Abstract

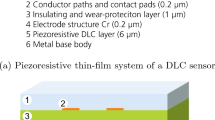

The investigation of a novel sensor system, integrated in the main load region of forming machines, is the challenge. Therefore, it is important that the thin film system has an excellent tribological quality in combination with a piezoresistive behaviour. The layer system is deposited on the polished surface of a steel substrate. It has such geometries that it can be easily integrated in the drawing cushion of a deep drawing machine. The thin film sensor system exists out of a piezoresistive hydrogenated carbon layer. Onto this layer arrays of chromium structures are deposited. The structures are protected against wear by an insulating silicon doped hydrogenated carbon layer. The whole thin film system has a thickness of about 9 μm. During the forming process the steel plate is in direct touch with the sensor system and moves over it. The position of the steel is measured in dependence on the forming stadium. The sensor system works as a control system to ensure that the shape of the product is perfect and without any cracks or creases.

Similar content being viewed by others

References

Bewilogua K, Bialuch I, Brand J, Keunecke M, Ruske H, Thomsen H, Weber M, Wittorf R (2006) DLC based coatings for tribological applications. In: Nihar Ranjan Ray (ed) Proceedings of international workshop on applications of nanocrystalline diamond and diamond like carbon materials, pp 67–75

Biehl S, Lüthje H, Bandorf R, Sick JH (2006) Multifunctional thin film sensors based on amorphous diamond-like-carbon for use in tribological applications. Thin Solid Films 515(3):1171–1175

Breitling J, Altan T (1996) In-die load sensing and process control, Project report S 1.4 of the Ohio State University

Neubert J, Ortmann S, Albert A (2008) Jedes Teil wie es sein soll––stabile Bauteilqualität aus sensorbestückten Umformwerkzeugen. Karlsruher Arbeitsgespräche Produktionsforschung, pp 160–166

Neugebauer R, Bräunlich H, Scheffler S (2008) Process monitoring and closed loop controlled process. In: Proceedings of the Conference “Advanced Metal Forming Processes in Automotive Industry” 2008, Wroclaw, pp 21–41

Robertson J (2003) Improving the properties of diamond-like-carbon. Diam Relat Mater 12:79–84

Spur G, Thoms V, Liewald M, Straube O (1994) Regelung des Tiefziehprozesses in der Preßteilefertigung mit dem Blechkanteneinlauf als Regelgröße. Blech Rohre Profile Bamberg 41:237–240

Straube O (1994) Untersuchungen zum Aufbau einer Prozessregelkette für das Ziehen von Karosserieteilen. Ph.D. thesis, Berlin, Carl-Hanser-Verlag, München, Wien

Acknowledgments

This work is supported by the german federal ministry of education and research with the support code 02PU2040.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biehl, S., Staufenbiel, S., Hauschild, F. et al. Novel measurement and monitoring system for forming processes based on piezoresistive thin film systems. Microsyst Technol 16, 879–883 (2010). https://doi.org/10.1007/s00542-010-1058-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-010-1058-0