Abstract

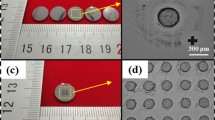

This paper presents ultrasonic embossing using silicon molds to replicate microstructures on Polymethyl Methacrylate (PMMA) substrates. The pattern of the silicon mold consists of micro grooves with different sizes. The molds were fabricated by wet etching, and both concave and convex types were fabricated. The effects of the processing parameters on replication quality, including average microstructure depth, uniformity and the location-related replication depth were investigated via orthogonal experiments. The results show that the ultrasonic amplitude is the most important parameter for replication depth. The ultrasonic time benefits the accumulation of the heat, so it also influences replication depth. As for ultrasonic force, it has less influence on replication depth but significant influence on replication uniformity. The width of the grooves of the high density patterning molds ranged from 10 to 30 μm, and the center distance between the two microstructures from 20 to 50 μm in our experiments. The concave molds were intended to reach higher replication depth than that of convex molds with the same micro grooves. The average replication depth reached 98 %, and the uniformity on one chip reached 99 % with an area of 11 × 11 mm. All experiments were finished in 60 s, which is more efficient than the hot embossing technique, thus this paper provides a potential method for medium-sized bulk production and rapid fabrication for polymer microcomponents.

Similar content being viewed by others

References

Attia UM, Marson S, Alcock JR (2009) Micro-injection moulding of polymer microfluidic devices. J Microfluid Nanofluid 7:1–28

Lan SH, Lee HJ, Ni J, Lee M, Choi S (2008) Experiment Study of micro hot-embossing process using GC mold and PC substrate. In: International conference on smart manufacturing application, ICSMA 2008, Gyeonggi-do, Korea, pp 377–382

Liu SJ, Dung YT (2005) Hot Embossing Precise Structure onto Plastic Plates by Ultrasonic Vibration. J Polym Eng Sci 45:915–925

Liu SJ, Huang YC, Yang SY, Hsieh KH (2010) Rapid fabrication of surface-relief plastic diffusers by ultrasonic embossing. J Opt Laser Technol 42:794–798

Mekaru H, Nakamura O, Maruyama O, Maeda R, Hattori T (2007) Development of precision transfer technology of atmospheric hot embossing by ultrasonic vibration. J Microsyst Technol 13:385–391

Yu HW, Lee CH, Jung PG, Shin BS, Kim JH, Hwang KY, Ko JS (2009a) Polymer microreplication using ultrasonic vibration energy. J Micro/Nanolithography MEMS MOEMS 8(2):11–13

Yu H, Zhou G, Chau FS, Lee F (2009b) Fabrication and characterization of PDMS microlenses based on elastomeric molding technology. J Opt lett 34:3454–3456

Zhang Z, Wang X, Luo Y, Zhang Z, Wang L (2009) Study on Heating Process of Ultrasonic Welding for Thermoplastics. J Thermoplast Compos Mater 23:647–664

Acknowledgments

The authors wish to gratefully acknowledge the financial support provided for this study by National Natural Science Foundation of China (50975037), the State Key Development Program for Basic Research of China (Grant No. 2011CB013105), the Fundamental Research Funds for the Central Universities (DUT12ZD212), and the Scientific Research Foundation for the Returned Overseas Chinese Scholars (State Education Ministry, [2010]1174).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, N., Luo, Y., Yan, X. et al. Using silicon molds for ultrasonic embossing on Polymethyl Methacrylate (PMMA) substrates. Microsyst Technol 19, 609–616 (2013). https://doi.org/10.1007/s00542-012-1671-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1671-1