Abstract

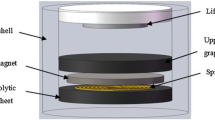

An energy harvesting system designed in this paper is of electromagnetic linear-motion inertial type that is capable of converting kinetic energy into useful electrical energy. The harvester consists of moving magnet–iron poles enclosed by cylindrical coils and an iron stator, and two stationary magnets are placed at both end sides acting as spring. The developed energy harvester is to be used for outdoor power equipment such as lawnmower and snow blower. Preliminary vibrational analysis is conducted on the lawnmower and snow blower to determine its working frequency and the optimal point of vibration. It was determined that the lawnmower resonated at a frequency of 15 Hz while the snow blower resonated at 21 Hz. Two methods are used to tune the energy harvesting system. The first is changing the stationary magnet thickness while keeping the magnet air gap constant and second is changing the air gap while keeping the stationary magnet thickness constant. We found that it is optimal to change the air gap rather than the magnet thickness to change the natural frequency of the device. The energy harvesting system is tuned to work on a lawnmower where the natural frequency is 15 Hz. Natural frequency of 15 Hz is obtained when the magnet thickness is 9.525 mm and a gap of 70.75 mm, where the maximum power dissipated is 29 mW.

Similar content being viewed by others

References

Beeby SP, Tudor MJ, White NM (2006) Energy harvesting vibration sources for microsystems applications. Meas Sci Technol 17(12):R175–R195

Beeby SP, Torah RN, Tudor MJ, Glynne-Jones P, O’Donnell T, Saha CR, Roy S (2007) A micro electromagnetic generator for vibration energy harvesting. J Micromech Microeng 17(7):1257–1265

Glynne-Jones P et al (2004) An electromagnetic, vibration-powered generator for intelligent sensor systems. Sens Actuators A 110:344–349

Lee C, Stamp D, Kapania N, Mur-Miranda JO (2010) Harvesting vibration energy using nonlinear oscillations of an electromagnetic inductor. http://digitalcommons.olin.edu/facpres_2010/1

Mann BP, Sims ND (2009) Energy harvesting from the nonlinear oscillations of magnetic levitation. J Sound Vib 319:515–530

Mitcheson PD et al (2004) Architectures for vibration-driven micropower generators. JMEMS 13(3):429–440

Patel P, Khamesee MB (2013) Electromagnetic micro energy harvester for human locomotion. Microsyst Technol 19:1357–1363

Acknowledgments

The authors would like to acknowledge and thank Prof. A. Salehian in Mechanical Engineering Department at University of Waterloo for providing the shaker.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patel, P., Khamesee, M.B. Microenergy harvesting applications for outdoor power equipment. Microsyst Technol 20, 1715–1722 (2014). https://doi.org/10.1007/s00542-014-2213-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2213-9