microfluidics. Rep Prog Phys 75:1–41

Shao N, Gavriilidis A, Angeli P (2009) Flow regimes for adiabatic gas-liquid flow in microchannels. Chem Eng Sci 64:2749–2761

Song H, Chen DL, Ismagilov RF (2006) Reactions in droplets in microfluidic channels. Angew Chem Int Ed 45:7336–7356

Tollkoetter A, Kockmann N (2014) A modular microfluidic system for high flow rate re-dispersion of gas–liquid. In: Proceedings of ASME-ICNMM2014-22048, Chicago, Illinois

Tollkoetter A, Schirmbeck F, Wesholowski J, Kockmann N (2015) High flow rate micro orifice dispersion of gas–liquid flow. In: Proceedings of ASME-ICNMM2015-48221, San Francisco, California

Tollkoetter A, Sackmann J, Baldhoff T, Schomburg WK, Kockmann N (2015) Modulares Mikroreaktorsystem aus ultraschallheißgeprägten Polymerfolien. Chem Ing Techn, early view, Feb 2015

Yue J, Luo L, Gonthier Y, Chen G, Yuan Q (2008) An experimental investigation of gas–liquid two-phase flow in single microchannel contactors. Chem Eng Sci 63:4189–4202

Zhao C-H (2013) Multiphase flow microfluidics for the production of single or multiple emulsions for drug delivery. Adv Drug Deli Rev 65:1420–1446

Zhao C-X, Middelberg APJ (2011) Two-phase microfluidic flows. Chem Eng Sci 66:1394–1411

Acknowledgments

The results presented here were partly achieved with the support of Deutsche Forschungsgemeinschaft with the support code SCHO 850/4 and by a scholarship provided by China Scholarship Council with award no. 2011683003.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liao, S., Sackmann, J., Tollkötter, A. et al. Ultrasonic fabrication of micro nozzles from a stack of PVDF foils for generating and characterizing microfluidic dispersions. Microsyst Technol 23, 695–702 (2017). https://doi.org/10.1007/s00542-015-2708-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2708-z