Abstract

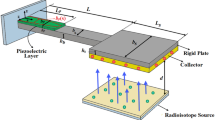

Piezoelectric micro-power generator (PMPG) converts mechanical vibration energy into electric energy via piezoelectric effects. In cardiac pace makers, the use of PMPG eliminates the need for a traditional lithium iodide battery replacement. In this paper we design and optimize PMPG that is able to harvest the mechanical movement of the heart beat to be converted into usable electrical power in frequency range 1–1.7 Hz. Eight control parameters are selected: which are proof mass material, piezoelectric material, proof mass length, proof mass thickness, piezoelectric layer width, piezoelectric layer thickness, silicon nitride layer width, silicon nitride layer thickness. Orthogonal arrays of Taguchi method for these eight parameters mentioned with three levels and signal-to-noise (S/N) ratio, and ANOVA analysis is studied to determine the optimum design. COMSOL Multiphysics ver. 4.2 is used in 18 different simulations. The maximum output power and highest efficiency designed at 1.2 Hz is equivalent to 72 beat per min. Both Taguchi and ANOVA confirms the same results of determining the parameter of having the most influence on the generated output power at 1.2 Hz in descending order: which are piezoelectric material of PZT-5A, proof mass length of 5 mm, piezoelectric layer thickness of 30 µm, proof mass thickness of 4 mm, piezoelectric layer width of 0.12 mm, silicon nitride layer width of 0.16 mm, silicon nitride layer thickness of 30 µm, and proof mass material of aluminum. Eigen frequency analysis for the first six modes of operation for PMPG frequencies are: 1.2 HZ, 5.4 Hz, 6.9 Hz, 29,7 Hz, 694.8 Hz, 708.3 Hz. The first mode of operation is selected as operation mode and shows that 93 % of PMPG’s total displacement and output power was produced in the range of 1–1.4 Hz, therefore PMPG can work when the heart rate between 60 and 84 bpm. Transient analysis performed at 1.2 Hz reaches the steady state before the first 10 cycles with output power density of 23.13 µW/cm3, which is suitable for powering cardiac pace maker.

Similar content being viewed by others

References

Amin Karami M, Inman DJ (2012) Powering pacemakers from heartbeat vibrations using linear and nonlinear energy harvesters. App Phy Lett 100(4):042901–042904. doi:10.1063/1.3679102

Campbell GA, Mutharasan R (2005) Detection of pathogen Escherichia coli O157:H7 using self-excited PZT-glass microcantilevers. Biosens Bioelectron 21:462–473

COMSOL 3.2. (2005) Structural mechanics. Manual, Comsol, AB, Sweden

Görge G, Kirstein M, Erbel R (2001) Microgenerators for energy autarkic pacemakers and defibrillators: fact or fiction? Herz 26(1):64–68

Hudak NS, Amatucci GG (2008) Small-scale energy harvesting through thermoelectric, vibration, and radiofrequency power conversion. J Appl Phys 103:101301

Jeon YB, Sood R, Jeong JH and S.-G kim (2005) “MEMS power generator with transverse mode thin film PZT “, Sensor and Actuators, pp. 16–22

Kansal A, Srivastava MB (2005) Distributed energy harvesting for energy-neutral sensor networks. IEEE Pervasive Comput 4:69–70

Kim H, Tadesse Y, Priya S (2009) Piezoelectric energy harvesting. In: Priya S, Inman DJ (eds) Energy harvesting technologies. Springer, New York

Laura PAA, Pombo JL, Susemihl EA (1974) A note on the vibrations of a clamped-free beam with a mass at the free end. J Sound Vib 37(2):161–168

Lindman H (1992) Analysis of variance in experimental design. Springer-Verlag, New York

Liu H et al (2011) A MEMS-based piezoelectric cantilever patterned with PZT thin film array for harvesting energy from low frequency vibrations. Phy Proced 19:129–133

Mustafa HAB, Kahn MTE (2009) “Microstructure cantilever beam for current measurement”. S Afr J Sci 105

O’Rouke RA, Fuster V (2001) Hurst’s the heart [10 (International edition) ed.], McGraw-Hill, ISBN 0-07-116296-8

Ross PJ (1996) Taguchi techniques for quality engineering. McGraw-Hill International Editions, Singapore

Roundy S, Wright PK, Rabaey J (2003) A study of low level vibrations as a power source for wireless sensor nodes. Comput Commun 26:1131–1144

Roundy S, Leland ES, Baker J, Carleton E, Reilly E, Lai E, Otis B, Rabaey JM, Wright PK, Sundararajan V (2005) Improving power output for vibration-based energy scavengers. IEEE Pervasive Comput 4:28–36

Rufer L, Colin M, Basrour S (2013) “Application driven design, fabrication and characterization of piezoelectric energy scavenger for cardiac pacemakers,” Applications of Ferroelectric and Workshop on the Piezoresponse Force Microscopy (ISAF/PFM), 2013 IEEE International Symposium on the, pp 340–343, doi:10.1109/ISAF.2013.6748687

Saadon S, Sidek O (2011) A review of vibration-based MEMS piezoelectric energy harvesters. Energy Convers Manag 52(1):500–504

Shen D (2009) Piezoelectric energy harvesting devices for low frequency vibration applications. PhD thesis, Auburn University

Starner T, Paradiso JA (2004) Human generated power for mobile electronics design. Low Power Electronics Design, vol 45

Taguchi G (1987) Hocheng Taguchi methods orthogonal arrays and linear graphs, tools for quality engineering. American Supplier Institute, Dearborn, pp 35–38

Taguchi G (1990) Introduction to quality engineering. Asian Productivity Organization, Tokyo

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tool Manuf 44:1085–1090

Viswanathan PC et al (2006) Recreating an artificial biological pacemaker: insights from a theoretical model. Heart Rhythm 3(7):824–831

Yang WH, Tarng YS (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method, J Mater Process Technol 84:122–129

Zhu D, Beeby S (2011) Kinetic energy harvesting. In: Energy harvesting systems: principles, modeling and applications, Springer, New York Dordrecht Heidelberg London, pp 1–78, ISBN 978-1-4419-7565-2

Acknowledgments

The authors would like to thank University Kebangsaan Malaysia for supporting this project under grant UKM-GUPNBT-08-25-084.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alrashdan, M.H.S., Hamzah, A.A. & Majlis, B. Design and optimization of cantilever based piezoelectric micro power generator for cardiac pacemaker. Microsyst Technol 21, 1607–1617 (2015). https://doi.org/10.1007/s00542-014-2334-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2334-1