Abstract

This paper proposes a slit-resonant beam based on the double clamped resonant beam theory of silicon micro-machined resonant pressure sensors. The slit structure can enhance surface alternating stress in the root area of beam while vibrating. Finite element method (FEM) is applied to calculate the stress concentration magnification, and we carry out a computational study of the effects of size and location of slit structure in terms of mechanical properties of resonant beam, such as stress concentration on resonant beam and natural frequency of resonant beam, as well as sensing performance, such as resonant beam amplitude sensitivity. Our simulations show that the slit structure could strengthen the stress concentration and increase the amplitude detection sensitivity, and the variations of these parameters can substantially influence the performance of slit structure. The research of stress concentration, caused by silt structure, could provide reference for further optimization and design for the resonant beam.

Similar content being viewed by others

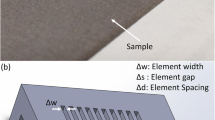

Abbreviations

- L :

-

Length of the resonant beam

- B :

-

Width of the resonant beam

- H :

-

Thickness of the resonant beam

- l :

-

Length of slit

- b :

-

Width of slit

- h :

-

Thickness of slit

- s :

-

Space distance of two slits

- d :

-

The distance of slit location from the resonant beam clamped end

- l/b :

-

Aspect ratio (length/width) of the slit

- R sc :

-

Average stress magnification radio

- R rsc :

-

Reference average stress magnification radio

- F nfr :

-

Natural frequency ratio

- \( A_{R} \) :

-

Single side cross-sectional area of the U-shaped detection resistor

- \( \pi_{L} \) :

-

Longitudinal piezoresistive coefficient

- \( \pi_{T} \) :

-

Transverse piezoresistive coefficient

- \( \sigma_{L} \) :

-

Longitudinal stress of the detection resistor

- \( \sigma_{T} \) :

-

Transverse stress of the detection resistor

- \( S_{d} \) :

-

Amplitude detection sensitivity

- \( \varepsilon \left( \omega \right) \) :

-

Rate of detection resistance variation

References

Ahmed ASM, Walied AM, Edmond L (2010) Optimization of geometric Characteristics to improve sensing performance of MEMS Piezoresistive strain sensor. J Micromech Microeng 20:015015. doi:10.1088/0960-1317/20/1/015015

Bashir R, Gupta A, Neudeck GW, McElfresh M (2000) On the design of piezoresistive silicon cantilevers with stress concentration regions for scanning probe microscopy applications. J Micromech Microeng 10:483–491. doi:10.1088/0960-1317/10/4/301

Bouwstra S, Legtenberg R, Tdmans H A C and Elwenspoek M (1990) Resonating microbridge mass flow sensor. J Sens Actuators A21–A23: 332–335. doi:10.1016/0924-4247(90)85066-D

Heller SR, Brock JS, Bart R (1958) The stresses around a rectangular opening with rounded corners in a uniformly loaded plate[C]. In: proceedings of the Third US National Congress of Applied Mechanics, ASME, pp 357–368

Joshi BP, Chaware AS, Gangal SA (2007) Optimising Performance of a cantilever-type micro accelerometer sensor. Def Sci J 57(3):261–269

Kovacs G (1998) Micromachined Transducers Sourcebook. McGraw-Hill, New York

Lammerink TSJ, Elwensfqek M, Ouwerkerk RHV, Bouwstra S, Fluitman JHJ (1990) Performance of thermally excited resonators. J Sens Actuators 21:352–356. doi:10.1016/0924-4247(90)85070-K

Langdon RM (1985) Resonator sensors—a review. J Phys E Sci Instrum 18:103–115. doi:10.1088/0022-3735/18/2/002

Mo Y, Xuan Z, Kambiz V, Cengiz SO (2003) High sensitivity Piezoresistive cantilever design and optimization for analyte-receptor binding. J Micromech Microeng 13:64–72. doi:10.1088/0960-1317/13/6/309

Pilkey WD, Pilkey DF (2008) Peterson’s Stress concentration factors 3rd edn. Wiley, New York

Qingfeng L, Shangchun F, Zhangyang T, Weiwei X (2012) Non-linear dynamics of an electrothermally excited resonant pressure sensor. J Sens Actuators A: Phys (in press). doi:10.1016/j.sna.2012.01.006

Smith CS (1954) Piezoresistance effect in germanium and silicon. J Phys Rev 94:42–49. doi:10.1103/PhysRev.94.42

Wdfinger RJ, Bardell PH, Chhabra DS (1968) The resonistor: a frequency selective device utilizing the mechanical resonance of a silicon substrate. IBM J Res Develop 12:113–118. doi:10.1147/rd.121.0113

Zhangyang T, Shangchun F, Weiwei X, Zhanshe G, Zhengyuan Z (2011) An electrothermally excited dual beams silicon resonant pressure sensor with temperature compensation. J Microsyst Technol 17:1481–1490. doi:10.1007/s00542-011-1319-6

Zienkiewicz OC, Taylor RL (2000) The Finite element method, 7th edn. Elsevier Science and Technology Books

Acknowledgments

This work is sponsored by the National Nature Science Fund of china with grant no. 60927005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, H., Fan, S., Xing, W. et al. Design and FEM simulation study of the electro-thermal excitation resonant beam with slit-structure. Microsyst Technol 19, 979–987 (2013). https://doi.org/10.1007/s00542-012-1682-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1682-y