Abstract

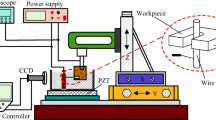

This paper reports on the fabrication of high aspect ratio silicon microelectrode arrays by micro-wire electrical discharge machining (μ-WEDM). Arrays with 144 electrodes on a 400 μm pitch were machined on 6 and 10 mm thick p-type silicon wafers to a length of 5 and 9 mm, respectively. Machining parameters such as voltage and capacitance were varied for different wire types to maximize the machining rate and to obtain uniform electrodes. Finite element analysis was performed to investigate electrode shapes with reduced lateral rigidity. These compliant geometries were machined using μ-WEDM followed by a two step chemical etching process to remove the recast layer and to reduce the cross sections of the electrodes.

Similar content being viewed by others

References

Bai Q, Wise KD, Anderson DJ (2000) A high-yield microassembly structure for three-dimensional microelectrode arrays. IEEE Trans Biomed Eng 47(3):281–289. doi:10.1109/10.827288

Bamberg E, Rakwal D (2008) Experimental investigation of wire electrical discharge machining of gallium-doped germanium. J Mater Process Technol 197(1–3):419–427. doi:10.1016/j.jmatprotec.2007.06.038

Fofonoff TA, Martel SM, Hatsopoulos NG, Donoghue JP, Hunter IW (2004) Microelectrode array fabrication by electrical discharge machining and chemical etching. IEEE Trans Biomed Eng 51(6):890–895. doi:10.1109/TBME.2004.826679

Guitrau EP (1997) The EDM handbook. Hanser Gardner Publications, Cincinnati

Heeren PH, Reynaerts D, Van Brussel H, Beuret C, Larsson O, Bertholds A (1997) Microstructuring of silicon by electro-discharge machining (EDM)—part II: applications. Sens Act A Phys 61(1–3):379–386

Hoogerwerf AC, Wise KD (1994) A three-dimensional microelectrode array for chronic neural recording. IEEE Trans Biomed Eng 41(12):1136–1146. doi:10.1109/10.335862

Jones KE, Campbell PK, Normann RA (1992) A glass/silicon composite intracortical electrode array. Ann Biomed Eng 20(4):423–437. doi:10.1007/BF02368134

Kunieda M, Ojima S (2000) Improvement of EDM efficiency of silicon single crystal through ohmic contact. Precis Eng 24(3):185–190. doi:10.1016/S0141-6359(99)00041-0

Kunieda M, Lauwers B, Rajurkar KP, Schumacher BM (2005) Advancing EDM through fundamental insight into the process. CIRP Ann Manuf Technol 54(2):599–622. doi:10.1016/S0007-8506(07)60020-1

Luo YF, Chen CG, Tong ZF (1992) Investigation of silicon wafering by wire EDM. J Mater Sci 27(21):5805–5810. doi:10.1007/BF01119742

Madou MJ (2002) Fundamentals of microfabrication, 2nd edn. CRC Press, New York

Orino C, Rakwal D, Jorgensen JD, Bamberg E (2006) Development of a precision, low-cost, small footprint wire electron discharge machine (WEDM). Proc 2006 ASPE Conf 26:239–242

Peng WY, Liao YS (2003) Study of electrical discharge machining technology for slicing silicon ingots. J Mater Process Technol 140:274–279. doi:10.1016/S0924-0136(03)00718-0

Rakwal D, Bamberg E (in press) Slicing, cleaning and kerf analysis of germanium wafers machined by wire electrical discharge machining. J Mater Process Technol. doi:10.1016/j.jmatprotec.2008.08.027

Reynaerts D, Meeusen W, Van Brussel H (1998) Machining of three-dimensional microstructures in silicon by electro-discharge machining. Sens Act A Phys 67(1–3):159–165

Schumacher BM (2004) After 60 years of EDM the discharge process remains still disputed. J Mater Process Technol 149:376–381. doi:10.1016/j.jmatprotec.2003.11.060

Song X, Meeusen W, Reynaerts D, Van Brussel H (2000) Experimental study of micro-EDM machining performances on silicon wafer. Proc SPIE Int Soc Opt Eng 4174:331–339

Takino H, Ichinohe T, Tanimoto K, Yamaguchi S, Nomura K, Kunieda M (2005) High-quality cutting of polished single-crystal silicon by wire electrical discharge machining. Precis Eng 29(4):423–430. doi:10.1016/j.precisioneng.2004.12.004

Acknowledgments

This material is based upon work supported by ProfX2 fellowship grant awarded to Prashant Tathireddy by Fraunhofer Gesellschaft, Germany and equipment developed with support from Optimation, LLC and the National Science Foundation under Grant No. 0512897.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rakwal, D., Heamawatanachai, S., Tathireddy, P. et al. Fabrication of compliant high aspect ratio silicon microelectrode arrays using micro-wire electrical discharge machining. Microsyst Technol 15, 789–797 (2009). https://doi.org/10.1007/s00542-009-0792-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-0792-7