Abstract

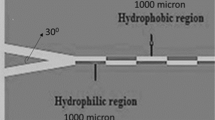

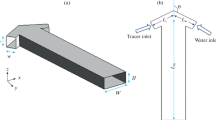

Surface roughness effects are dominant at microscale. In this study, microchannels are fabricated on Silicon substrate. The roughness morphology is modeled for the fabricated structure using Weierstrass-Mandelbrot function for self-similar fractals. A two dimensional model of hexagonal passive micromixer is analyzed with surface roughness present on inner walls of channels using parallel Lattice Boltzmann method, implemented on sixteen node cluster. The results are compared by simulating this micromixer structure using Navier–Stokes equations. The experimental results on the fabricated micromixers are also presented. The effects of relative roughness, fractal dimension and Reynolds number are discussed on laminar flow in hexagonal passive micromixers. The study concludes the importance of modeling surface roughness effect for better mixing efficiency.

Similar content being viewed by others

References

Bhagat AAS, Papautsky I (2008) Enhancing particle dispersion in a passive planar micromixer using rectangular obstacles. J Micromech Microeng 18: 085005 doi:10.1088/0960-1317/18/8/085005

Bahrami M, Yovanovich MM, Culham JR (2006) Pressure drop of fully-developed, laminar flow in microchannels of arbitrary cross-section. J Fluids Eng 128(5):1036–1044. doi:10.1115/1.2234786

Barrat JL, Bocquet L (1999) Large slip effect at a nonwetting fluid–solid interface. Phys Rev Lett 82:4671

Bau HH, Zhong J, Yi M (2001) A minute magneto hydrodynamic (MHD) mixer. Sens Actuators B 79(2-3):205–213

Bhagat A, Papautsky I (2008) Enhancing particle dispersion in a passive planar micromixer using rectangular obstacles. J Micromech Microeng 18: 085005. http://dx.doi.org/10.1088/0960-1317/18/8/085005

Croce G, D’Agaro P (2005) Numerical simulation of roughness effect on microchannel heat transfer and pressure drop in laminar flow. J Phys D Appl Phys 38:1518–1530

Daghighi Y, Li D (2013) Numerical study of a novel induced-charge Electrokinetic micromixer. Anal Chim Acta 763:28–37

Karniadakis G, Beskok A, Aluru N (2005) Microflows and Nanoflows: fundamentals and simulation. Springer Publication

Gobby D, Angeli P, Gavriilidis A (2001) Mixing characteristics of T-type microfluidic mixers. J Micromech Microeng 11:126–132

Heinbuch U, Fischer J (1989) Liquid flow in pores: slip, no-slip, or multilayer sticking. Phys Rev A 40:1144

Kleinstreuer C, Koo J (2004) Computational analysis of wall roughness effects for liquid flow in micro-conduits. J Fluids Eng 126(1):1–9. doi:10.1115/1.1637633

Li C, Chen T (2005) Simulation and optimization of chaotic micromixer using lattice Boltzmann method. Sens Actuators B 106:871–877

Majumdar A, Tien CL (1990) Fractal characterization and simulation of rough surfaces. Wear 136:313–327

Ansari MA, Kim1 K-Y, Anwar K, Kim SM (2010) A novel passive micromixer based on unbalanced splits and collisions of fluid streams. J Micromech Microeng 20: 055007. doi:10.1088/0960-1317/20/5/055007

Nguyen N-T (2008) Micromixer: fundamentals, design and fabrication, William Andrew Inc

Okkels F, Tabeling P (2004) Spatiotemporal resonances in mixing of open viscous fluidics. Phys Rev Lett 92:038301

Patrikar R (2004) Modeling and simulation of surface roughness. Appl Surf Sci 228:213–220

Succi S (2001) The Lattice Boltzmann equation for fluid dynamics and beyond, Oxford University Press

Sukop MC, Thorne DT (2006) Lattice Boltzmann Modeling, Springer, Berlin

Sun M, Ebner C (1992) Molecular dynamics study of flow at a fluid-wall interface. Phys Rev Lett 69:3491

Travis KP, Todd BD, Evans DJ (1997) Departure from Navier–Stokes hydrodynamics in confined liquids. Phys Rev E 55:4288

Tsai JH, Lin L (2002) Active microfluidic mixer and gas bubble filter driven by thermal bubble micropump. Sens Actuat A-Phys 97–98:665–671

Wong SH, Ward MCL, Wharton CW (2004) Micro T-mixer as a rapid mixing micromixer. Sens Actuators B 100:365–385

Wu JJ (2000) Simulation of rough surfaces with FFT. Tribol Int 33(1):47–58

Wu Z, Nguyen NT, Huang XY (2004) Non-linear diffusive mixing in microchannels: theory and experiments. J Micromech Microeng 14:04. doi:10.1088/0960-1317/14/4/022

Yaralioglu GG, Wygant IO, Marentis TC, Khuri-Yakub BT (2004) Ultrasonic mixing in microfluidic channels using integrated transducers. Anal Chem 76(13):3694–3698. doi:10.1021/ac035220k

Yong Shi, Zhao TS, Guo ZL (2006) Lattice Boltzmann method for incompressible flows with large pressure gradients. Phys Rev E 73:026704

Zhu YX, Granick S (2002) Limits of the hydrodynamic no-slip boundary condition. Phys Rev Lett 88:106102

Acknowledgments

The authors would like to thank VNIT for their continued support. Authors would like to thank ADA for providing the necessary CAD tools through NPMASS initiative. Authors are grateful to CEN, IIT Bombay and Department of Mechanical Engineering, IIT Bombay for providing the opportunity to carry out fabrication of microfluidic devices.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pendharkar, G., Deshmukh, R. & Patrikar, R. Investigation of surface roughness effects on fluid flow in passive micromixer. Microsyst Technol 20, 2261–2269 (2014). https://doi.org/10.1007/s00542-013-1957-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1957-y