Abstract

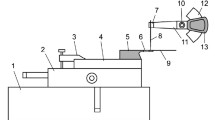

This paper presents a design, fabrication and performance of a silicon micro transmission system based on the micro electro-mechanical system technology. The system consists of six electrostatic shaking motors. With elastic structures and two ratchet mechanisms on both sides, the micro container (450 µm in length and 220 µm in width) can be driven forward with different velocities. The kinematic and force analyses of the system were performed in order to find out the moving condition of the container. The velocity of the micro container was tested with the driving frequencies up to 40 Hz at the driving voltage of V pp = 120 V and the obtained maximum displacement was about 2.2 mm. The micro transmission system with the cover size of 5 × 5 mm2 can be applied in bioengineering for carrying and classifying micro/nano samples, etc.

Similar content being viewed by others

References

Barnes SM, Miller SL, Rodgers MS, Bitsie F (2000) Torsional ratcheting actuating system, modeling and simulation of microsystems, San Diego, CA, 27–29 March 2000

Chien-Tai Wu, Hsu Wensyang (2006) Design and fabrication of an electrothermal microactuator for multi-level conveying. Microsyst Technol 12(4):293–298

Dario P et al (1992) Micro-actuators for microrobots: a critical survey. J Micromech Microeng 2:141–157

Ebefors T, Ulfstedt Mattsson J, Kalvesten E, Stemme G (2000) A robust micro conveyer realized by arrayed polyimide joint actuators. J Micromech Microeng 10:337–349

Fukuta Y, Yanada M, Ino A, Mita Y, Chapuis YA, Konishi S, Fujita H (2004) Conveyor for pneumatic two-dimensional manipulation realized by arrayed mems and its control. J Robot Mechatron 16(2):163–170

Hayashi T (1994) Micro-mechanisms and their characteristics. In: Proceedings of IEEE workshop on MEMS ’94, pp 39–44. ISBN 0-7803-1833-1

Hayashi T (2000) Research and development of micro-mechanisms. J Ultrason 38:6–14

Hwang IH, Lee YG, Lee JH (2006) A micromachined friction meter for silicon sidewalls with consideration of contact surface shape. J Micromech Microeng 16:2475–2481

Kim Y-K, Katsurai M, Fujita H (1990) Fabrication and testing of a micro superconducting actuator using the Meissner effect. In: Proceedings IEEE 3rd International workshop on micro electro mechanical systems (MEMS’90), Napa Valley, 11–14 February 1990, pp 61–66

Kim SH, Hwang IH, Jo KW, Yoon ES, Lee JH (2005) High-resolution inchworm linear motor based on electrostatic twisting microactuators. J Micromech Microeng 15:1674–1682

Konishi S, Fujita H (1994) A conveyance system using air flow based on the concept of distributed micro motion systems. IEEE J MicroElectroMech Syst 3(2):54–58

Liu C, Tsai T, Tai YC, Liu W, Will P, Ho CM (1995) A micromachined permalloy magnetic actuator array for micro robotics assembly systems. In: Proceedings of international conference on solid-state sensors and actuators Transducers ’95, vol 1, pp 328–331

Mehregany M, Tai YC (1991) Surface micro-machined mechanisms and micromotors. J Micromech Microeng 1:73–85

Nakazawa H, Wantanabe Y, Morita O, Edo M, Yushina M, Yonezawa E (1999) Electromagnetic micro-parts conveyer with coil–diode modules. Tech. Digest. In: 10th International conference of solid-state sensors and actuators (Transducers ’99), Sendai, Japan, 7–10 June 1999, pp 1192–1195

Pham PH, Dao DV, Amaya S, Kitada R, Sugiyama S (2006) Straight movement of micro containers based on Ratchet mechanisms and electrostatic comb-drive actuators. J Micromech Microeng 16(12):2532–2538

Pham PH, Dao DV, Sugiyama S (2007) Micro transportation system (MTS) with large movement of containers driven by electrostatic comb-drive actuators. J Micromech Microeng 17(10):2125–2131

Pham PH, Dang LB, Vu HN (2010) Micro robot system with moving micro-car driven by electrostatic comb-drive actuators. Microsyst Technol 16(4):505–510

Phuc HP, Dzung VD (2013) A micro gearing system based on a ratchet mechanism and electrostatic actuation. In: Microsystem technologies, vol 19(2). Springer, Berlin, pp 261–267

Polosky MA, Garcia EJ, Allen JJ (1998) Surface micro-machined counter-meshing gears discrimination device. Annual Symposium on Smart Structures and Materials, San Diego, CA, 1–3 March 1998

Sacks E, Barnes SM (2001) Computer-aided kinematic design of a torsional ratcheting actuator. In: Proceedings of the 4th international conference on modeling and simulation of microsystems, Hilton Head

Shibaike N (1995) Design of micro-mechanisms focusing on configuration, materials and processes. Mater Des 16(2):83–90

Sniegowski JJ, Garcia EI (1996) Surface-micromachined gear trains driven by an on-chip electrostatic microengine. IEEE Electron Device Lett 17(7):366–368

Steven Rogers M (1998) Designing and operating electrostatically driven microengines. In: Proceedings of the 44th international instrumentation symposium, Reno, NV, 3–7 May 1998, pp 56–65

Suh J, Glader S, Darling R, Storment C, Kovacs G (1997) Organic thermal and electrostatic ciliary microactuator array for object manipulation. Sens Actuators A 58:51–60

Tanner DM (2001) Reliability of a MEMS torsional ratcheting actuator. In: 39th Annual IEEE international reliability physics symposium, Orlando, Florida, pp 81–90

Acknowledgments

This research is funded by Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant Number “107.01-2013.07”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pham, P.H., Dang, L.B., Nguyen, D.T. et al. A micro transmission system based on combination of micro elastic structures and ratchet mechanism. Microsyst Technol 23, 381–387 (2017). https://doi.org/10.1007/s00542-015-2679-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2679-0