Abstract

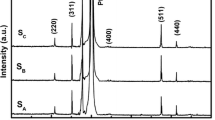

In this paper, thin film Pt temperature microsensor in the temperature range of 10–100 K for cryogenic engineering applications is proposed and researched. The sensor is designed with two structures, and they are obtained by micro fabrication technology. The sensors are annealed in different conditions. The degree crystallization and grain size are analyzed by X-ray diffraction and SEM for both as-deposited and annealed sensors. The resistance dependency on temperature test result shows that when temperature is larger and smaller than 50 K, the average temperature coefficient resistance (TCR) of rectangular shape sensor could achieve 3,118 ppm/K and above 257 ppm/K, respectively. Meanwhile, TCR of circular shape sensor is 2,778 ppm/K and above 249 ppm/K, respectively. The good thermal cycle stability is observed. After three cycles between 10 and 100 K, the maximum resistance variation values are 0.0034 and 0.0137 %, which correspond to 0.0082 and 0.061 K temperature shift for the rectangular and circular sensors, respectively. The ΔT/T (%) of rectangular and circular sensors is performed with the magnetic field up to 6T in the temperature range of 10–100 K, and they are within the range of −19.84 to 0.137 and −2.18 to 11.33 for rectangular and circular sensors,respectively. The impedance test shows that the sensors have the same electric properties under direct current and alternating current condition.

Similar content being viewed by others

References

Jeng JS, Chen JS (2009) Effect of substrate bias and nitrogen flow ratio on the surface morphology and binding state of reactively sputtered ZrNx films before and after annealing. Appl Surf Sci 255:8263–8269

Lan KC, Huang JH, Ai CF, Yu GP (2011) Structure and properties of nanocrystalline ZrNxOy thin films: effect of the oxygen content and film thickness. J Vac Sci Technol A 29:031506

Lee Chi-Yuan, Wu Guan-Wei, Hsieh Wei-Jung (2008) Fabrication of micro sensors on a flexible substrate. Sens Actuators A 147:173–176

Liu CP, Yang HG (2003) Systematic study of the evolution of texture and electrical properties of ZrNx thin films by reactive DC magnetron sputtering. Thin Solid Films 444:111–119

Mayadas AF, Shatzks M (1970) Electrical-resistivity model for polycrystalline film: the case of arbitrary reflection at external surfaces. Phys Rev B (solid state) 1:1382–1389

Mitin VF (1999) Resistance thermometers based on the germanium films. Semicond Phys Quantum Electron Optoelectron 2:115–123

Mitin VF (2008) Heavily doped and fully compensated Ge single-crystalline films on GaAs. Appl Phys Lett 92:202111

Mitin VF (2010) Preparation and properties of heavily doped and strongly compensated Ge films on GaAs. J Appl Phys 107:033720

Mitin VF, Tkhorik YA, Venger EF (1997) All-purpose technology of physical sensors on the base of Ge/GaAs heterostructures. Microelectron J 28:617–625

Mitin VF, Venger EF, Boltovets NS (1998) Low-temperature Ge film resistance thermometers. Sens Actuators A 68:303–306

Mitin VF, McDonld PC, Pavese F (2007) Ge-on-GaAs film resistance thermometers for cryogenic applications. Cryogenics 47:474–482

Mitin VF, Kholevchuk VV, Kolodych BP (2011) Ge-on-GaAs film resistance thermometers: low-temperature conduction and magnetoresistance. Cryogenics 51:68–73

Moser Y, Gijs MAM (2007) Miniaturized flexible temperature sensor. J Microelectromech Syst 16:1349–1354

Rajagopal A, Walavalkar S, Chen S, Guo L, Gwinn T, Scherer A (2010) Microscaled and nanoscaled platinum sensors. Appl Phys Lett 97:133109

Resnik D, Vrtaccaronnik D, Aljanccaroniccaron U, Mozaronek M, Peccaronar B, Penic S, Amon S (2009) Characterization of integrated thin film Pt heater and temperature sensors on Si platform. IEEE industrial electronics 35th annual conference, Porto, 4014–4019

Roman D, Bernardi J, de Amorim CLG, Cintia LG (2011) Effect of deposition temperature on microstructure and corrosion resistance of ZrN thin films deposited by DC reactive magnetron sputtering. Mater Chem Phys 130:147–153

Yoshitake M (1990) Synthesis of Zr–N thin film by reactive ion beam sputtering. Jpn J Appl Phys 29:2800–2808

Yotsuya T, Yoshitake M, Kodama T (1997) Low-temperature thermometer using sputtered ZrNx thin film. Cryogenics 37:817–822

Acknowledgments

This work is partly supported by the National Natural Science Foundation of China (No. 61076107), the Science and Technology Department of Shanghai (No. 11DZ2290203, 11JC1405700), Program for New Century Excellent Talents in University (2009). The authors are also grateful to the colleagues for their essential contribution to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, SD., Liu, JQ., Yang, B. et al. Microfabrication of thin film temperature sensor for cryogenic measurement. Microsyst Technol 20, 451–456 (2014). https://doi.org/10.1007/s00542-013-1982-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1982-x